A uv ultraviolet laser inkjet printer for intelligent manufacturing

An ultraviolet laser, intelligent manufacturing technology, applied in manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve the problems of data and actual data inconsistency, product delivery, etc., to avoid false spray and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

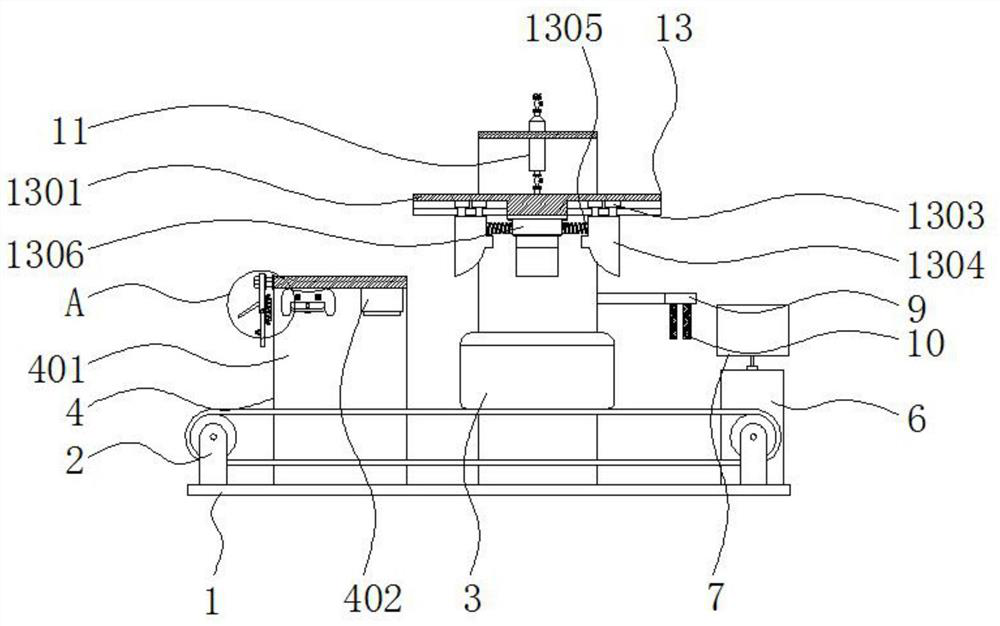

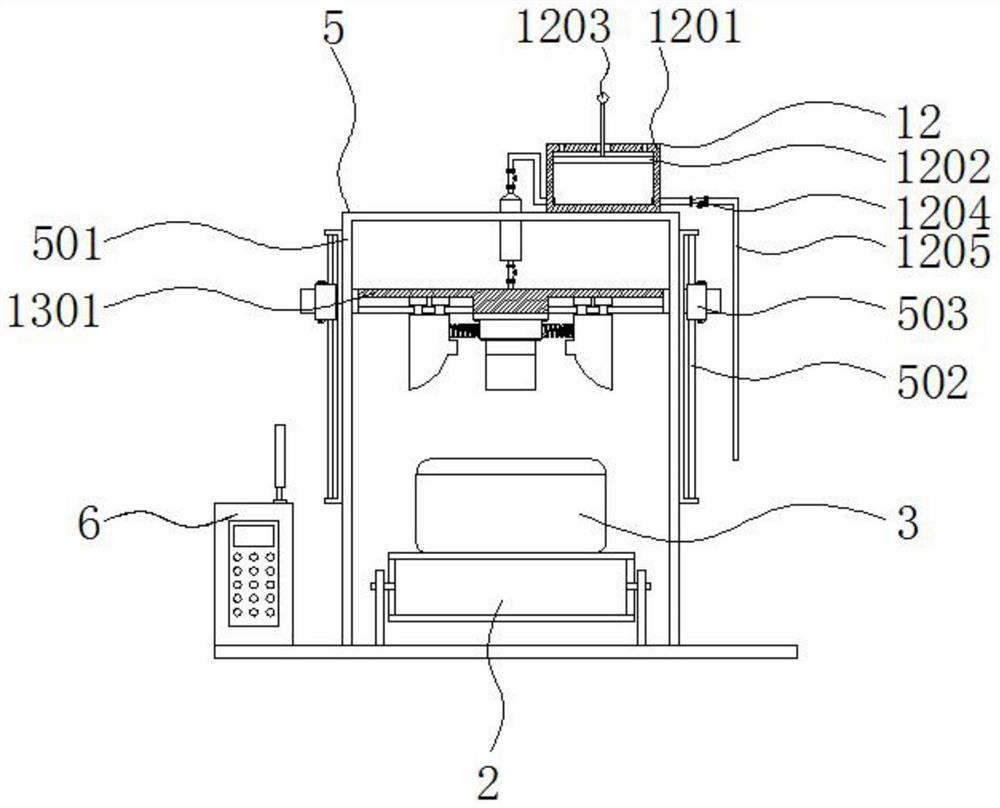

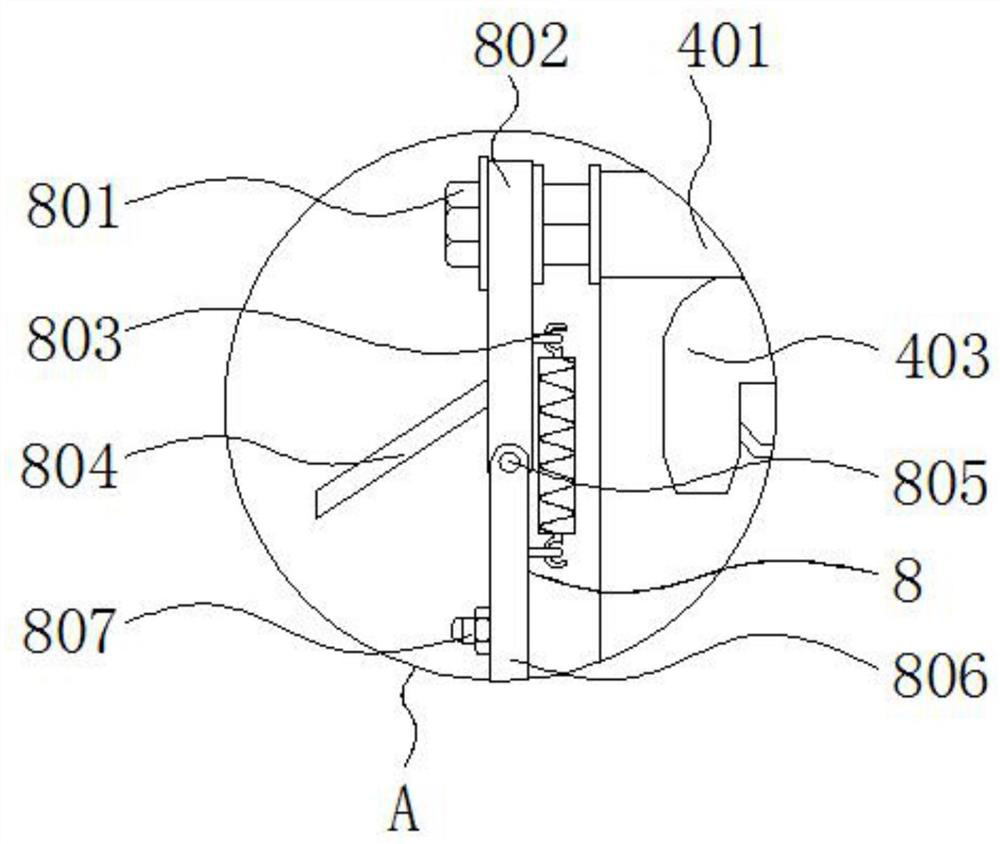

[0028] Such as Figure 1 to Figure 5 As shown, the present invention provides a technical solution: a UV ultraviolet laser inkjet printer for intelligent manufacturing, including a base 1 and a dry detection assembly 4, and the upper end of the base 1 is sequentially provided with a dry detection assembly 4, a support lift Component 5 and operating table 6, and display screen 7 is placed on the upper end of operating table 6, drying detection assembly 4 comprises fixed frame 401, ultraviolet laser curing device 402 and scanner 403, and the upper wall lower side of fixed frame 401 is from right to An ultraviolet laser curing device 402 and a scanner 403 are installed in turn on the left, and a counting mechanism 8 is installed on the left side of the drying detection component 4;

[0029] The specific operation is as follows, the lifting assembly 5 is supported, and the positioning and coding assembly 13 can be controlled to lift. The console 6 and the display screen 7 can cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com