A biopharmaceutical filling system

A biomedicine and filling system technology, applied in the field of biomedicine filling system, can solve the problems of poor sealing and inconvenient filling of biomedicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

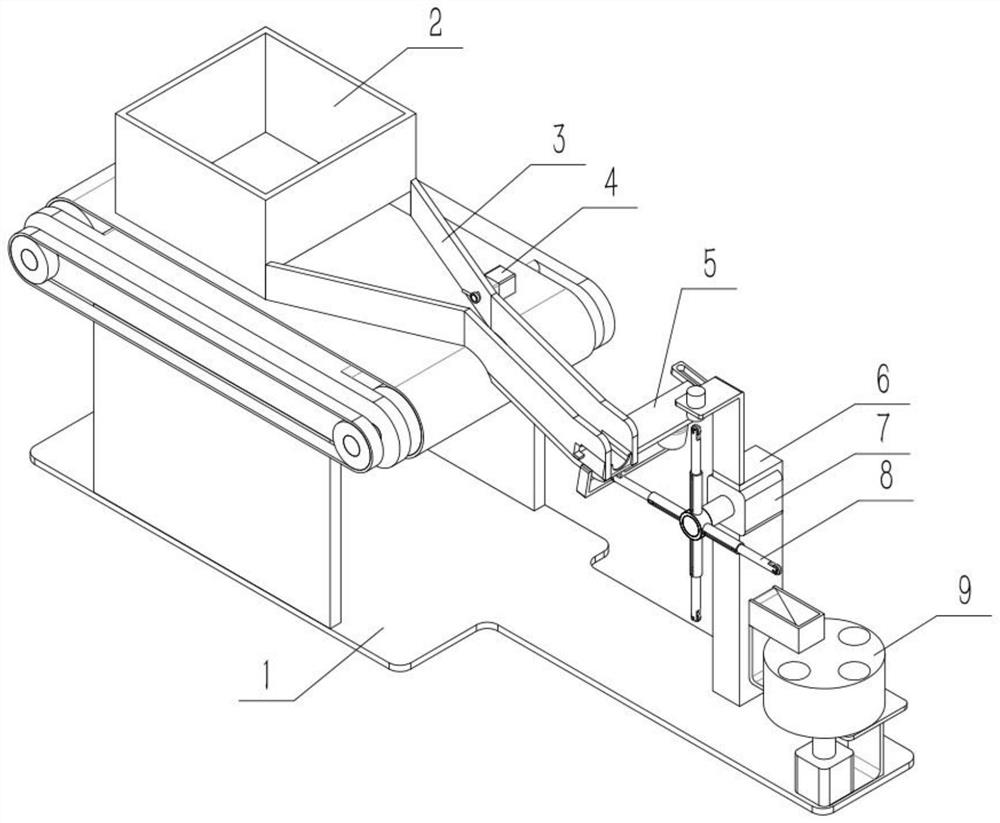

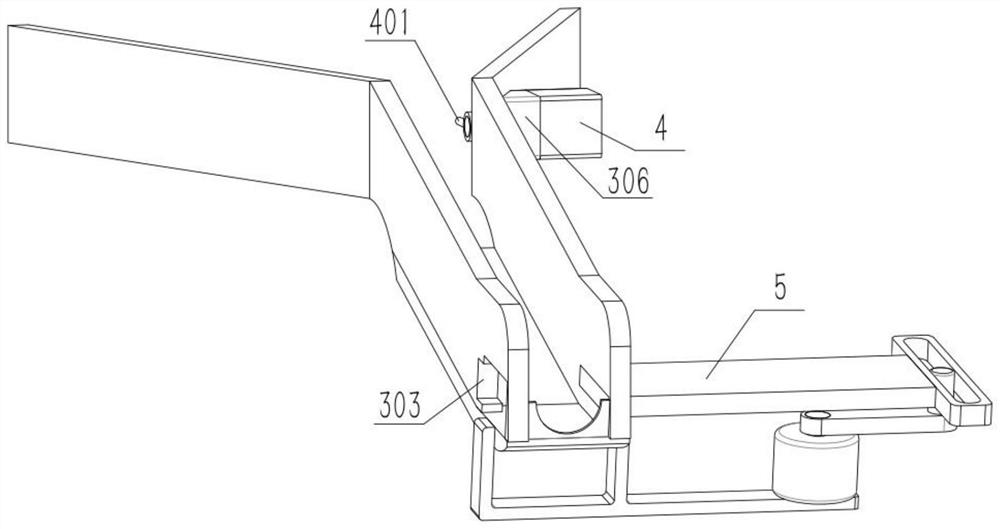

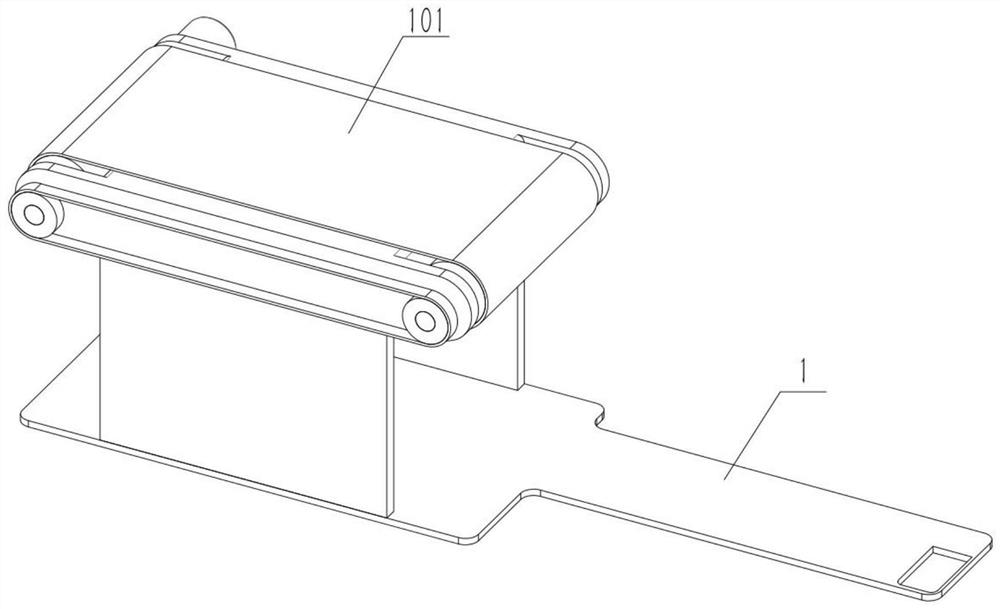

[0033] Such as Figure 1-12 As shown, a biomedical filling system includes a belt conveyor 101, a guide plate 3, a guide plate 301, a slide plate 302, a directional bottle outlet 303 and a baffle 305. The guide plate 3 is mirror-symmetrically arranged with two One, the right ends of the two guide plates 3 are fixedly connected with a guide plate 301 respectively, and the slide plate 302 is fixedly connected with the lower ends of the two guide plates 301, and the slide plate 302 is connected with the right end of the belt conveyor 101, and the orientation outlet 303 is set. On the guide plate 301 at the rear end, the position where the bottle mouth 303 is directed out is connected with the baffle plate 305 , and the baffle plate 305 is affixed to the right end of the downhill plate 302 . The belt conveyer 101 can adopt the existing traditional belt conveyer on the market, and the model can be purchased according to actual needs, and the vial used for filling will be used. The ...

specific Embodiment approach 2

[0035] Such as Figure 1-12 As shown, the biopharmaceutical filling system also includes a storage box 2, a bottle outlet 201 and a frame I202. The frame I 202 is installed on the belt conveyor 101, and the two ends of the bottle outlet 201 are connected with the left ends of the two guide plates 3. Place all the vials that need to be filled in the storage box 2. Only the upside-down vials can be sent out by setting the height of the bottle outlet 201. Combined with starting the belt conveyor 101, the accumulated vials are gradually exported out of the storage box in a single row. 2.

specific Embodiment approach 3

[0037] Such as Figure 1-12 As shown, the biopharmaceutical filling system further includes a sliding interface 304, the position of the sliding interface 304 is set correspondingly to the position of the oriented bottle outlet 303, and the sliding interface 304 is arranged on the guide plate 301 at the front end. Since a small bottle can pass between the two guide plates 301, it is more convenient to directly push out the small bottle from front to back through the sliding interface 304 than to move the small bottle above. Figure 5 Shown should only allow the vial with the bottle mouth to move out toward the left, and the bottom of the bottle with the bottle mouth toward the right will be against the directional bottle outlet 303 and cannot move.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com