Production machining equipment of color steel tiles

A technology of processing equipment and color steel tiles, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems that the quality and consistency of processing are difficult to guarantee, the processing pressure cannot be controlled, and the safety performance of use needs to be improved. , to achieve the effect of improving safety performance, novel structure and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

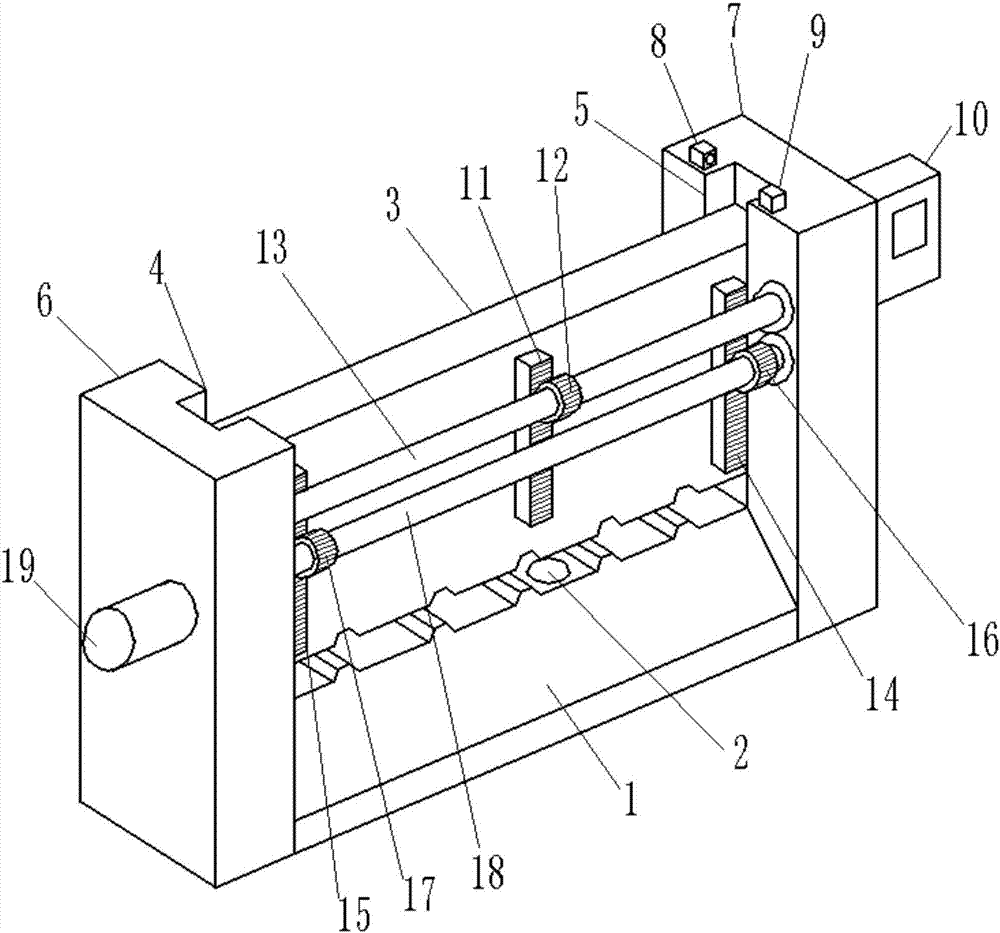

[0017] see figure 1 , in an embodiment of the present invention, a color steel tile production and processing equipment, including a base 1, a pressure sensor 2, a movable platen 3, a left chute 4, a right chute 5, a left bracket 6, a right bracket 7, and a laser emitter 8 , laser receiver 9, control module 10, driven rack 11, driven wheel 12, driven shaft 13, right drive rack 14, left drive rack 15, right drive wheel 16, left drive wheel 17, drive shaft 18 and a motor 19, a pressure sensor 2 is installed in the middle of the upper end surface of the base 1, a movable platen 3 is arranged above the base 1, the left end surface of the movable platen 3 is slidably connected with the left chute 4, and the right end surface of the movable platen 3 Slidingly connected with the right chute 5, the left chute 4 is arranged on the middle part of the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com