Ink-jet printer for lithium battery processing and method thereof

A lithium battery, inkjet printer technology, applied in chemical instruments and methods, mixers, typewriters, etc., can solve problems such as large use limitations and unadjustable structure, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

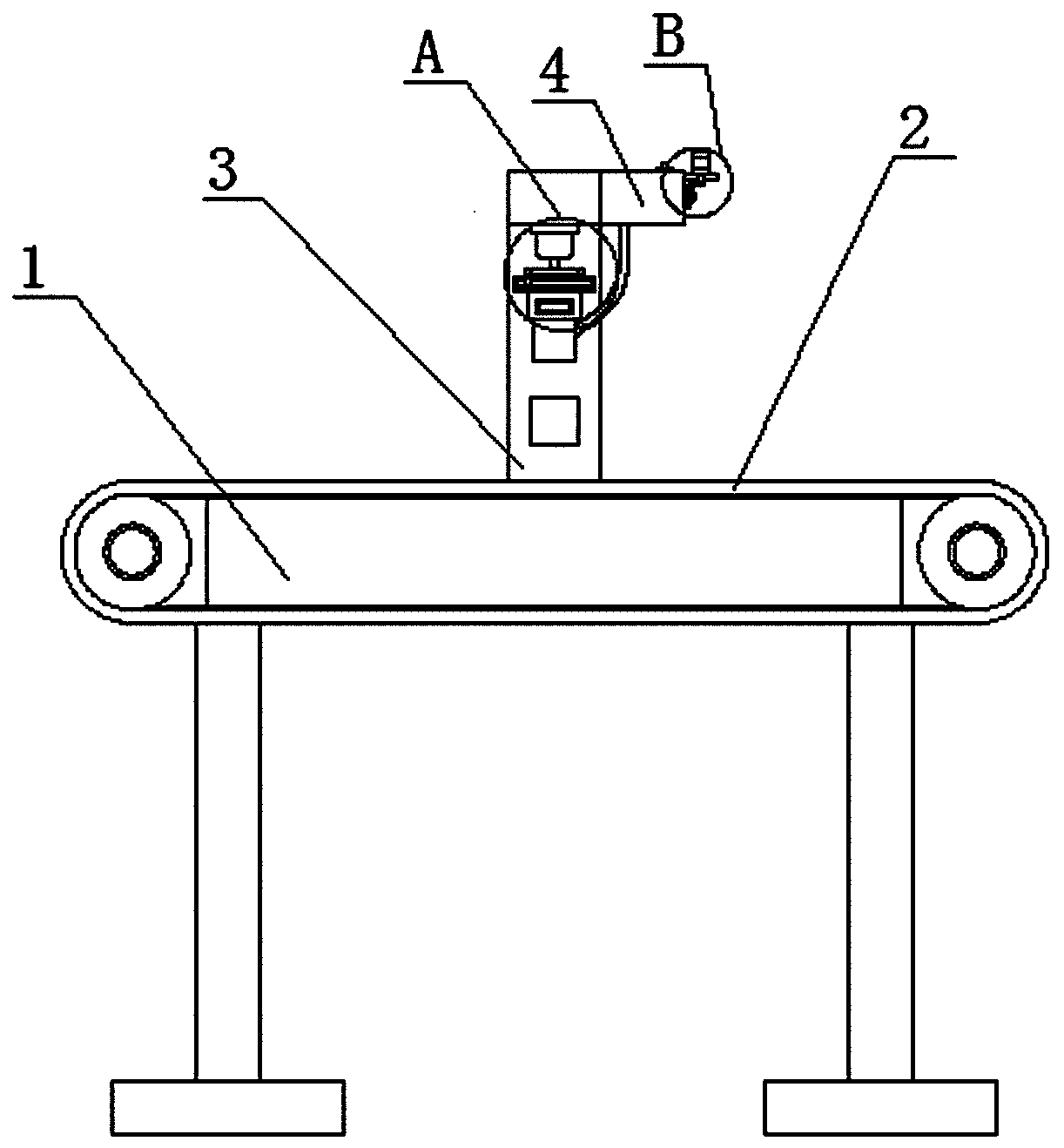

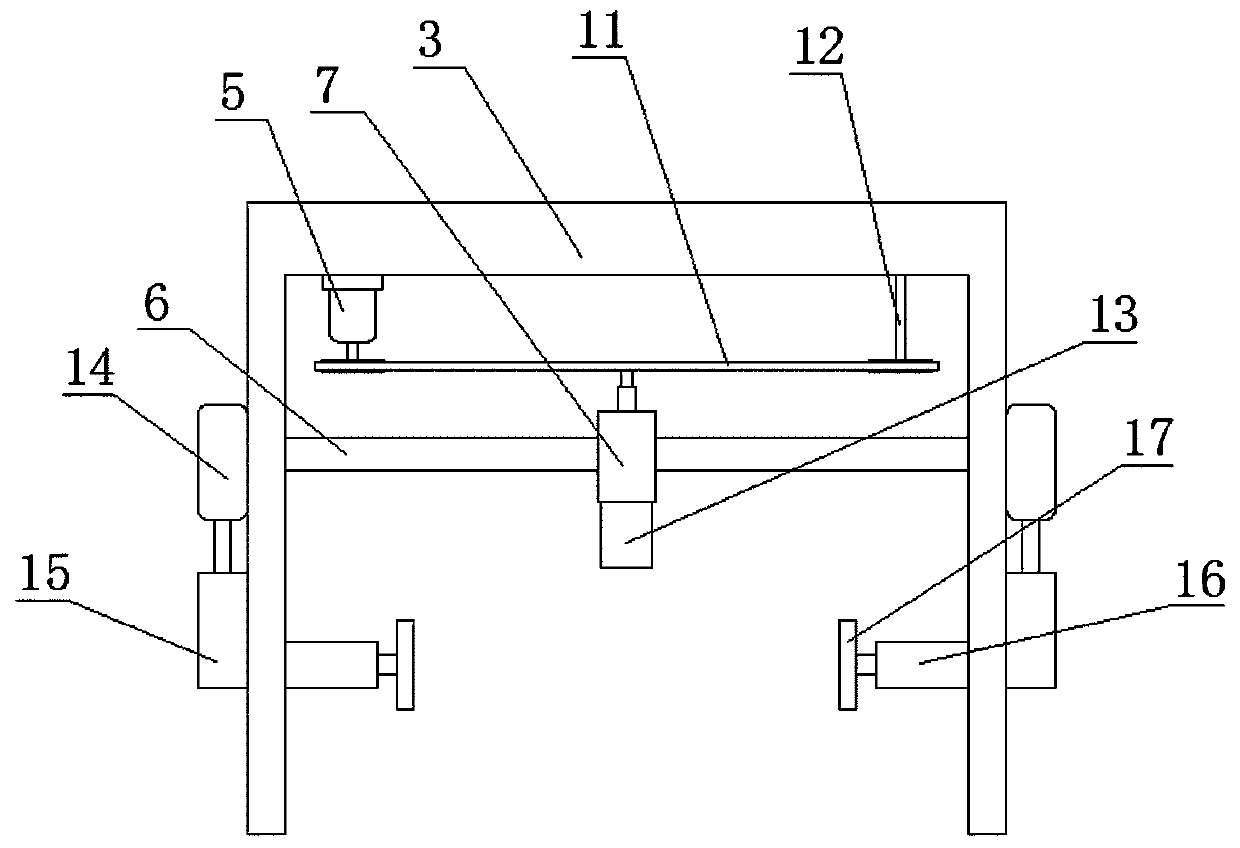

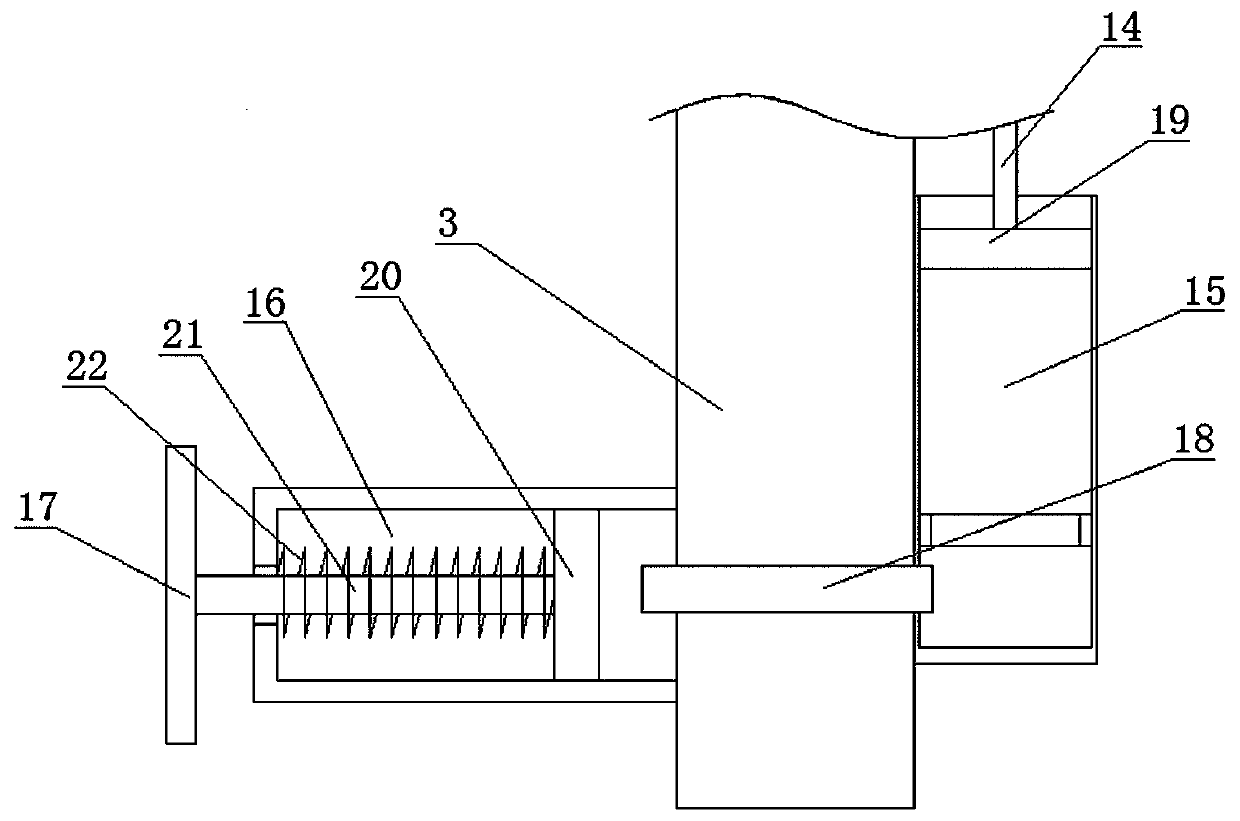

[0032] refer to Figure 1-7 In this embodiment, a kind of inkjet printer for lithium battery processing is proposed, including a workbench 1 and a conveying motor 32, a conveyor belt 2 is connected to the workbench 1, and the conveying motor 32 is connected to the conveyer belt 2, and the workbench 1 is fixedly installed with a U-shaped frame 3, the U-shaped frame 3 is slidably connected