Dried tofu packaging inkjet printer

A technology of outer packaging and inkjet printers, applied in typewriters, printing devices, printing, etc., can solve problems such as inconsistent positions and directions, easy jamming of iron rods, irregular printing, etc., to achieve clear and accurate inkjet, eliminate The effect of static electricity and inkjet code is accurate and standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

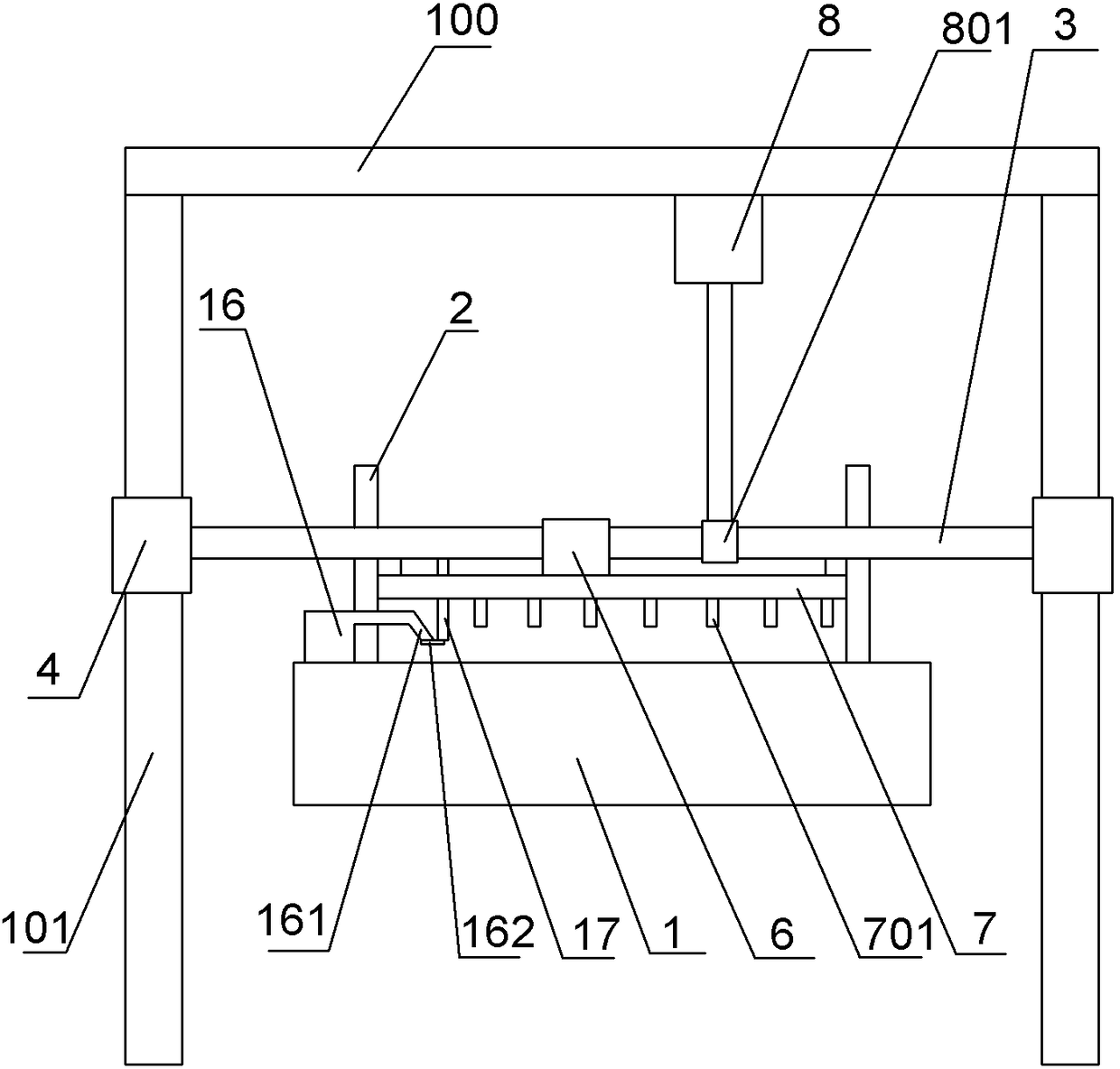

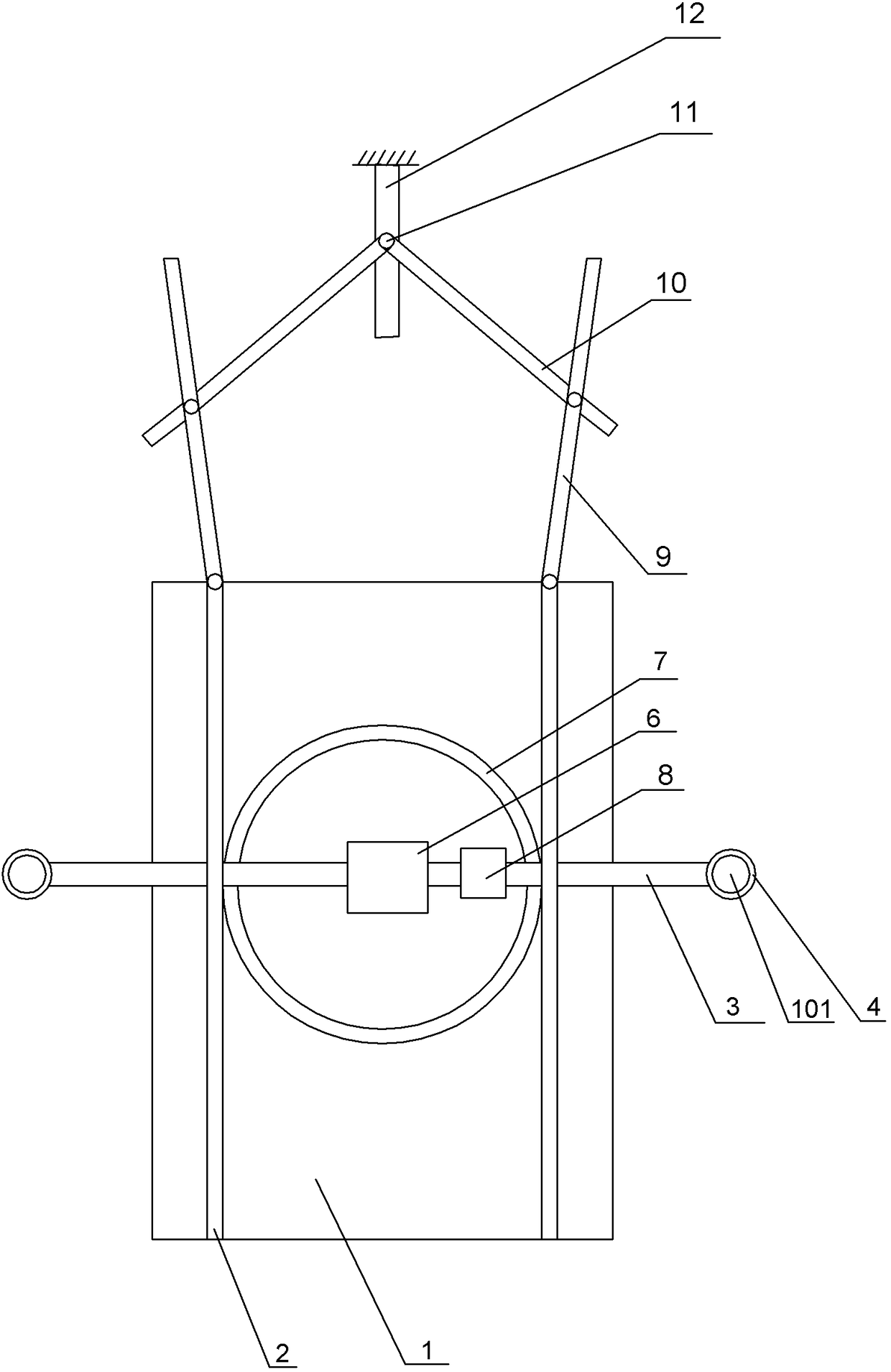

[0025] Such as figure 1 with figure 2 Shown as shown:

[0026] The bean curd outer packaging inkjet printer of the present invention includes a frame 100, a horizontal rod 3, a conveyor belt 1, and a coding device. The horizontal rod 3 is located above the conveyor belt 1, and both ends of the horizontal rod 3 are welded with sliding sleeves 4, and the sliding sleeve 4 is covered with On the support rod 101 on the frame 100 and can slide freely on the support rod 101, the horizontal ring 7 is horizontally welded to the bottom end of the horizontal rod 3, and the coding device 6 is welded to the horizontal rod 3, and the coding device 6 is provided with Infrared sensor, laser nozzle and controller (not shown in the figure), the coding device 6 is located in the middle of the horizontal circle 7, and the horizontal circle 7 is provided with a metal unit. The metal unit can be metal rods evenly arranged on the horizontal circle 7 701 or a metal universal wheel, or a metal surface l...

Embodiment 2

[0030] This embodiment is modified on the basis of the first embodiment. The difference from the embodiment is that the side plate 9 is not opened and closed by manual pushing, but is opened and closed by the drive of the side plate driving device. The specific structure of the drive device is as follows:

[0031] Such as Figure 4 As shown, the side plate driving device includes a cam 19, a turbine 20 and an additional pipe 18. The additional pipe 18 communicates with the blowing device 16, the turbine 20 is rotatably connected in the additional pipe 18, the turbine 20 and the cam 19 are coaxially welded, and the cam 19 is connected to the The side plate 9 abuts, and a torsion spring is provided at the hinge joint of the side plate 9 and the frame 100. The gas in the blowing device 16 enters the additional pipe 18, which drives the rotation of the turbine 20, the rotation of the turbine 20 drives the rotation of the cam 19, and the rotation of the cam 19 drives the side plate 9...

