Steel plate for marine ocean energy source equipment and preparation technique thereof

A preparation process and energy technology, applied in the steel plate for marine energy equipment and its preparation process, steel plate field, can solve the problems of reducing the fatigue fracture toughness of steel structures, accelerating crack initiation and expansion, affecting the safety of production operations, etc., to achieve ideal tensile strength Strength, good toughness, effect of improving yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

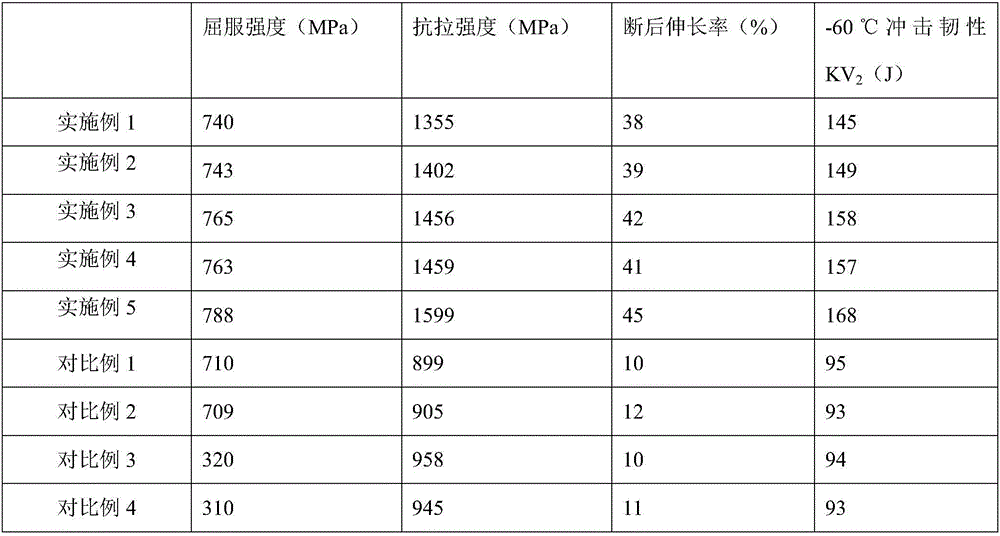

Examples

Embodiment 1

[0026] The steel plate for marine energy equipment in this embodiment is composed of the following chemical components in mass percentage: 0.21% carbon, 0.55% silicon, 0.15% aluminum, 0.001% boron, 1.00% chromium, 0.55% manganese, 0.009% phosphorus, sulfur 0.002%, molybdenum 2.5%, niobium 0.05%, vanadium 0.08%, and the balance is iron and unavoidable impurities.

[0027] The preparation process of the above-mentioned steel plate for marine energy equipment includes the steps of:

[0028] (1) Smelting is carried out according to the chemical composition of the recipe amount, and the cast blank is forged into a slab;

[0029] (2) The slab is subjected to conventional hot rolling, pickling, and cold rolling; the starting temperature of hot rolling is 1200°C, and the starting temperature of cooling is 800°C. After 8 passes of rolling, the cumulative deformation is above 70%, and water cooling after rolling, Air cooling to room temperature, after hot rolling, the steel plate is pi...

Embodiment 2

[0032] The steel plate for marine energy equipment in this embodiment is composed of the following chemical components in mass percentage: 0.33% carbon, 0.85% silicon, 0.22% aluminum, 0.002% boron, 1.45% chromium, 0.75% manganese, 0.013% phosphorus, sulfur 0.005%, molybdenum 3.5%, niobium 0.1%, vanadium 0.15%, the balance is iron and unavoidable impurities.

[0033] The preparation process of the above-mentioned steel plate for marine energy equipment includes the steps of:

[0034] (1) Smelting is carried out according to the chemical composition of the recipe amount, and the cast blank is forged into a slab;

[0035] (2) The slab is subjected to conventional hot rolling, pickling, and cold rolling; the starting temperature of hot rolling is 1200°C, and the starting temperature of cooling is 800°C. After 8 passes of rolling, the cumulative deformation is above 70%, and water cooling after rolling, Air cooling to room temperature, after hot rolling, the steel plate is pickled...

Embodiment 3

[0038] The steel plate for marine energy equipment in this embodiment is composed of the following chemical components in mass percentage: 0.25% carbon, 0.65% silicon, 0.16% aluminum, 0.001% boron, 1.11% chromium, 0.60% manganese, 0.010% phosphorus, sulfur 0.003%, molybdenum 2.8%, niobium 0.08%, vanadium 0.09%, and the balance is iron and unavoidable impurities.

[0039] The preparation process of the above-mentioned steel plate for marine energy equipment includes the steps of:

[0040] (1) Smelting is carried out according to the chemical composition of the recipe amount, and the cast blank is forged into a slab;

[0041] (2) The slab is subjected to conventional hot rolling, pickling, and cold rolling; the starting temperature of hot rolling is 1200°C, and the starting temperature of cooling is 800°C. After 8 passes of rolling, the cumulative deformation is above 70%, and water cooling after rolling, Air cooling to room temperature, after hot rolling, the steel plate is pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com