Cutting device for waste cable recycling

A technology for waste cables and cables, applied in the field of wires and cables, can solve the problems of manpower consumption and low efficiency, and achieve the effect of reducing labor intensity, ensuring cutting effect and increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

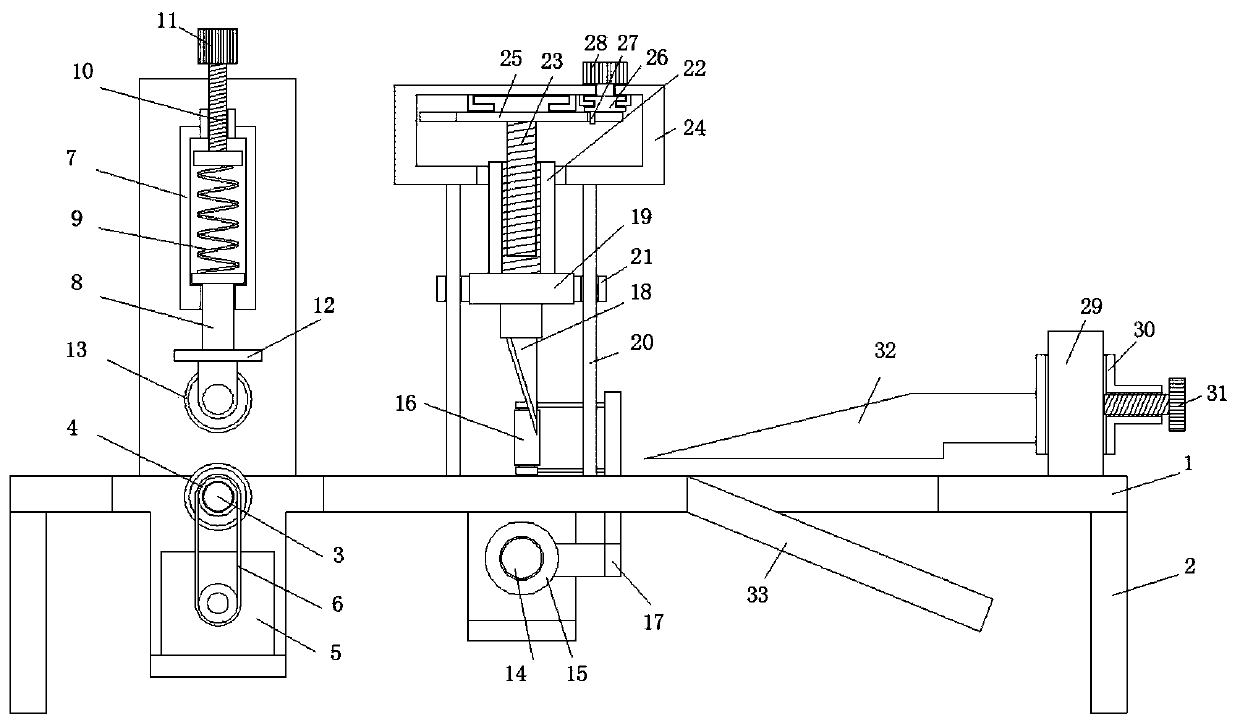

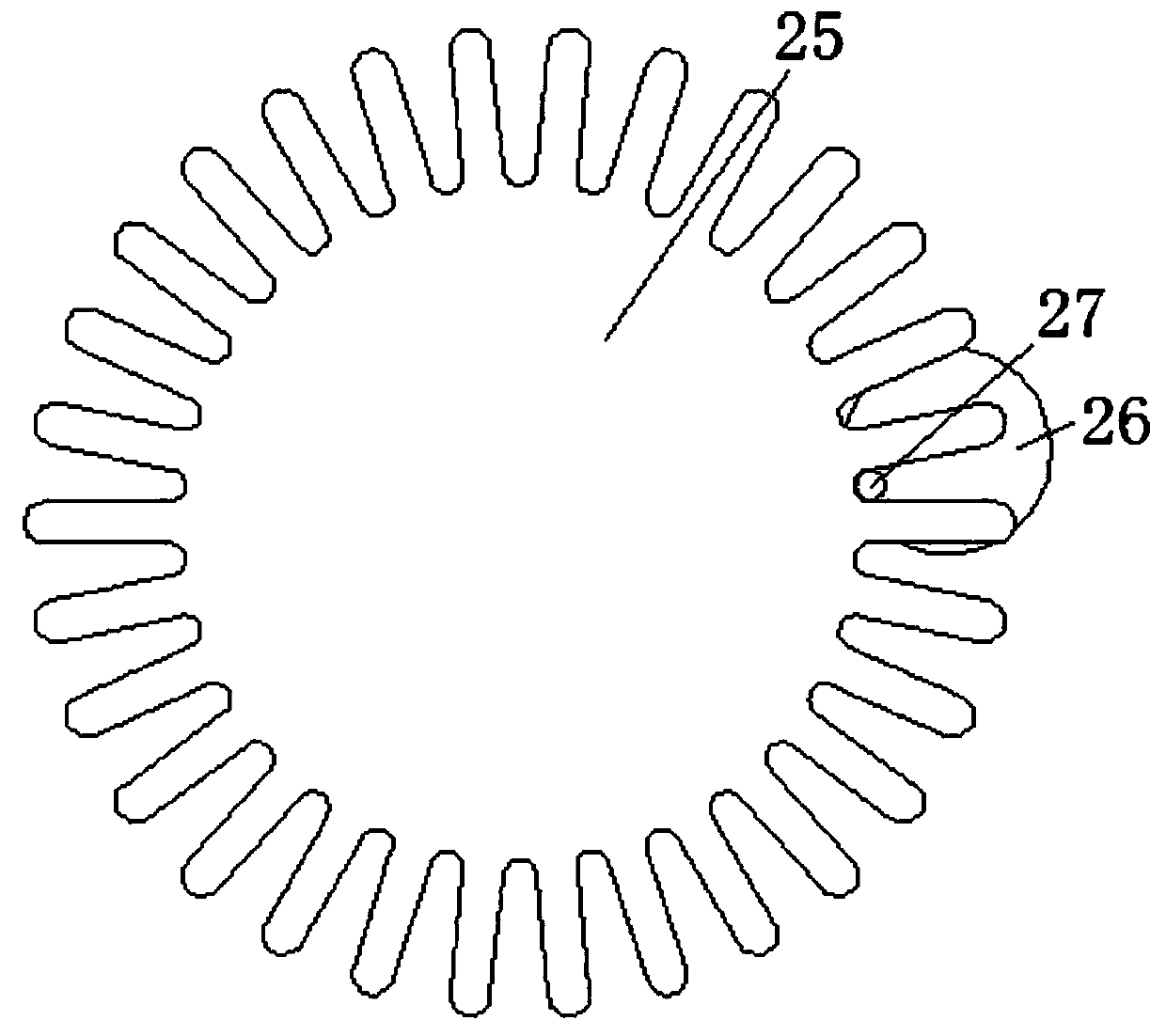

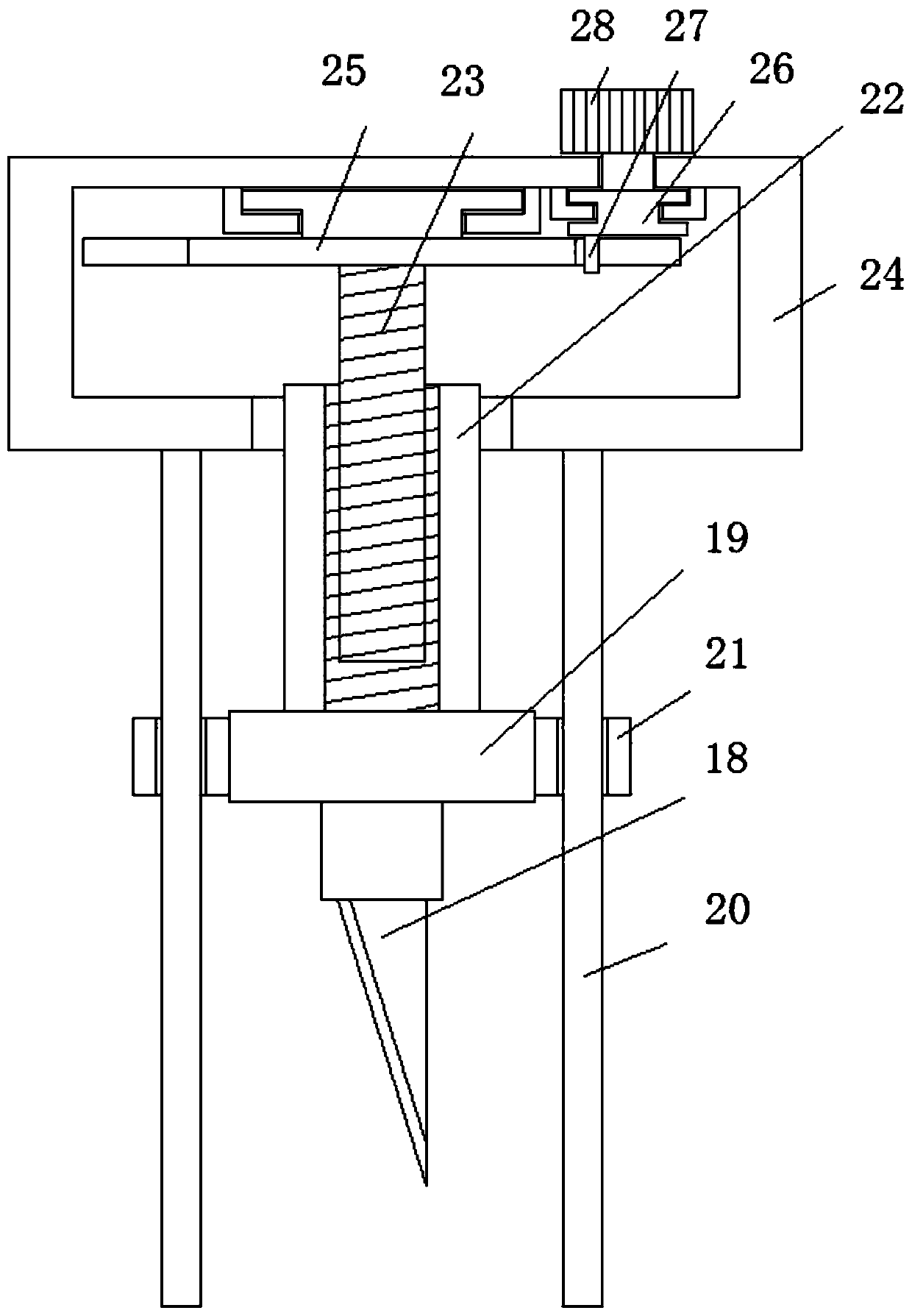

[0022] refer to Figure 1-3 , a cutting device for recycling waste cables, comprising a workbench 1, the four corners of the bottom of the workbench 1 are provided with feet 2, the top side of the workbench 1 is provided with a cable drive mechanism, and the cable drive mechanism includes a bottom roller 4 and a top roller 13. The worktable 1 is provided with a groove 1, and the inner wall of the groove 1 is fixedly connected with the horizontal shaft 3, and the bottom roller 4 is rotatably set on the outside of the horizontal shaft 3, and the top side of the workbench 1 is provided with a sliding cylinder 7. The cylinder 7 is located vertically above the groove 1. A slide rod 8 is slidably connected in the slide cylinder 7. The bottom end of the slide rod 8 extends to the bottom side of the slide cylinder 7 and is fixedly connected with a connecting plate 12. The top roller 13 is rotatably connected to the On the bottom side of the connecting plate 12, the top of the sliding ...

Embodiment 2

[0025] like Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the outer sides of the bottom roller 4 , the top roller 13 and the side rollers 16 are all covered with rubber sleeves.

[0026] In this embodiment, the frictional force is made larger to ensure the driving of the cable.

Embodiment 3

[0028] like Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1, preferably, the bottom end of the cutter 18 extends to between the two side rollers 16 .

[0029] In this embodiment, the distance between the cutter 18 and the side rollers 16 on both sides is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com