Non-ceryl pattern material and manufacturing technology used for investment casting thereof

A production process, wax-based technology, applied in the direction of casting molding equipment, etc., can solve the problems of lowering the melting point and strength of investment molds, affecting the quality of precision casting products, and easy softening and deformation, so as to achieve small deformation, less investment, and not easy to soften Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

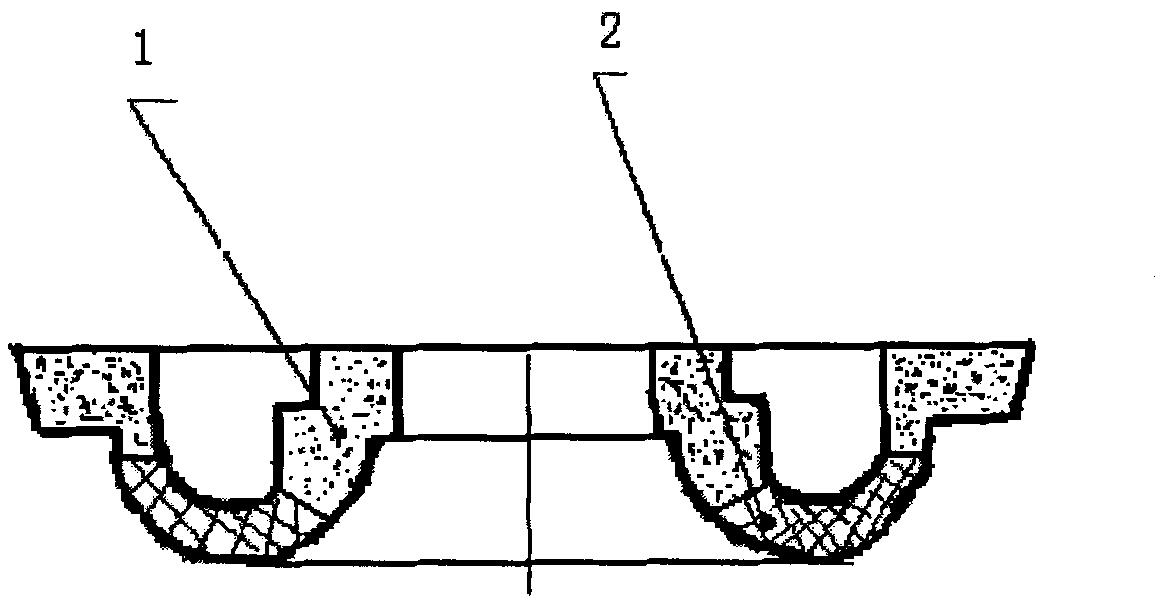

[0014] Embodiment 1: as figure 1 As shown, the turbine casting is made of ZL104 aluminum alloy. The casting has 25 blades evenly distributed, and the upper and lower parts of the casting are connected by 25 blades. The blades need to be represented by coordinates in x, y, and z directions , because the blade is bent, it cannot be pulled out directly in the sand core, and it needs to be made by investment casting.

[0015] The non-wax-based molding material used in the investment casting is composed of the following components in mass percentage: 48.2% of potash, 32.2% of magnesium sulfate, 19.3% of aluminum sulfate, and 0.3% of ferric oxide.

[0016] The manufacturing process of non-wax-based molding materials for investment casting includes the manufacturing process of non-wax-based investment patterns and the manufacturing process of sand cores; wherein, the manufacturing process of non-wax-based investment patterns is: according to the aforementioned mass fraction ratio, ta...

