Method and device for measuring pneumatic thrust indirectly

A measurement method and thrust technology, which is applied in the field of indirect measurement of aerodynamic thrust, can solve the problems of high debugging and calibration requirements, inability to estimate measurement errors, etc., and achieve the effects of avoiding disturbance, good operability, high sampling frequency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

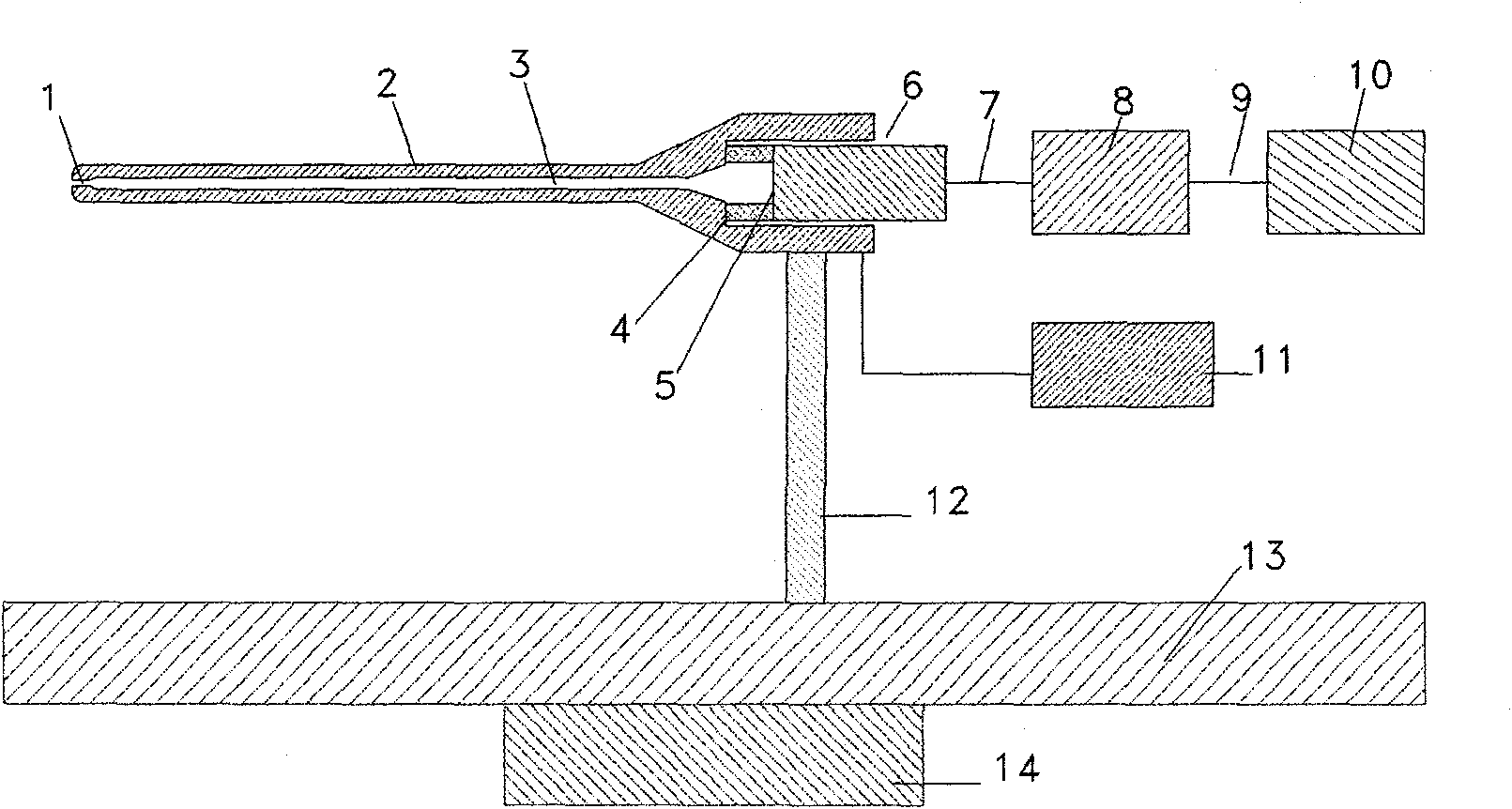

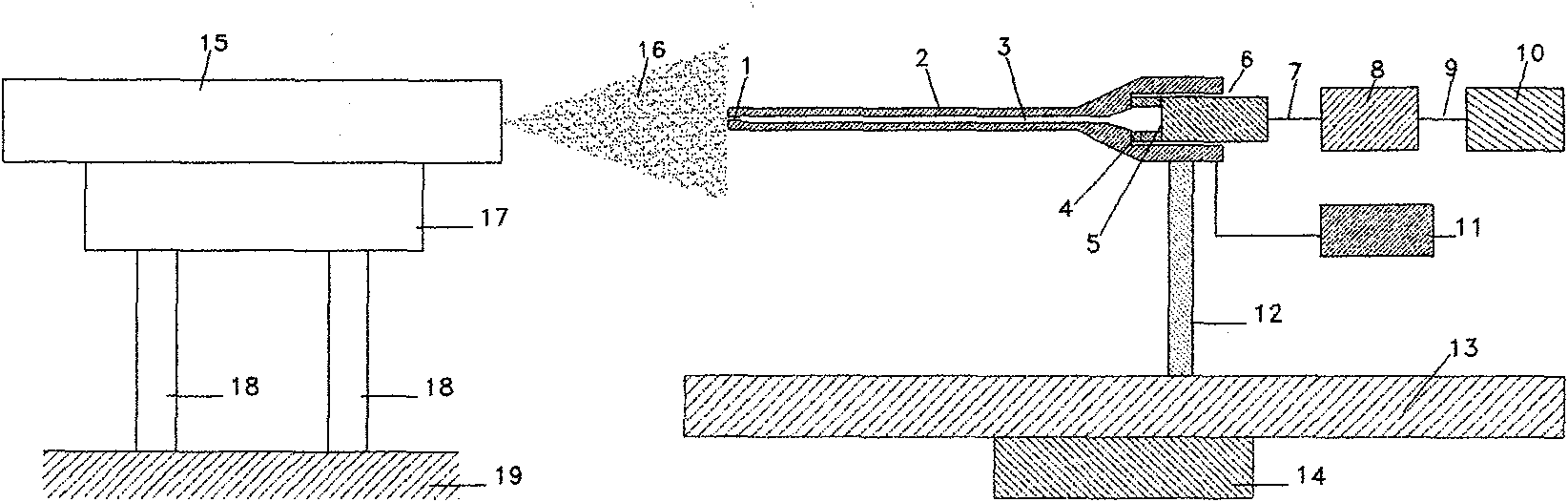

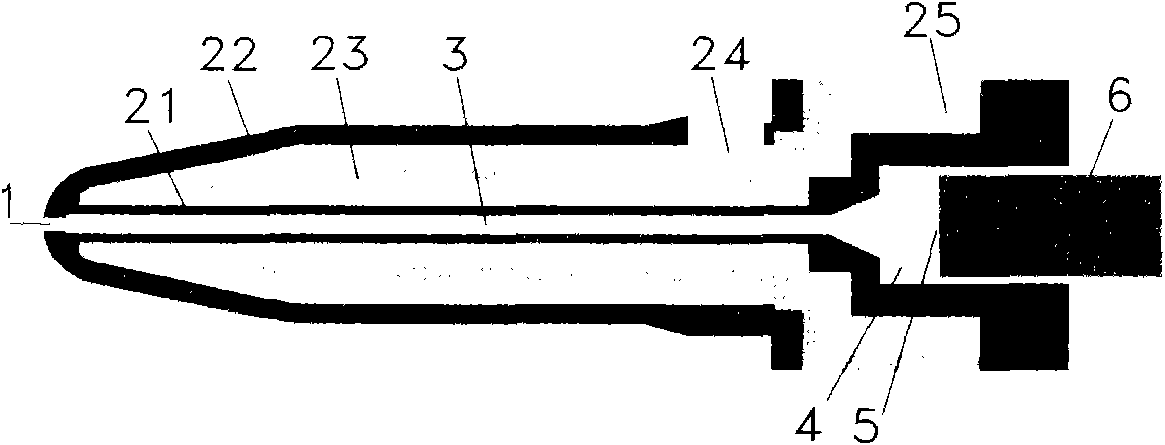

[0039] refer to figure 1 , figure 2 , making a measuring device for indirect measurement of rocket engine supersonic jet aerodynamic thrust, the device includes: 1 sampling hole, 21 water-gas isolation sleeve, 22 probe outer tube, 23 cooling water spacer, 24 cooling water outlet, 25 cooling water inlet , 3 Gas passage, 4 Insulator, 5 Differential pressure sensor sensing surface, 6 Differential pressure sensor, 7 Signal line, 8 Data acquisition system, 9 Data transmission line, 10 Data processing and analysis system, 11 Temperature adjustment system, 12 Probe support Parts, 13 movable platforms 1, 14 movable platforms 2.

[0040] In this embodiment, the diameter of the sampling hole 1 is 0.9mm, so that the measurement results can reach a higher spatial resolution; the cone angle of the conical head of the dynamic pressure probe is 24°, and the dynamic pressure probe connected to the conical head is straight The diameter of the section is 12mm to minimize the disturbance to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com