Large-span code spraying machine

A technology of inkjet printer and large span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

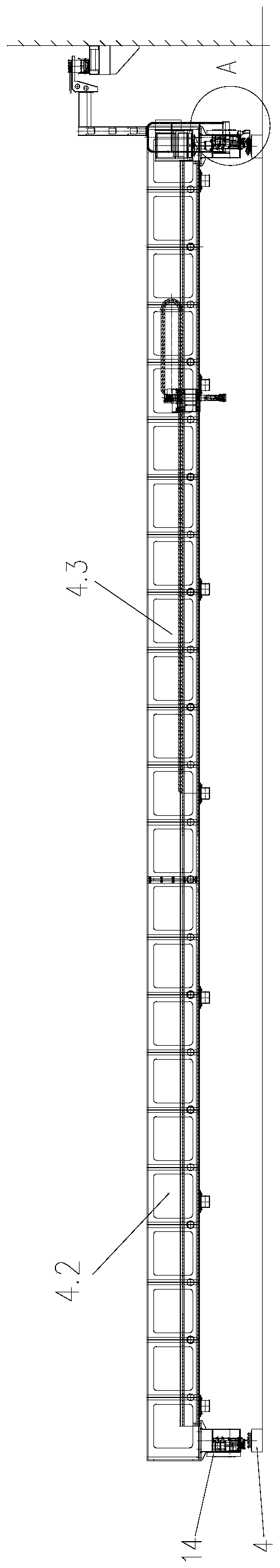

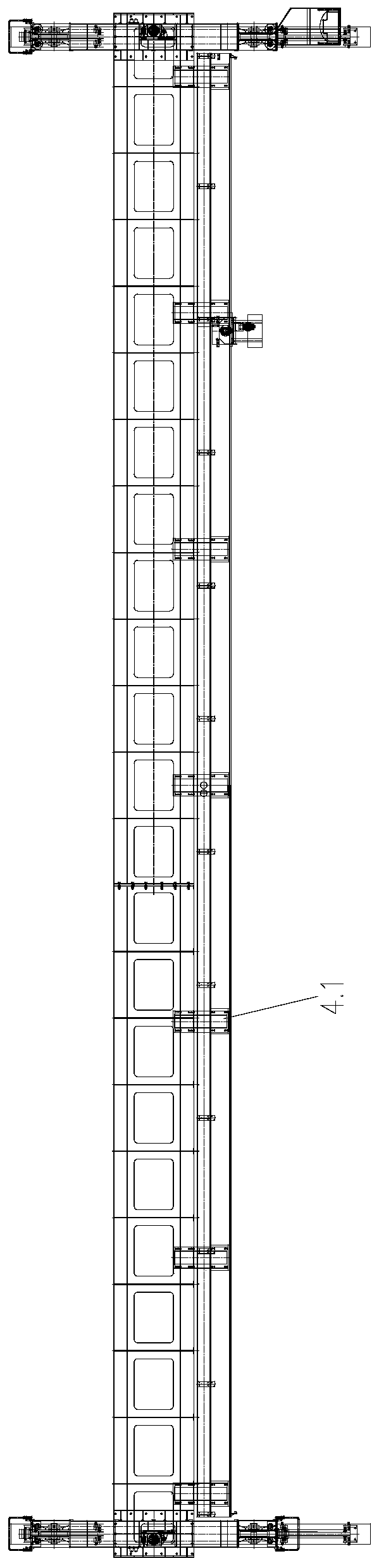

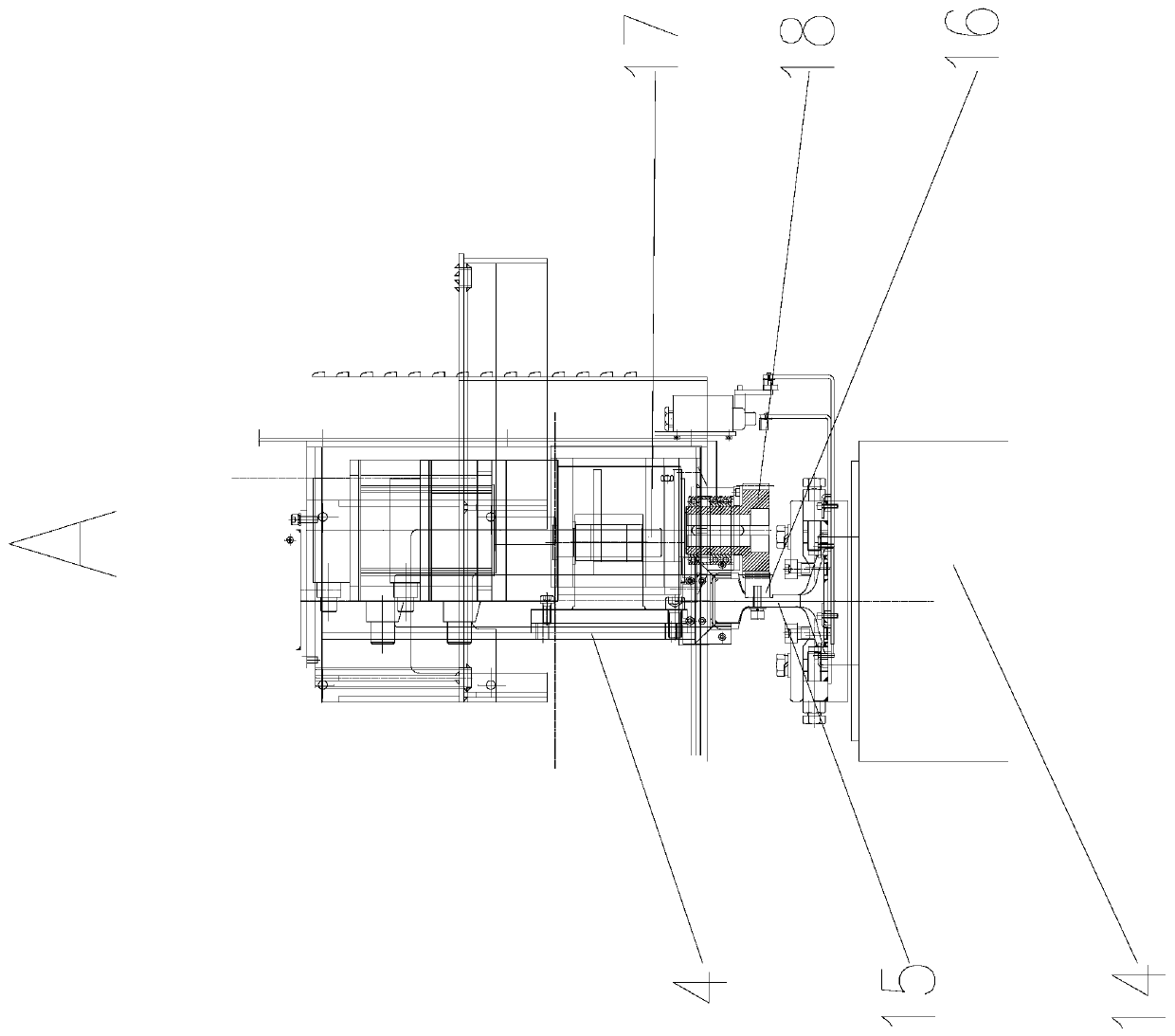

[0022] Figure 1-6 Among them, including jetting dock clamp block 1, jetting dock placement hole 1-1, elastic adjustment slot 1-2, locking screw hole 1-3, driving slide plate 3, supporting frame 4, adjusting bracket 4.1, left beam 4.2 , right beam 4.3, left front beam 4.4, right front beam 4.5, linear guide rail 4.9, transverse rack 4.10, lifting device 5, base 14, moving guide rail 15, moving rack 16, moving motor 17, moving gear 18, lateral moving motor 19 , Lateral movement gear 20 etc.

[0023] like Figure 1-4 As shown, the present invention is a large-span inkjet printer, including a base 14, the base 14 is H-shaped steel, which is convenient for manufacture. Base 14 is symmetrically arranged, and horizontally set moving guide rail 15 on base 14, and moving rack 16 is set on moving guide rail 15 sides, moves on moving guide rail 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com