Mandril for copper alloy pipe planetary rolling mill and manufacturing method thereof

A planetary rolling mill, copper alloy technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of low yield, short service life, difficult mandrel, etc., and achieve simple preparation process and time-saving processing Cost saving and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

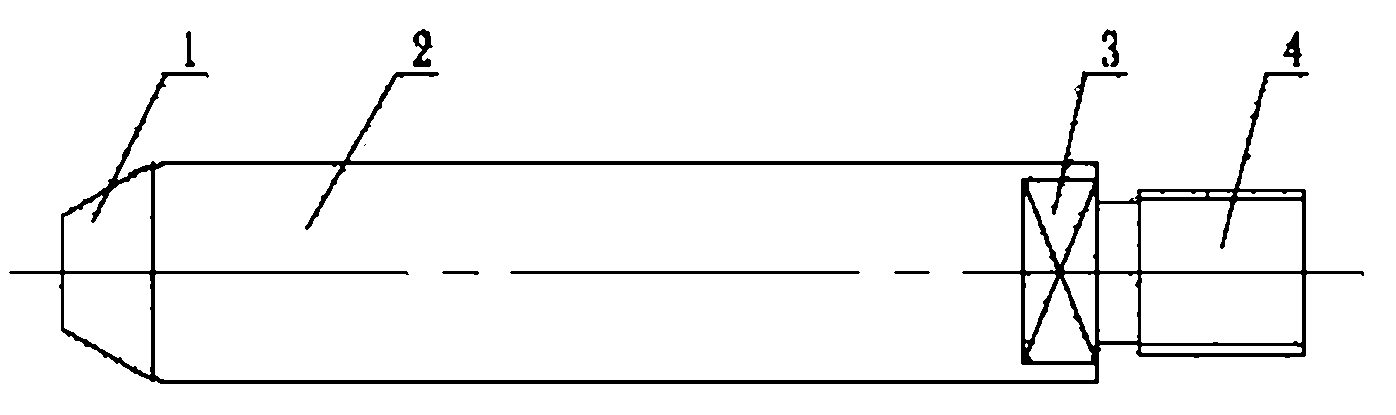

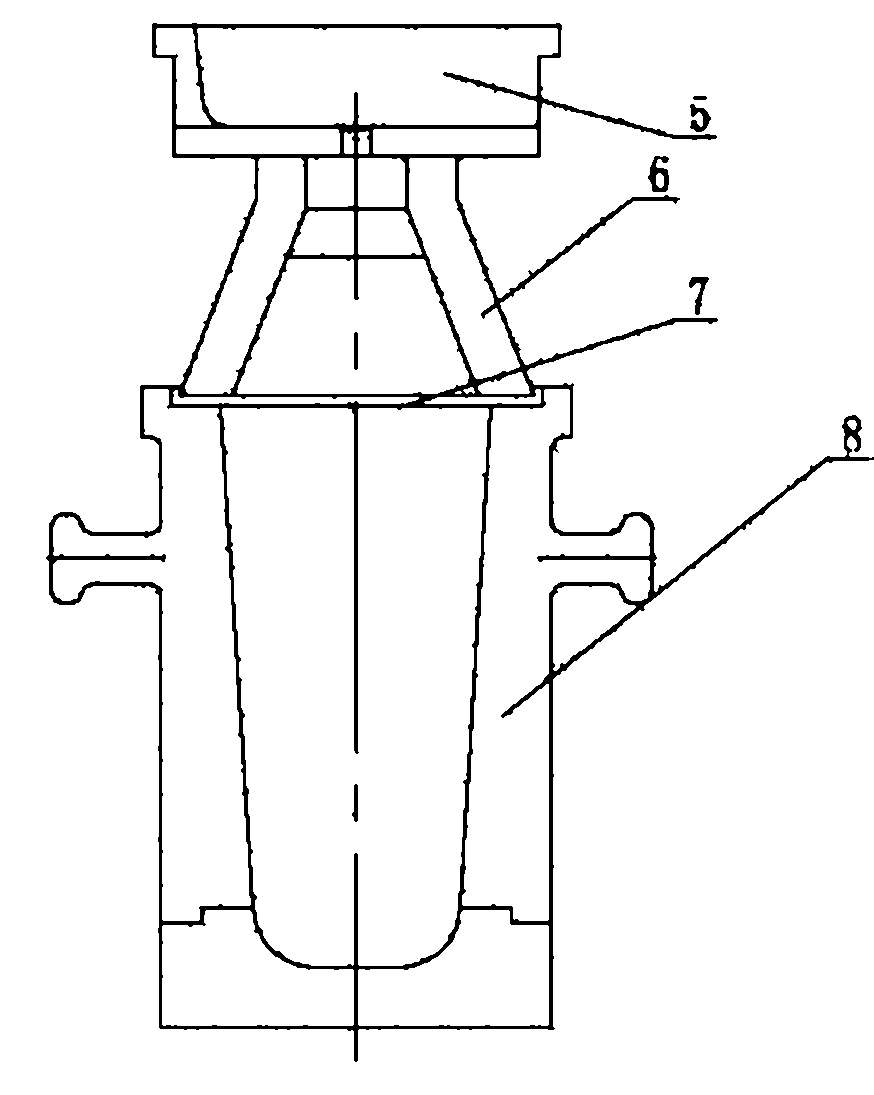

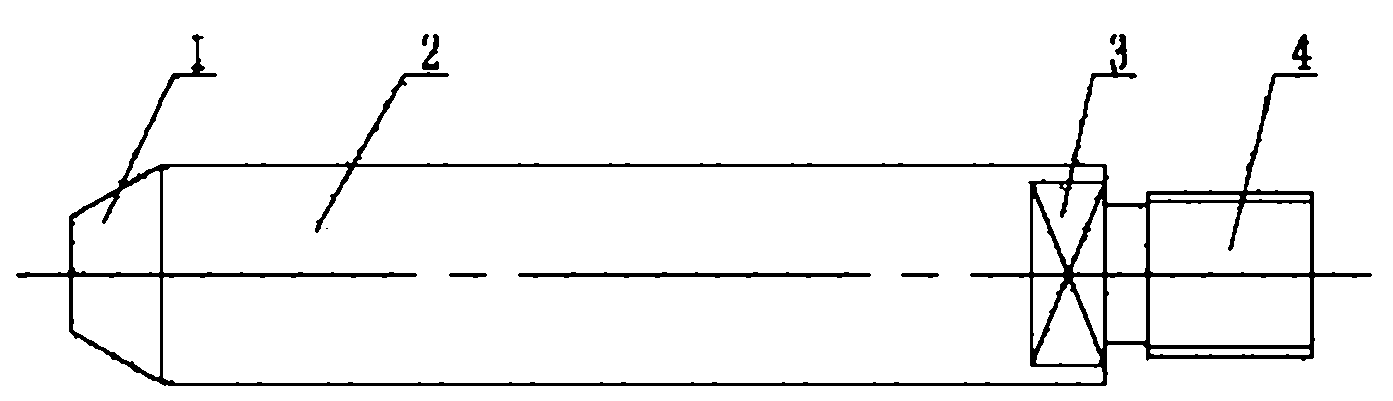

Image

Examples

Embodiment 1

[0018] Chemical composition (weight percent, balance is iron)

[0019] nickel

chromium

molybdenum

manganese

titanium

vanadium

aluminum

35

19

9

0.8

1.2

0.1

0.05

[0020] A method for making a mandrel for a copper alloy tube planetary rolling mill, comprising the following process steps:

[0021] (1) Batching: batching is carried out according to the composition of the mandrel;

[0022] (2) Vacuum induction furnace smelting: add: 1# electrolytic nickel, metal chromium, 1# metal manganese, molybdenum rod and 20# carbon steel in the crucible of the vacuum furnace in sequence, after heating up and melting, add: sponge titanium , A00 aluminum ingot and V-2 metal vanadium; the vacuum degree of the vacuum induction furnace is: 1MPa; the melting temperature is: 1630°C, and the melting time is 15 minutes to form a molten metal;

[0023] (3) Casting ingot mould: the above-mentioned molten metal is passed thro...

Embodiment 2

[0027] Chemical composition (weight percent, balance is iron)

[0028] nickel

chromium

molybdenum

manganese

titanium

vanadium

aluminum

40

21

12

1.8

1.5

0.5

0.2

