A continuous pad printing coding method

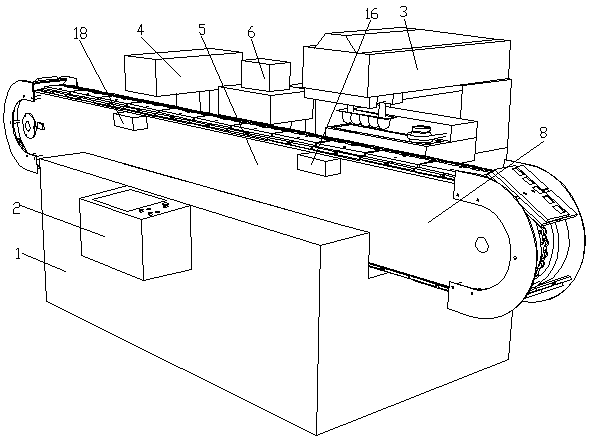

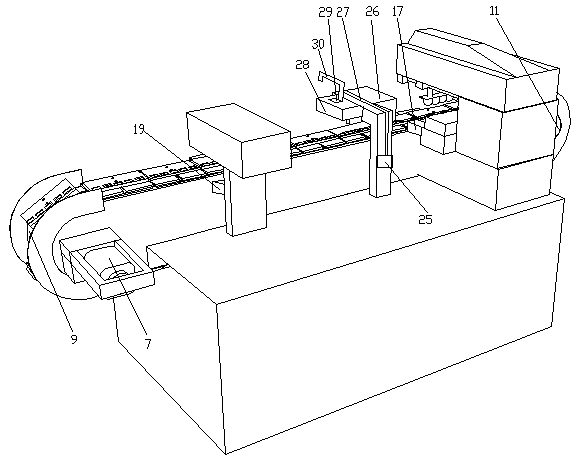

A pad printing and pad printing machine technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of difficult large-volume, continuous pad printing, easy fading of ink, low pad printing efficiency, etc., to achieve Accurate coding, good drying effect, increase the effect of scraping ink step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

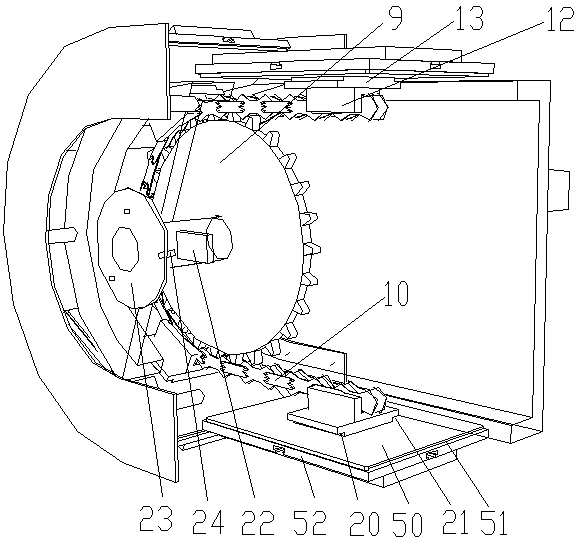

[0047] A continuous pad printing coding method, comprising the following steps:

[0048] a. Ink the etched plate 34 through the sealed oil cup 35 of the pad printing coding device to form patterned ink;

[0049] b. Push the rubber head 32 of the pad printing machine 3 forward to the top of the etching plate 34, then drive the rubber head 32 down to contact the etching plate 34, press the rubber head 32 to dip the ink with the pattern, and then drive the rubber head 32 rise and return to the original position;

[0050] c. Push the rubber head 32 backward to the pad printing station of the conveying part 5, and then drive the rubber head 32 to press down, and the rubber head 32 will print the ink with the pattern on the printed item in the mold groove 15 ;

[0051] d. Move the printed article after pad printing to the drying station through the conveying part 5, heat the printed article after pad printing through the resistance heating wire 27 of the drying part 6, and then pa...

Embodiment 2

[0055] A continuous pad printing coding method, comprising the following steps:

[0056] a. Ink the etched plate 34 through the sealed oil cup 35 of the pad printing coding device to form patterned ink;

[0057] b. Push the rubber head 32 of the pad printing machine 3 forward to the top of the etching plate 34, then drive the rubber head 32 down to contact the etching plate 34, press the rubber head 32 to dip the ink with the pattern, and then drive the rubber head 32 rise and return to the original position;

[0058] c. Push the rubber head 32 backward to the pad printing station of the conveying part 5, and then drive the rubber head 32 to press down, and the rubber head 32 will print the ink with the pattern on the printed item in the mold groove 15 ;

[0059] d. Move the printed article after pad printing to the drying station through the conveying part 5, heat the printed article after pad printing through the resistance heating wire 27 of the drying part 6, and then pa...

Embodiment 3

[0066] A continuous pad printing coding method, comprising the following steps:

[0067] a. Ink the etched plate 34 through the sealed oil cup 35 of the pad printing coding device to form ink with patterns;

[0068] b. Push the rubber head 32 of the pad printing machine 3 forward to the top of the etching plate 34, then drive the rubber head 32 down to contact the etching plate 34, press the rubber head 32 to dip the ink with the pattern, and then drive the rubber head 32 rise and return to the original position;

[0069] c. Push the rubber head 32 backward to the pad printing station of the conveying part 5, and then drive the rubber head 32 to press down, and the rubber head 32 will print the ink with the pattern on the printed item in the mold groove 15 ;

[0070] d. Move the printed article after pad printing to the drying station through the conveying part 5, heat the printed article after pad printing through the resistance heating wire 27 of the drying part 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com