Leadless free-cutting tin-magnesium brass alloy

A brass alloy, easy-cutting technology, applied in the field of lead-free easy-cut antimony-magnesium brass alloy, can solve the problem of inferior cutting performance, and achieve the effect of excellent thermal processing performance, small grain size and good cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

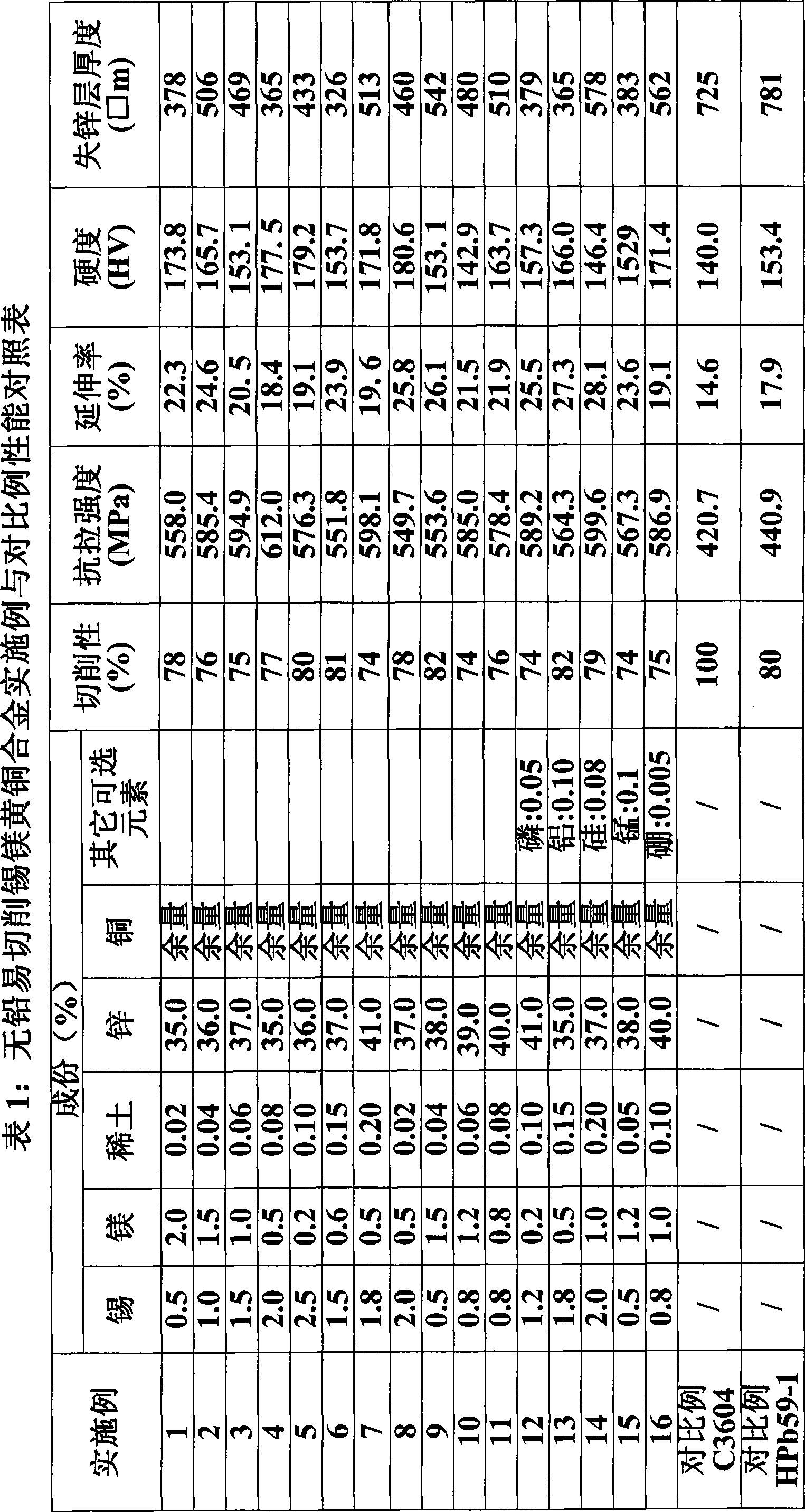

[0020] Table 1 below compares 16 examples of the present invention with existing conventional leaded brass C3604 and HPb59-1 to further illustrate the superior mechanical properties, corrosion resistance and cutting performance of the present invention.

[0021] The processing technology of the lead-free free-cutting antimony-magnesium brass alloy of the present invention is as follows: during smelting, copper-zinc smelting is first carried out at a temperature of 1050°C to 1250°C, and then copper-magnesium master alloy, antimony and rare earth, and other alloys are added Composition, heat preservation for 10min-40min, semi-continuous casting, casting temperature 1150℃~1200℃, ingot diameter Φ120mm. The ingot is heated at a temperature of 600°C-800°C, the holding time is 30min-90min, and then hot-extruded, extruded into a round bar with a size of Φ25.4mm, and then cold-drawn into a Φ24mm rod with a single-chain horizontal drawing machine. .4mm lead-free antimony-magnesium brass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com