Box-packed chemical transmission, separation, coding and sorting system

A sorting system and chemical box technology, used in sorting, packaging, conveyors, etc., can solve problems such as equipment downtime, waste of manpower and material resources, mutual adhesion, etc., to prevent mutual adhesion, shorten service life, and increase wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

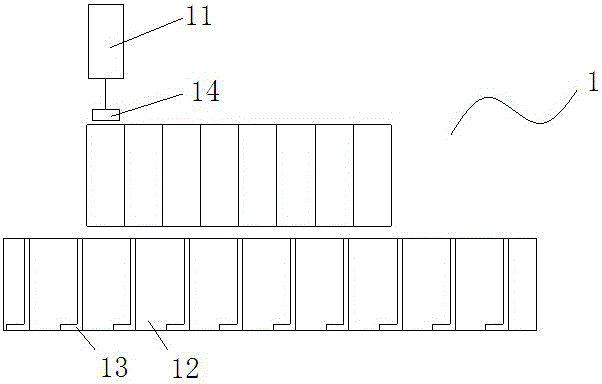

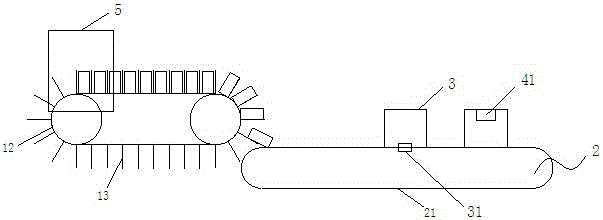

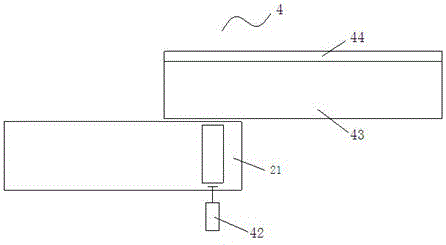

[0023] See Figure 1 to Figure 3 , the present invention has a transmission device 1, a separation device 2, a coding device 3 and a sorting device 4 arranged in sequence;

[0024] The transmission device 1 is arranged on one side of the outlet of the packaging device 5, and the transmission device 1 includes a transmission cylinder 11 and a conveyor belt 12; the transmission cylinder 11 is installed on the other side of the exit of the packaging device 5; the front end of the piston rod of the transmission cylinder 11 is equipped with a photoelectric Switch 14, conveyer belt 12 is installed on the conveying roller, and partition board 13 is installed at equidistant intervals on the conveyer belt 12; Partition board 13 is " L " shape, and the distance between adjacent two partition boards 13 is the independent boxed thing that hangs down. 1.1 to 1.3 times.

[0025] Separation device 2 comprises the separation conveyer belt 21 of submerged installation;

[0026] The coding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com