Textile cloth printing, dyeing and drying device

A technology of drying device and textile cloth, applied in drying, dryer, drying gas arrangement and other directions, can solve problems such as affecting product quality, affecting the internal environment of the box, easy fading of pigments, etc., to promote thorough drying, The effect of speeding up drying efficiency and promoting the removal of moisture from the fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

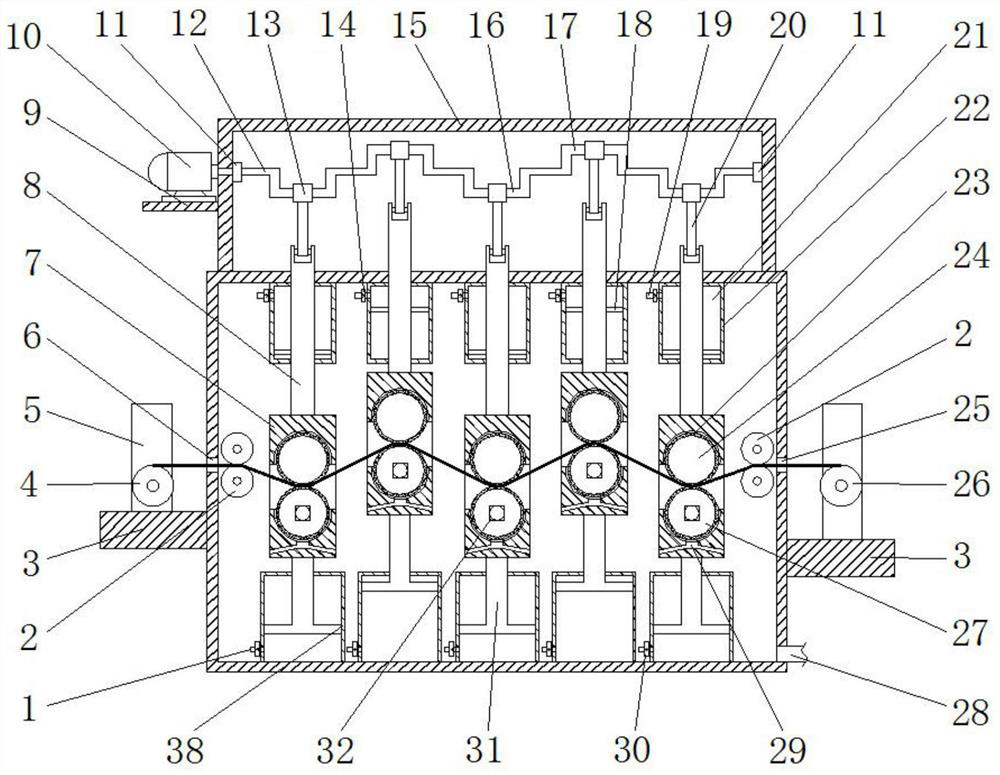

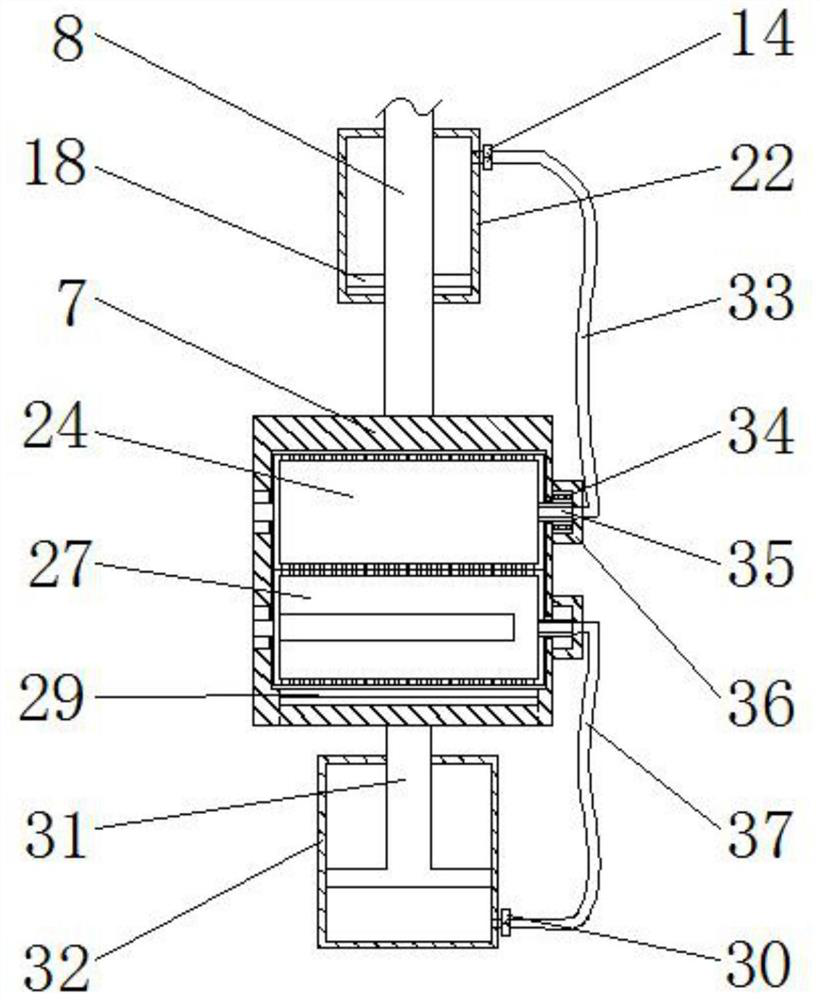

[0024] Such as figure 1A textile printing and dyeing drying device shown includes a box with an electric heating element (not shown in the figure) inside, and two opposite sides of the box are respectively provided with a cloth inlet 6 and a cloth outlet 25 aligned with each other. , the opposite sides of the cloth inlet 6 and the cloth outlet 25 are respectively provided with a set of conveying rollers 2 for conveying the cloth in the box, and at least two lifting frames 7 are arranged at equal intervals between the two sets of conveying rollers 2 ( Five lifting frames 7 are shown in the accompanying drawings), and the blowing cylinder 24 and the suction cylinder 27 for clamping cloth are provided in the lifting frame 7, and the blowing cylinder 24 and the suction cylinder 27 are both Parallel to the conveying roller group 2, and the suction cylinder 27 is located below the blowing cylinder 24, the end faces of the blowing cylinder 24 and the suction cylinder 27 are all close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com