Embodiment 3

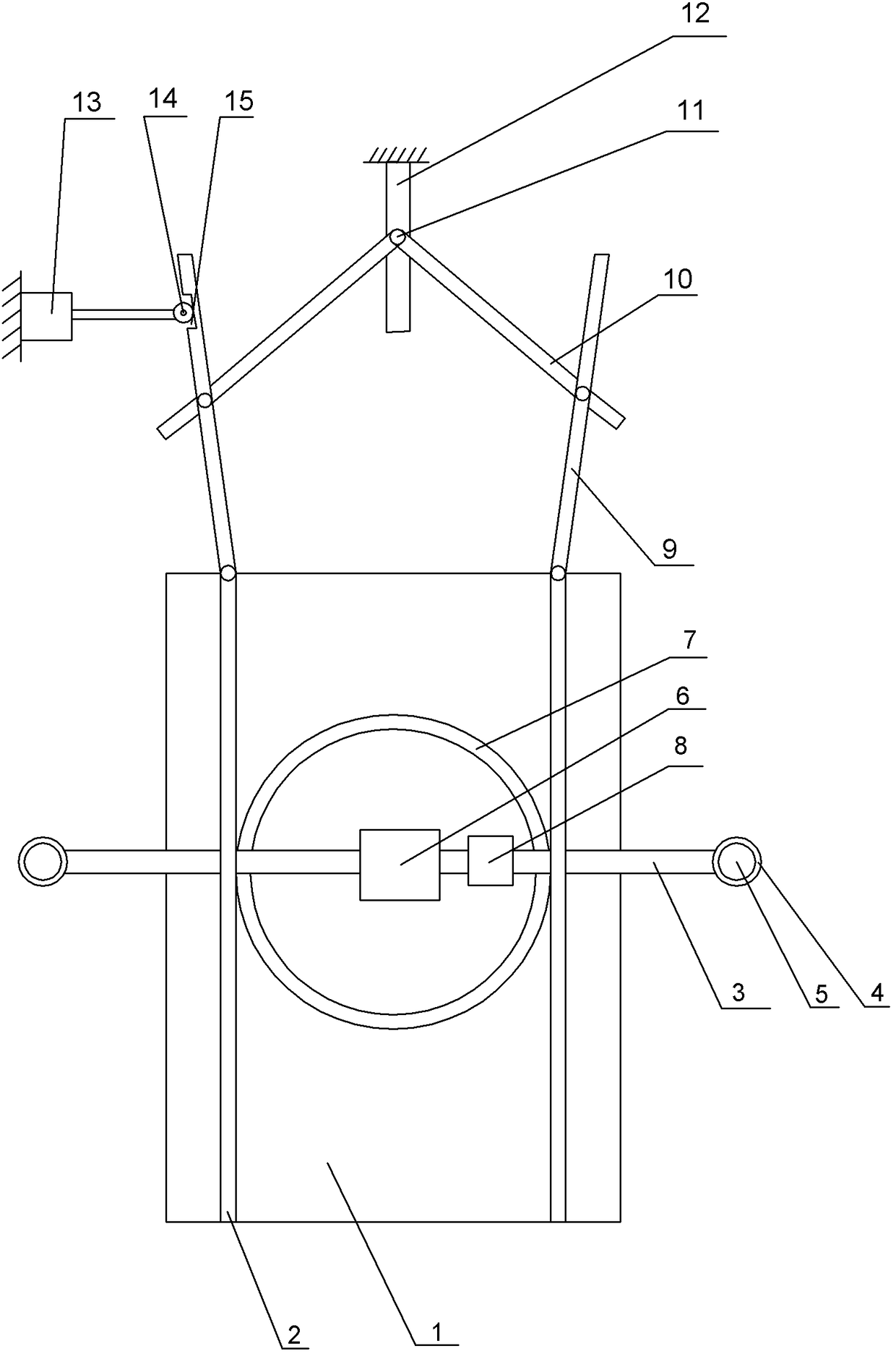

[0033] The difference between this embodiment and the second embodiment is: the structure of the side plate 9 driving device is different, and the specific structure of the side plate driving device is as follows:

[0034] Such as image 3 As shown, the side plate driving device includes a hydraulic cylinder 13, a roller 14 and a rolling groove 15. The hydraulic cylinder 13 is fixedly installed on the frame 100 by bolts. The roller 14 is rotatably connected to one end of the output rod of the hydraulic cylinder 13, and the rolling groove 15 It is opened on the side plate 9, the roller 14 is slidably installed in the rolling groove 15, and a torsion spring is installed at the hinge joint between the side plate 9 and the baffle 2. The output rod of the hydraulic cylinder 13 extends, the roller 14 rolls in the rolling groove 15, the side plate 9 rotates clockwise around the hinged joint of the side plate 9 and the baffle 2, the other side plate 9 rotates counterclockwise, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com