Numerical control machine tool guide rail molded surface rapid detection device and method

A detection device and a technology of numerically controlled machine tools, which are applied to measurement devices, optical devices, instruments, etc., can solve the problems of large measurement distance, difficulty in measuring straightness, and difficulty in achieving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The patent will be further described below in conjunction with the accompanying drawings.

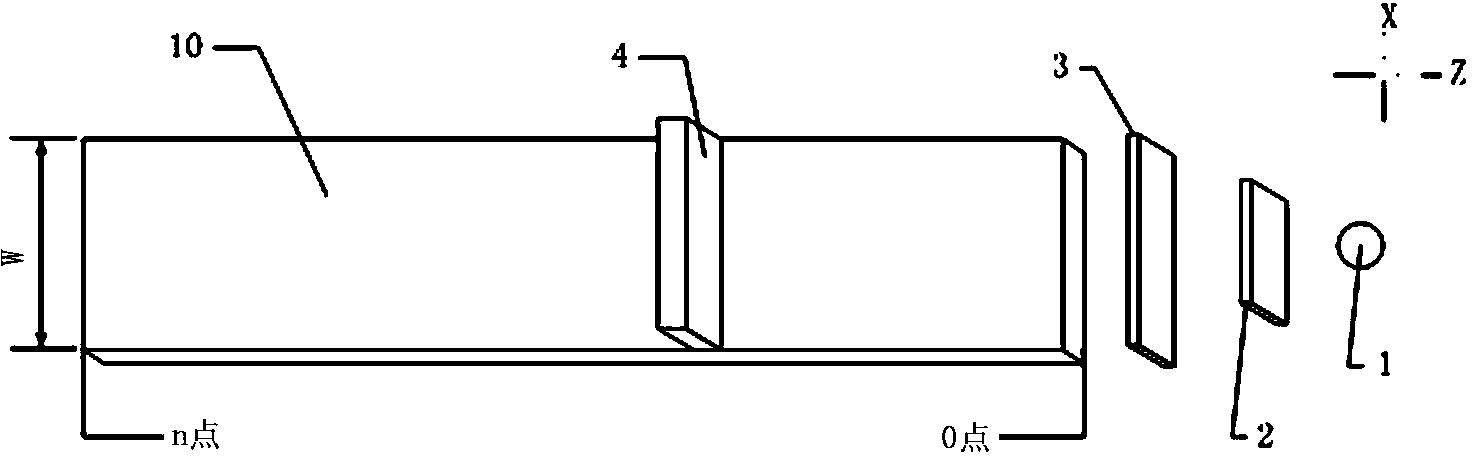

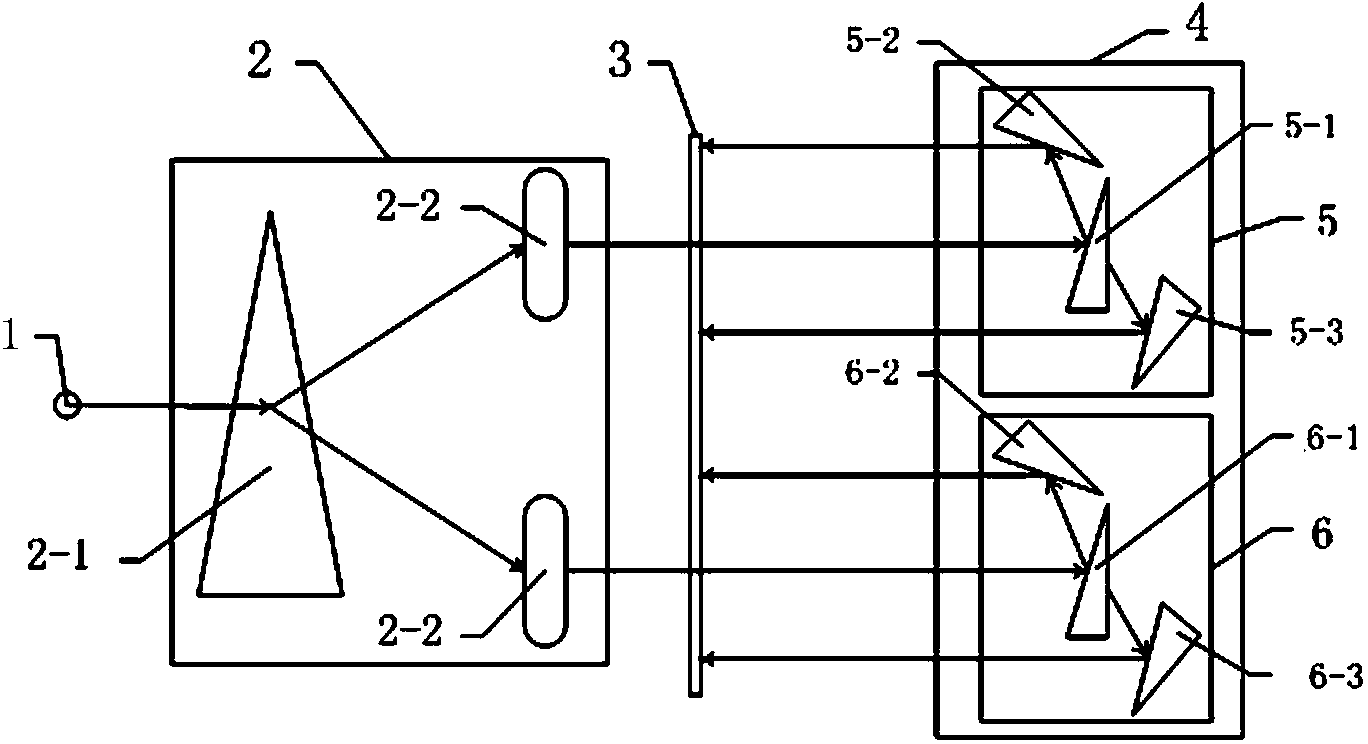

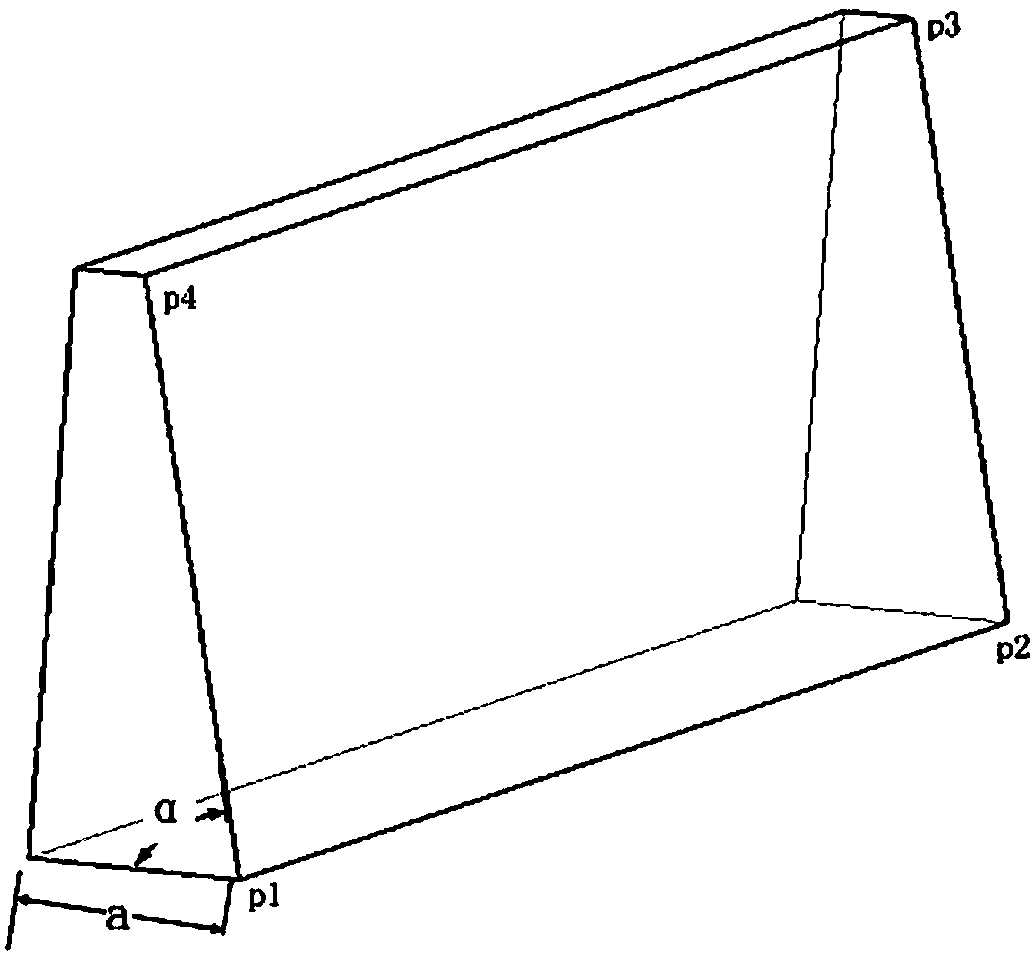

[0028] like figure 1 and figure 2 As shown, the rapid detection device for the guide rail profile of the CNC machine tool of this patent is composed of a laser emitter (1), a beam splitter (2), an optical component (4) movable on the guide rail and a laser receiver (3 )composition. The beam splitter 2 is composed of a Wollaston prism (2-1) and two objective lenses (2-2), and divides the laser light emitted by the laser transmitter into two beams of parallel light; the two beams of parallel light enter the optical beam in the optical component (4) respectively. In the lens group I (5) and the optical lens group II (6), each optical lens group divides the input light source of the laser into a refracted light and a reflected light and reflects them to the laser receiver (3) through the reflector.

[0029] The optical lens group (5) can test the movement deviation along the X ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com