[0029] A method for making a mandrel for a copper alloy tube planetary rolling mill, comprising the following process steps:

[0030] (1) Batching: batching is carried out according to the composition of the mandrel;

[0031] (2) Vacuum induction furnace smelting: add: 1# electrolytic nickel, metal chromium, 1# metal manganese, molybdenum rod and 20# carbon steel in the crucible of the vacuum furnace in sequence, after heating up and melting, add: sponge titanium , A00 aluminum ingot and V-2 metal vanadium; the vacuum degree of the vacuum induction furnace is: 6.7×10 -1 MPa; the melting temperature is: 1680°C, the melting time is 6 minutes, and the molten metal is formed;

[0032] (3) Casting ingot mould: the above-mentioned molten metal ...

Embodiment 3

[0036] Chemical composition (weight percent, balance is iron)

[0037] nickel

chromium

molybdenum

manganese

titanium

vanadium

aluminum

38

20

10

1.5

1.3

0.3

0.1

[0038] A method for making a mandrel for a copper alloy tube planetary rolling mill, comprising the following process steps:

[0039] (1) Batching: batching is carried out according to the composition of the mandrel;

[0040] (2) Vacuum induction furnace smelting: add: 1# electrolytic nickel, metal chromium, 1# metal manganese, molybdenum rod and 20# carbon steel in the crucible of the vacuum furnace in sequence, after heating up and melting, add: sponge titanium , A00 aluminum ingot and V-2 metal vanadium; the vacuum degree of the vacuum induction furnace is: 8×10 -1 MPa; the melting temperature is: 1650°C, the melting time is 10 minutes, and the molten metal is formed;

[0041] (3) Casting ingot mold: Casting ingot mold: the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com