A parallel type three-axis linear robot

A robot and parallel technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of short working stroke, long branch link mechanism, insufficient motion stability, etc., and achieve increased working stroke and large working stroke. , space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

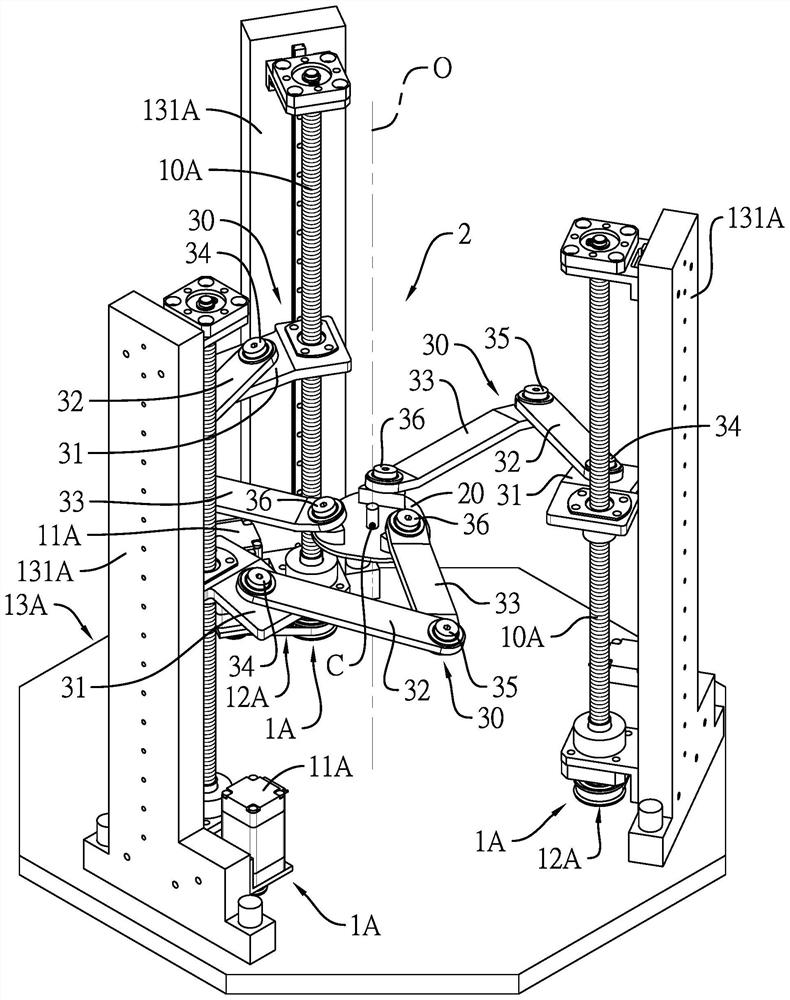

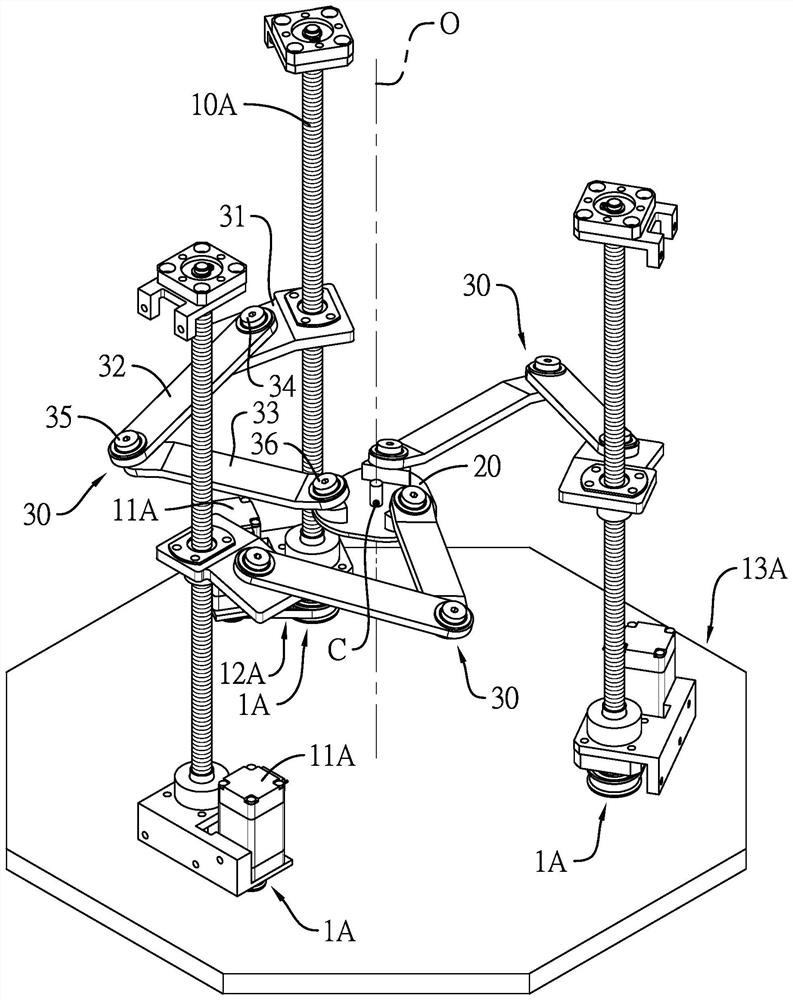

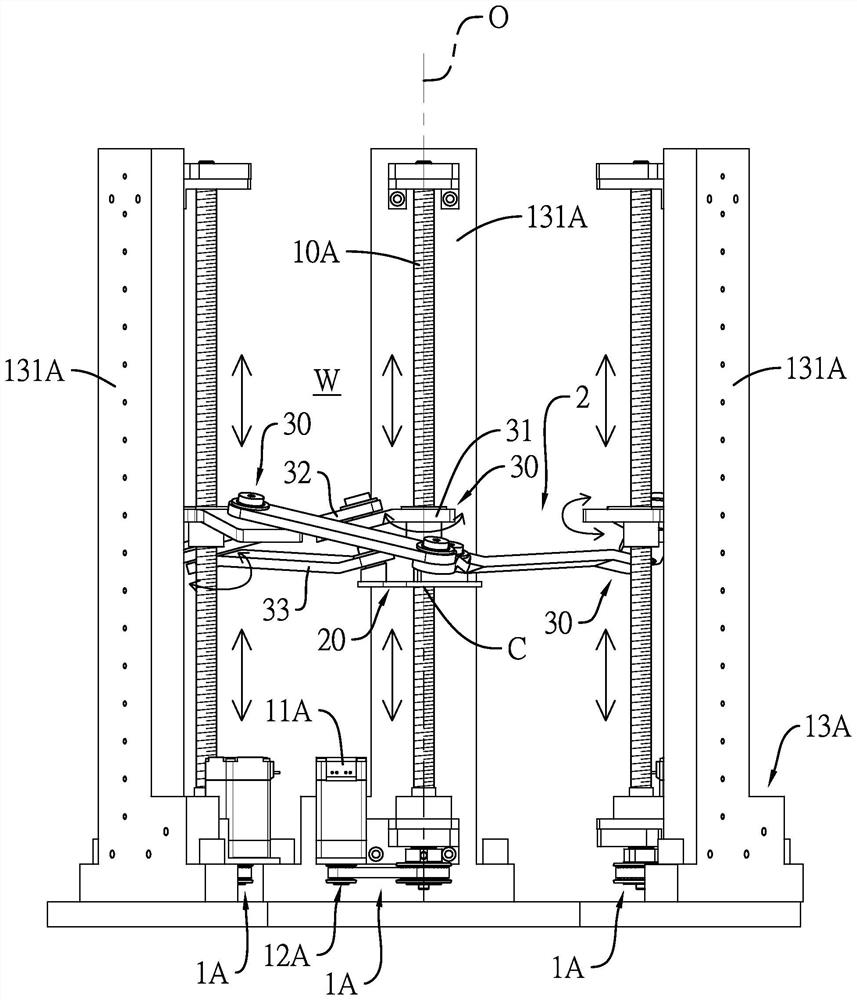

[0091] like figure 1 , Figure 5 and Figure 10 As shown, it discloses three preferred embodiments of the parallel three-axis linear robot of the present invention. As can be seen from these drawings, the parallel three-axis linear robot defines a workspace W (workspace) and through the work A central axis O of the geometric center of the section W includes three drivers 1A, 1B, 1C and a motion mechanism 2 .

[0092] like figure 1 , Figure 5 and Figure 10 As shown, the three drivers 1A, 1B, and 1C are distributed and disposed on the periphery of the central axis O, and the three drivers 1A, 1B, and 1C input driving forces in a linear or rotational manner. The three drivers 1A, 1B, 1C can at least figure 1 , Figure 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com