Automatic sand blasting device and method for planar target material

A technology of sandblasting equipment and flat targets, which is applied in the direction of metal processing equipment, abrasive jetting machine tools, and used abrasive processing devices, etc. Low and other problems, to achieve the effect of uniform sandblasting roughness, eliminate operation hazards, and high sandblasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

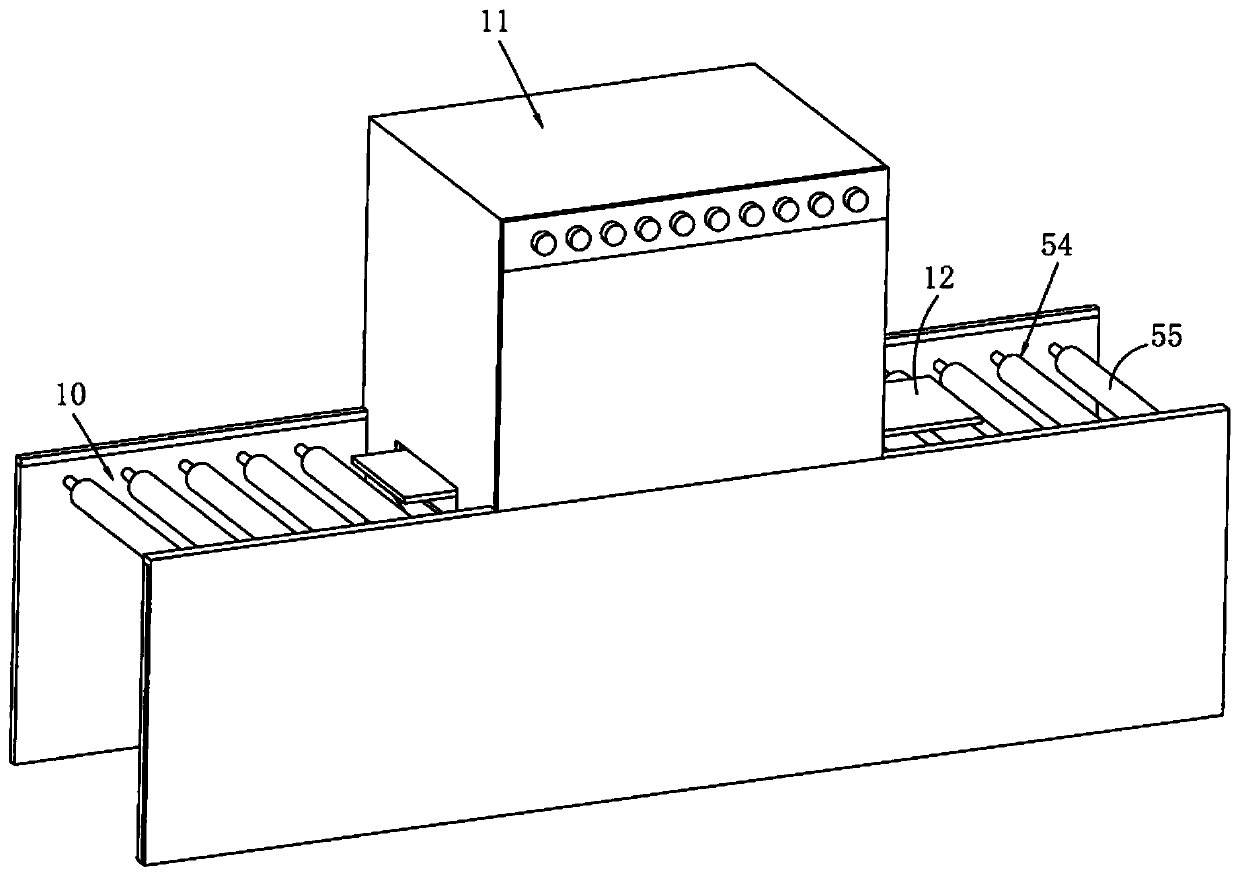

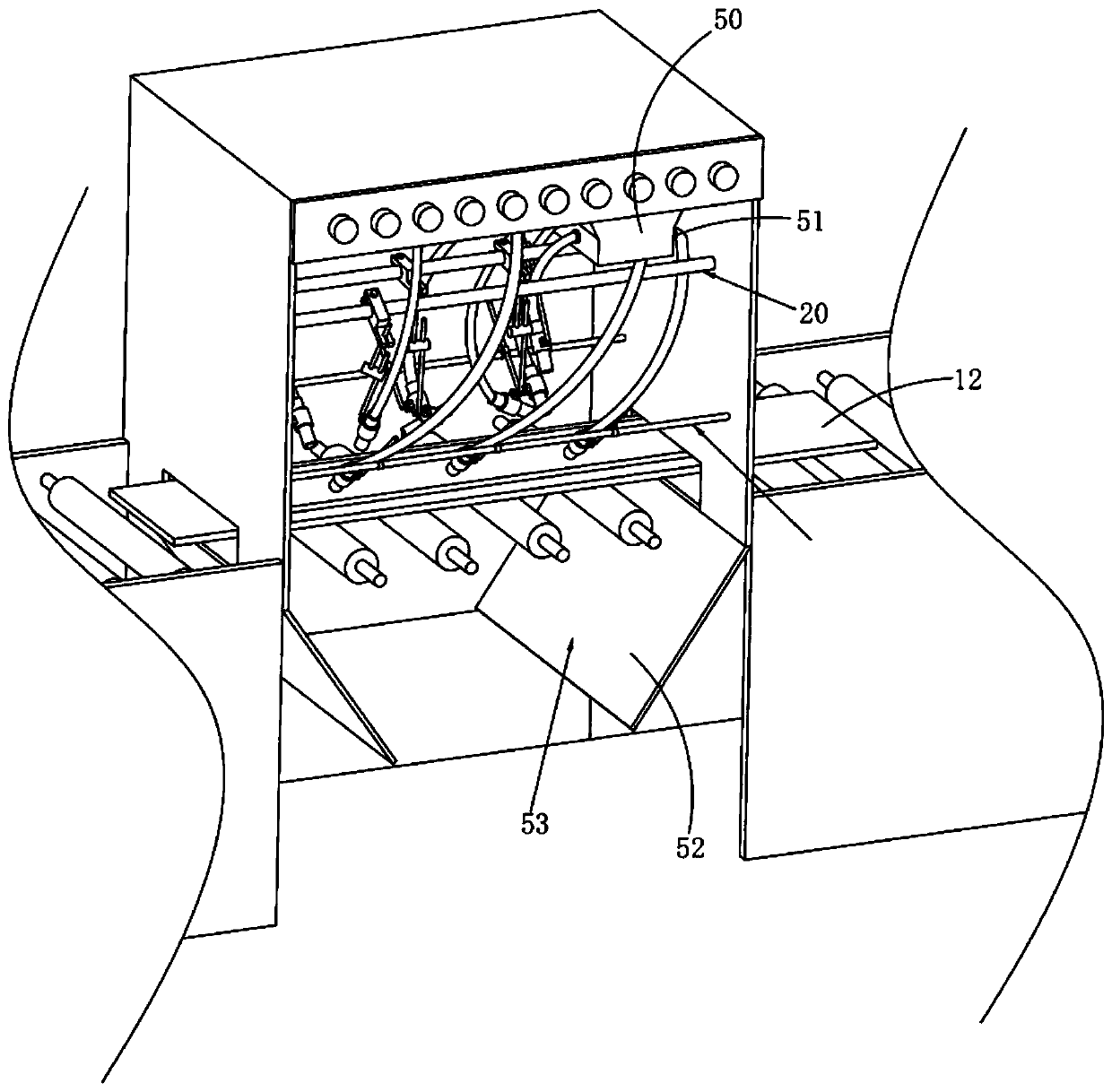

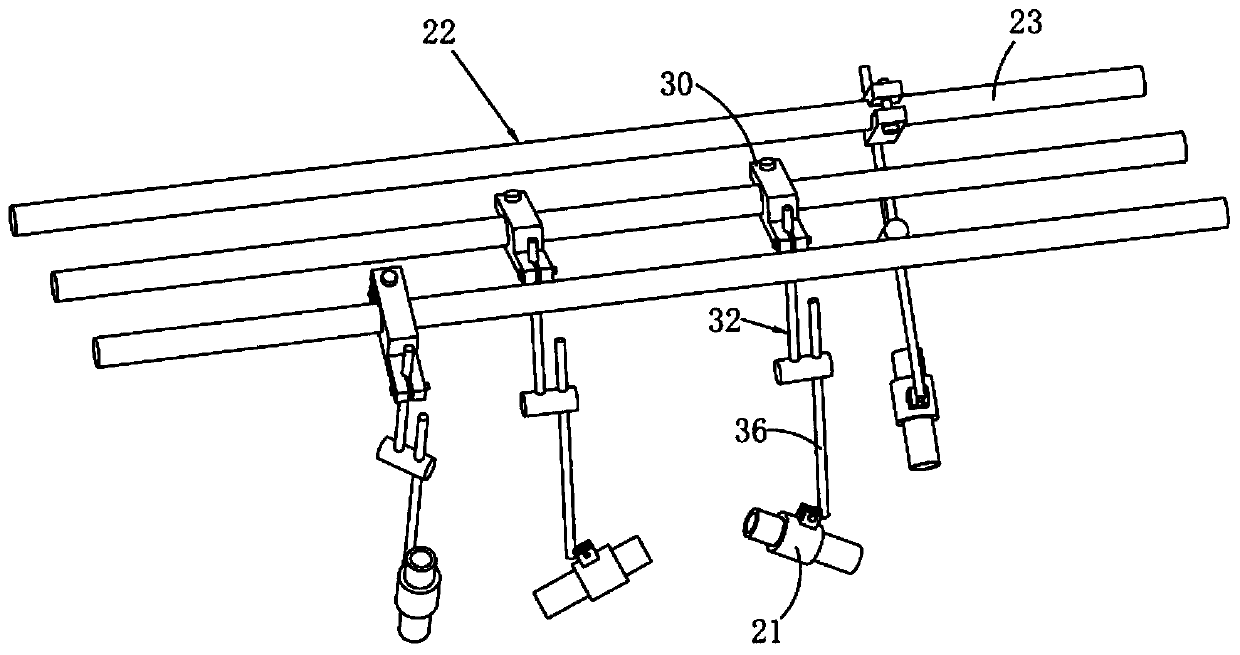

[0036] An automatic sandblasting equipment for flat targets, such as Figure 1 to Figure 8 As shown, it includes a sandblasting chamber 11 and a sandblasting platform 10. The sandblasting chamber 11 is connected to the sandblasting platform 10. The sandblasting platform 10 is provided with a transport device 54 for transporting the target material 12. The sandblasting chamber 11 is provided with a Sanding device, the sandblasting device is arranged on the top of the conveying device 54, the sandblasting device comprises a middle part sandblasting unit 20 and a side part sandblasting unit 40, the side part sandblasting unit 40 is provided with a side part sandblasting gun 41, and the side part sandblasting gun The muzzle of 41 faces the side of the target material 12, and the middle part sandblasting unit 20 is provided with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com