A printing control method for a printing system

A control method and printing technology, applied in printing, printing devices, typewriters, etc., can solve the problem of large printing errors, and achieve the effects of accurate coding, effective control, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

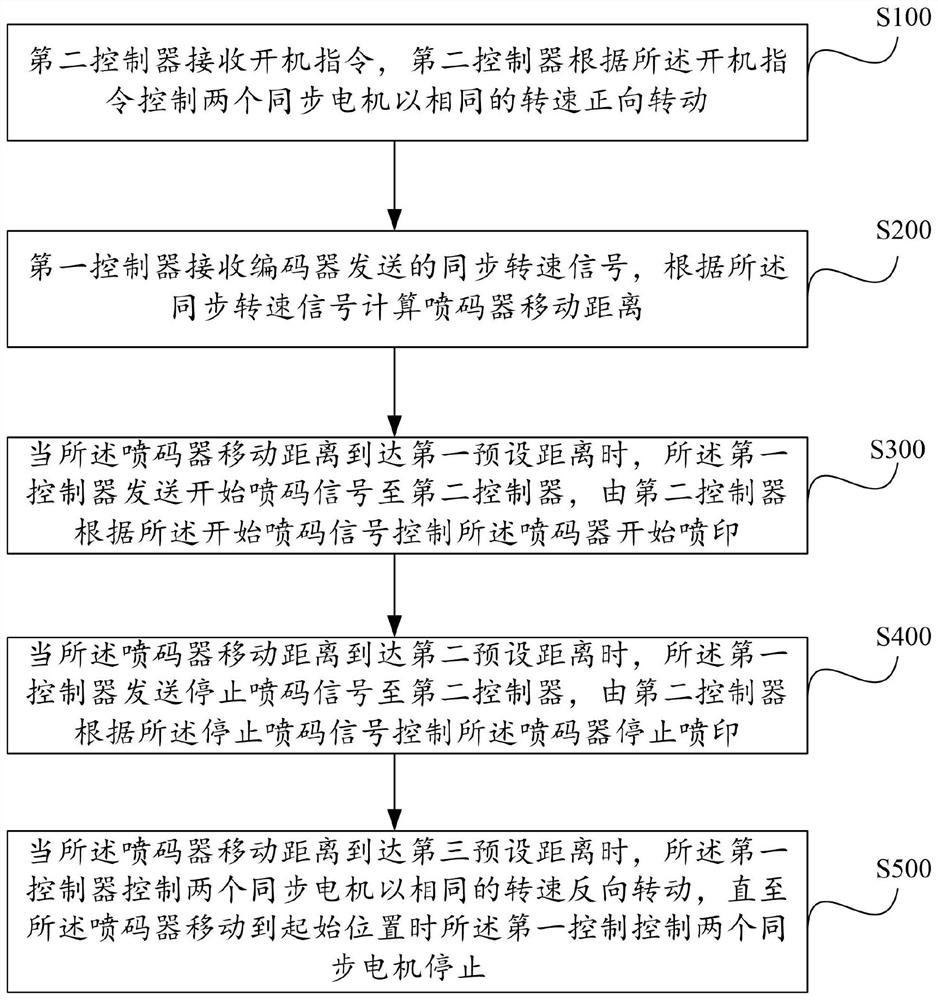

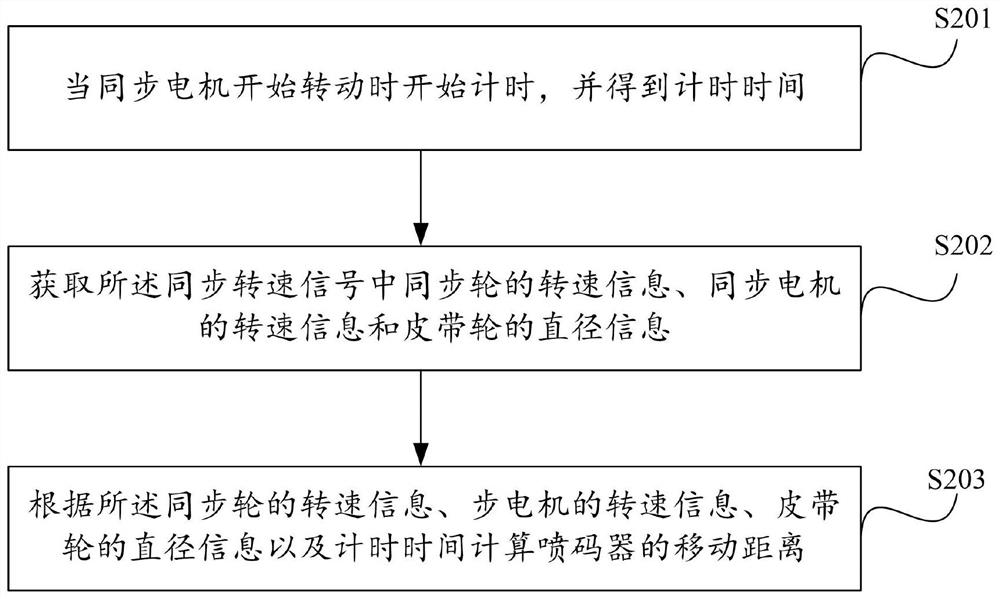

[0052] Based on the above description of the jet printing system, this embodiment provides a jet printing control method, and the jet printing control method is applied to the above jet printing system.

[0053] like figure 1 As shown, a spray printing control method provided by an embodiment of the present invention includes the following steps:

[0054] In step S100, the second controller receives the power-on command, and the second controller controls the two synchronous motors to rotate in the forward direction at the same speed according to the power-on command, the synchronous motor drives the belt to move forward, and the belt drives the inkjet printer Move forward along the rail.

[0055] In a specific implementation process, the power-on command may be a manual switch to turn on the power-on, so as to control the second controller to work, which is used as the power-on command. In this embodiment, the direction in which the code starts to move is designated as the ...

Embodiment 2

[0074] Based on the printing control method of the above-mentioned embodiment, in the specific implementation process, the phenomenon of slippage may occur between the belt and the pulley, and the detection signal of the first controller includes the speed information of the