Automatic silk screen printing machine

A technology of printing device and screen printing machine, which is applied to screen printing machines, printing machines, printing machines, etc., which can solve the problems of inconvenient adjustment of the force of the scraper, and achieve good printing effect, stable operation, and uniform moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

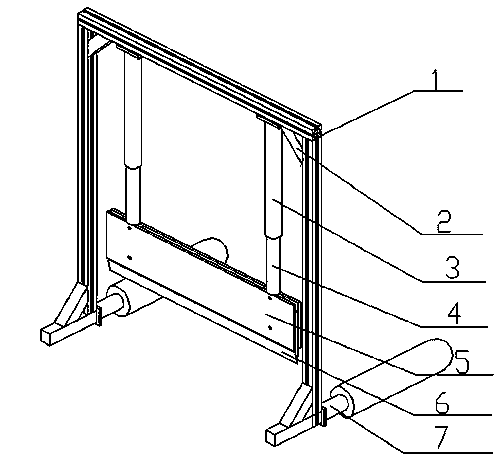

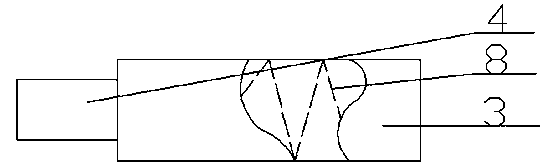

[0016] See attached figure 1 , screen printing machine printing device, including a mobile bracket 1, a coaxial sleeve outer tube 3, a coaxial sleeve inner tube 4, a scraper 6, the mobile bracket is a gantry structure perpendicular to the worktable, and the top of the mobile bracket is also set There are oblique bars, and a vertically installed cylindrical plug magnetic force cylinder is arranged below the moving support. The connecting rod is a length-adjustable connecting mechanism, the connecting rod is perpendicular to the measuring installation of the mobile bracket, the pressure of the connecting rod on the table top is adjustable, and there is a splint 5 under the connecting rod to link with the scraper 6 . By adjusting the length of the coaxial sleeve, it can adapt to the surface printing work of different heights. The pressure adjustment spring in the sleeve can adjust the pressure of the scraper on the printing surface and keep it at 50N. The entire printing mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com