Embodiment 2

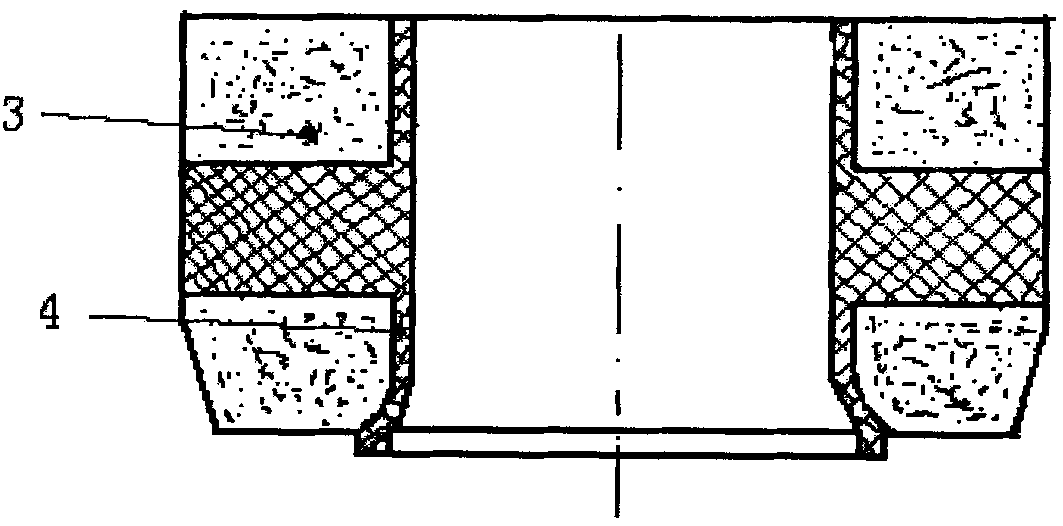

[0017] Embodiment 2: as figure 2 As shown, the guide wheel casting is made of ZL104 aluminum alloy, and the inner and outer circles of the casting are connected by 20 blades, all of which are non-machined surfaces, and the roughness requirement reaches R a 6.3μm, requiring 20 blades to be evenly distributed; due to the high roughness requirements of the inner cavity and blades, it needs to be manufactured by investment casting.

[0018] The non-wax-based molding material used in the investment casting is composed of the following components in mass percentage: 48.2% of potash, 32.2% of magnesium sulfate, 19.3% of aluminum sulfate, and 0.3% of ferric oxide.

[0019] The manufacturing process of non-wax-based molding materials for investment casting includes the manufacturing process of non-wax-based investment patterns and the manufacturing process of sand cores; wherein, the manufacturing process of non-wax-based investment patterns is: according to the aforementioned mass f...

Embodiment 3

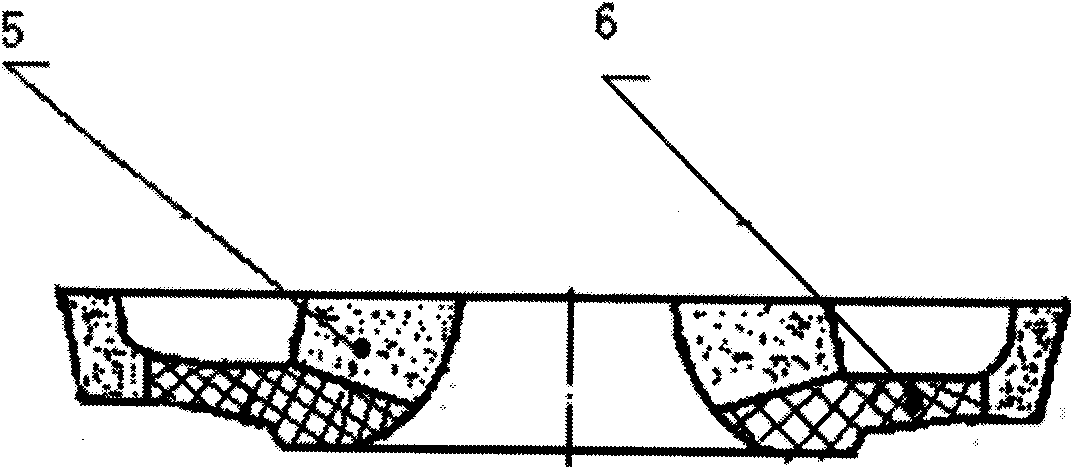

[0020] Embodiment 3: as image 3 As shown, the impeller casting is made of ZL104 aluminum alloy, and the casting has 24 blades evenly distributed, with a tolerance of ±10' for uneven division, and the upper and lower parts of the casting are connected by 24 blades; because the shape of the blade is In the three-dimensional bending state, it cannot be pulled out directly in the sand core, and it needs to be made by investment casting.

[0021] The non-wax-based molding material used in the investment casting is composed of the following components in mass percentage: 48.2% of potash, 32.2% of magnesium sulfate, 19.3% of aluminum sulfate, and 0.3% of ferric oxide.

[0022] The manufacturing process of non-wax-based molding materials for investment casting includes the manufacturing process of non-wax-based investment patterns and the manufacturing process of sand cores; wherein, the manufacturing process of non-wax-based investment patterns is: according to the aforementioned mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com