Steel rail corrugation laser measuring device

A laser measurement and wave-shaped technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of shortening the service life of related parts of the track and rolling stock, increasing the force of the wheel and rail, and affecting the health of residents, etc., to achieve measurement The data is accurate and reliable, the step size is constant, and the detection is convenient and fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

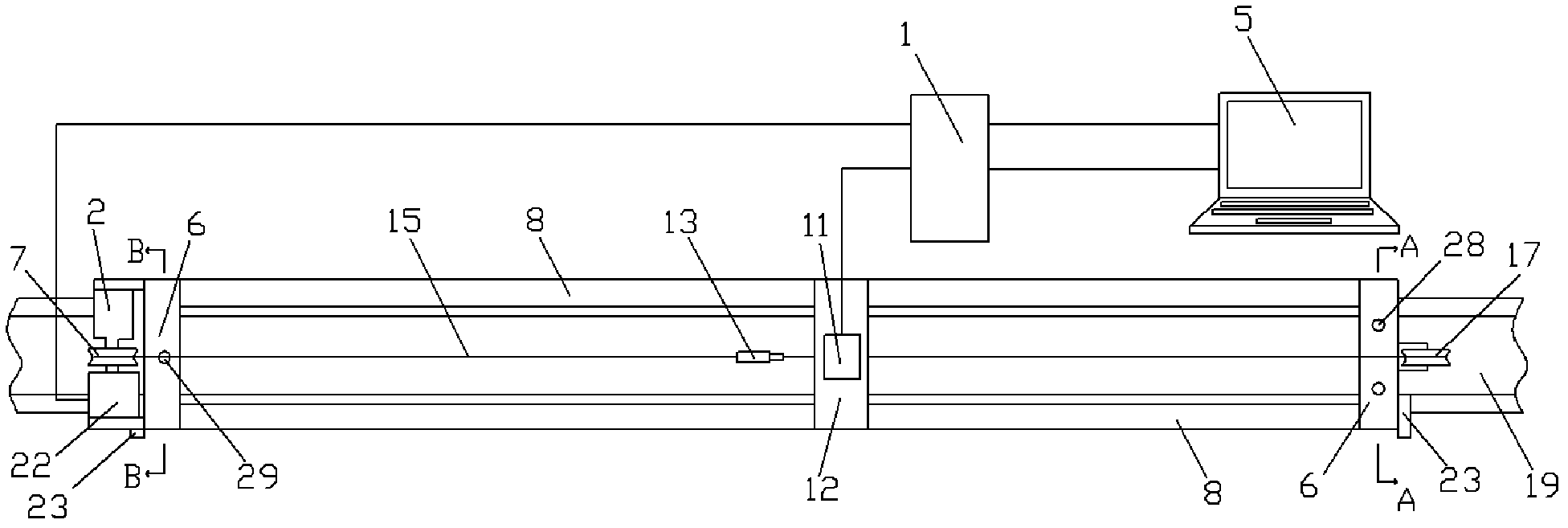

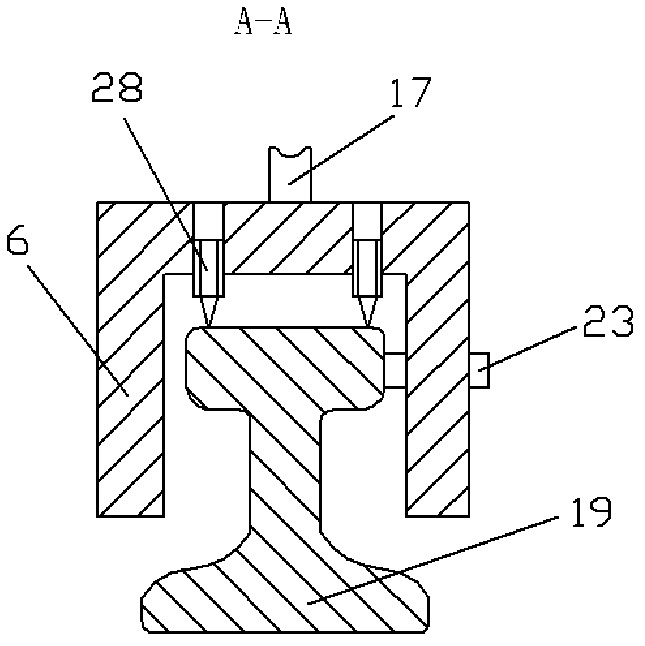

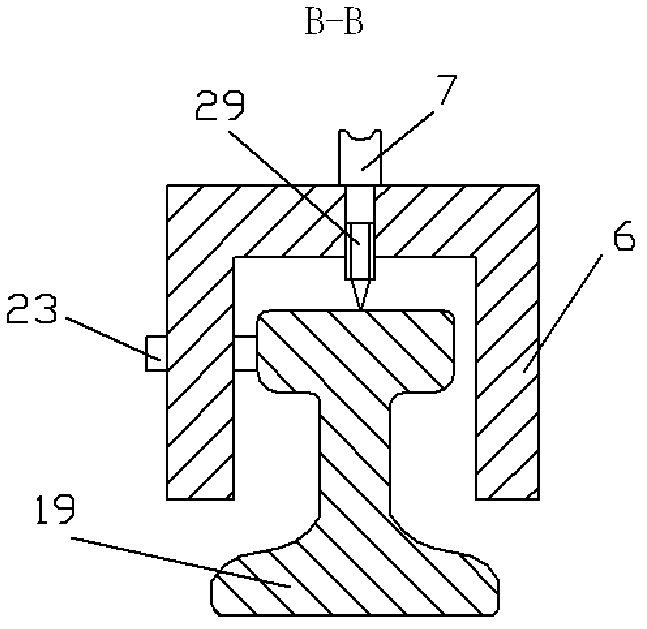

[0028] Figure 1-3 As shown, a specific embodiment of the present invention is: a rail wave wear laser measuring device, which is composed of:

[0029] Both ends of the device have a bracket 6 that can be placed on the rail 19. Guide rails 8 are fixed on both sides of the top of the bracket 6, and a slider 12 is fitted on the guide rail 8; the laser head 11 of the laser displacement sensor 1 is fixed on the slider 12. Above, the serial port and the USB interface of the laser displacement sensor 1 are connected to the serial port and the USB interface of the computer 5 respectively;

[0030] Motor 2 is fixed on the bracket 6 at one end, fixed pulley 1 7 is connected on the shaft of motor 2, fixed pulley 2 17 is installed on the bracket 6 of the other end; Pass fixed pulley 1 7, fixed pulley 2 17 and then be connected with slide block 12; The shaft end of motor 2 is connected with incremental photoelectric encoder 22, the signal output end of this incremental photoelectric enco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com