encoder synchronous pulley. The speed information of the synchronous pulley indicates the speed of the belt. The first controller compares the speed information of the synchronous pulley and the speed information of the two synchronous motors to see if they match. If they do not match, it means that there is slippage between the belt and the synchronous pulley. , the first controller sends a signal for adjusting the rotational speed to the second controller, and the second controller controls and adjusts the rotational speed of the two synchronous motors according to the signal.

Embodiment 3

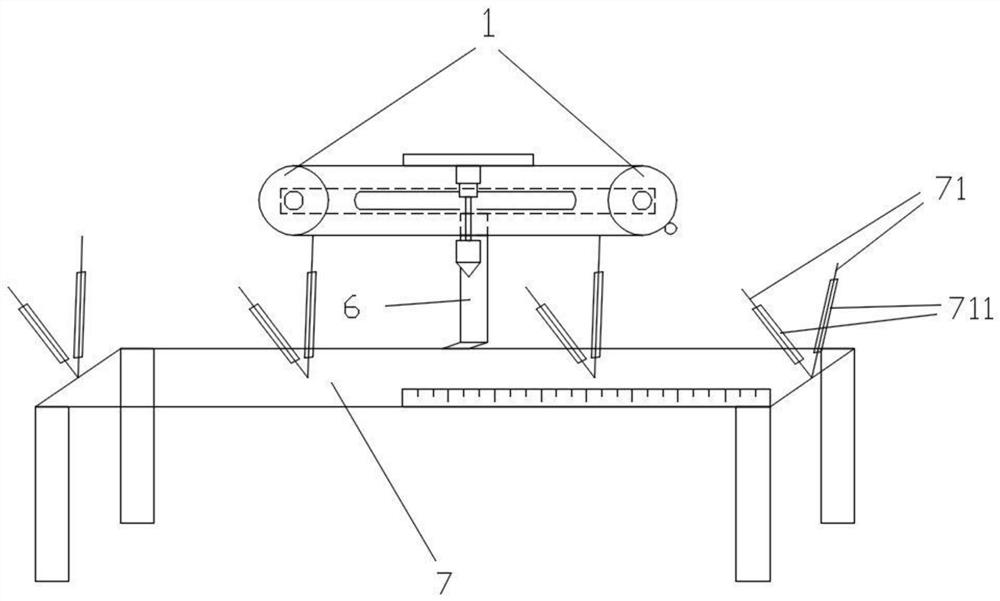

[0076] Based on the above embodiment, when printing is not started, it is necessary to detect whether the pipe material to be sprayed reaches the designated printing area and whether it is facing the printer, and then the first controller sends a power-on command to the second controller to avoid the occurrence of In the case where the spray pipe starts to print before it reaches the print area, this embodiment provides the following two detection methods:

[0077] The printing system also includes a photoelectric switch receiver. Specifically, photoelectric switch receivers are installed at both ends of the guide rail, and photoelectric switch transmitters corresponding to the receivers are installed on the workbench. The two photoelectric switch receivers are electrically connected to the first controller. connect.

[0078] Applied to this jet printing system, a detection method of the jet printing control method provided by this embodiment includes:

[0079] The first cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com