with an inkjet printer head 13, and the top of one side of the U-shaped frame 3 is fixedly installed with an ink tank 4, and the inner wall of the bottom side of the ink tank 4 is sealed A hose 31 is fixedly installed, and one end of the hose 31 is connected to the inkjet printer head 13. First, start the two cylinders 14 to drive the sealing plate 19 to move downward. At this time, the gas in the connection box 15 can be passed through When the connecting pipe 18 is transported into the limit cover 16, the slide plate 20 will be pushed to move, so that the two splints 17 can approach each oth...

Embodiment 2

[0034]In this embodiment, a connecting cover 8 is fixedly installed on the top of the inkjet printer head 13, and a drive motor 5 is fixedly installed on the inner wall of one side of the top of the U-shaped frame 3, and a drive motor 5 is fixedly installed on the inner wall of the other side of the top of the U-shaped frame 3. There is a rotating shaft 12, and the rotating shaft 12 and the output shaft of the drive motor 5 are fixedly equipped with a turntable 10, and the two turntables 10 are connected with the same transmission belt 11, and the bottom side of the transmission belt 11 is fixedly installed. 8 is slidably connected with connecting plate 9, and the bottom end of the installation shaft extends into the connecting cover 8 and is connected with the top of connecting plate 9 in rotation. The sliding sleeve on the bar 6 is provided with a slip ring 7, and the inkjet head 13 and the connecting cover 8 are fixedly installed on the bottom and the top of the slip ring 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com