Device, system and method for realizing precise code tagging of top covers of zip-top cans

A technology of pop-top cans and top lids, applied in printing, laser welding equipment, typewriters, etc., can solve problems such as corrosion resistance and damage to protective coatings, and achieve the effect of avoiding contact and ensuring food safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

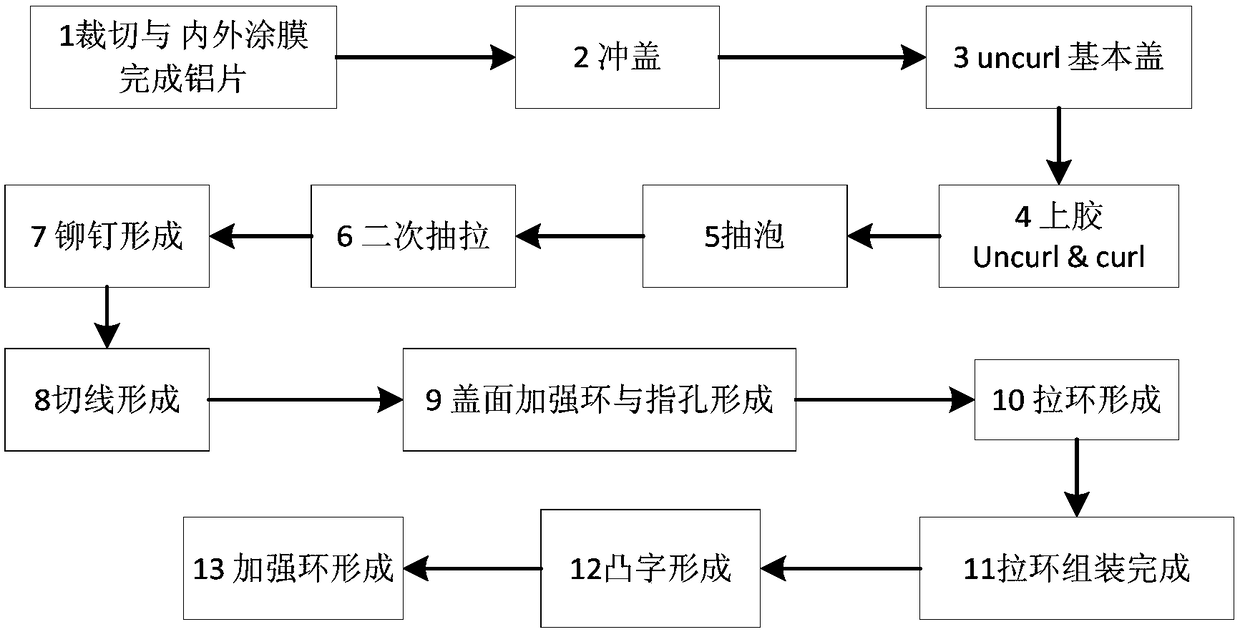

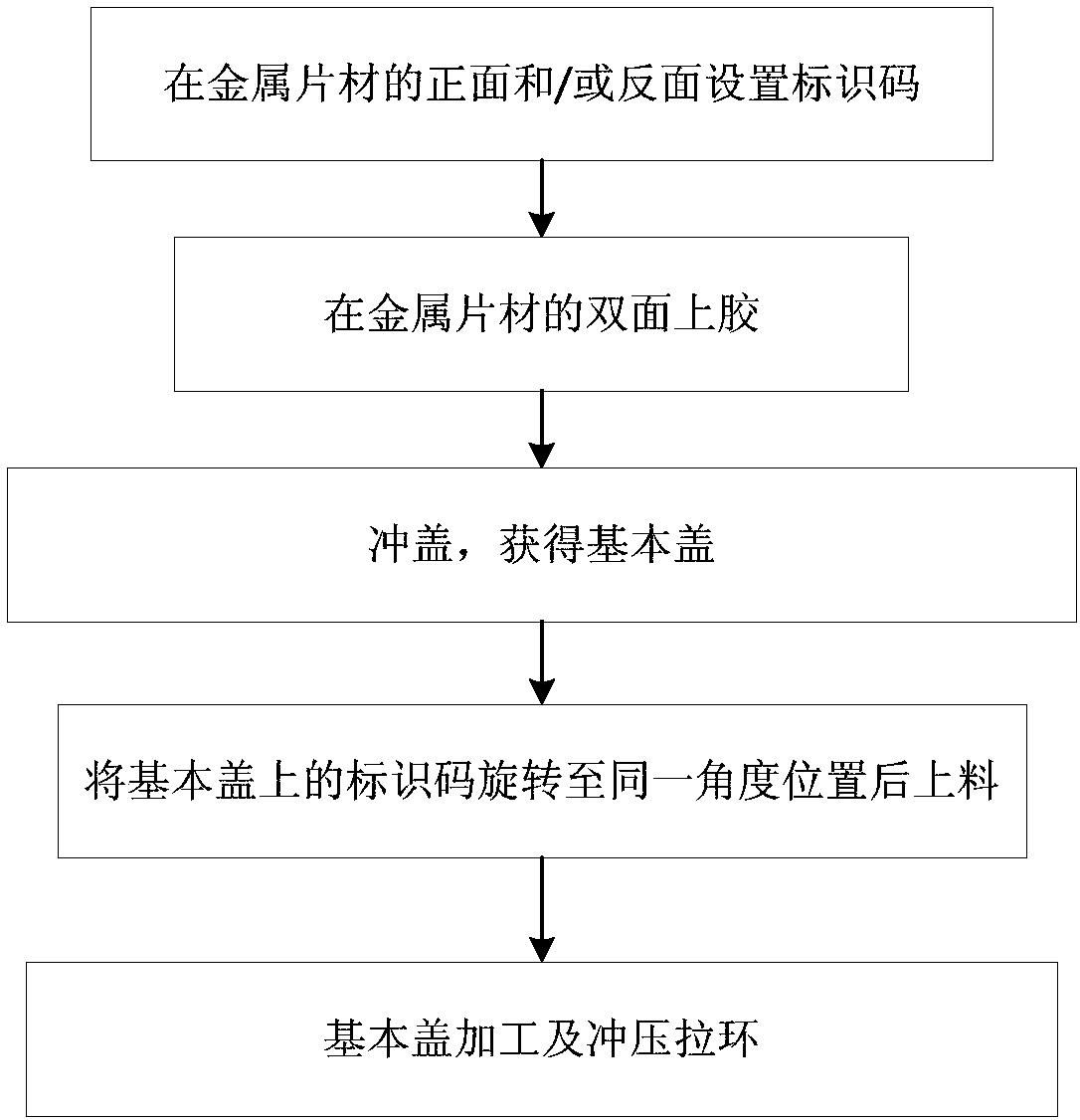

[0044] exist figure 1 , taking the aluminum can top as an example, the existing manufacturing process of the can top is illustrated. The production process of the can top cover includes the following multiple steps: cutting and inner and outer film coating, cover punching, basic cover curling, gluing, blistering, secondary drawing, rivet forming, tangent forming, cover surface reinforcement ring and fingers Formation of holes, formation of tabs, assembly of tabs, formation of embossed characters, formation of reinforcing rings, etc.

[0045]In the prior art, in order to achieve accurate coding at the fixed position of the top cover of the can, the method of coding the finished product of the top cover of the pop can is usually adopted, which will inevitably lead to new problems related to food safety and prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com