Printed circuit board and fabrication method thereof

A technology for printed circuit boards and manufacturing methods, applied in the directions of printed circuits, printed circuit manufacturing, printed circuit secondary processing, etc. Pad and circuit defects, stable performance, small amount of suspended nickel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are described in detail below:

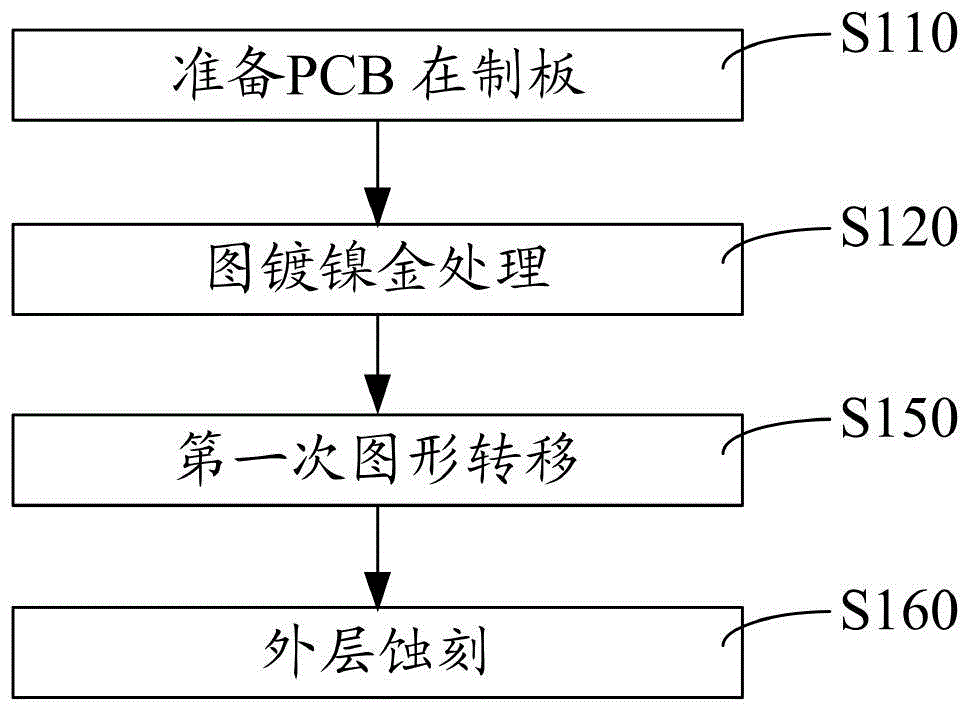

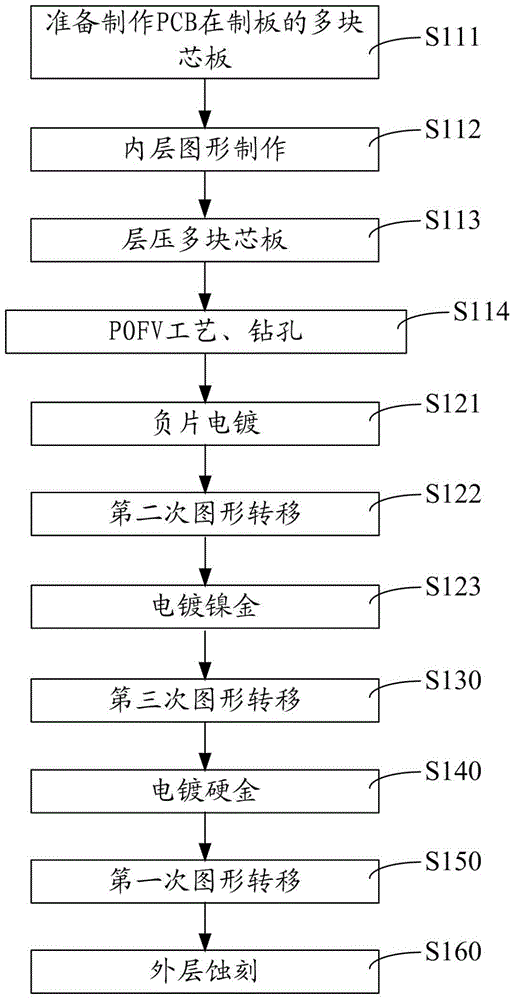

[0034] Such as figure 1 , figure 2 Shown, a kind of manufacturing method of printed wiring board comprises the following steps:

[0035] S110 Prepare PCB in process;

[0036] Specifically, the steps of preparing the PCB-in-process include:

[0037] S111 Prepare to make multiple core boards of the PCB in process;

[0038] S112 Inner layer graphic production: inner layer graphic production through inner layer graphic transfer, inner layer etching and other processes;

[0039] S113 Lamination of multiple core boards: stacking multiple core boards, moving the laminated multiple core boards into a pressing furnace for pressing by hot pressing to form a multi-layer board;

[0040] S114POFV process and drilling: make holes according to the design requirements;

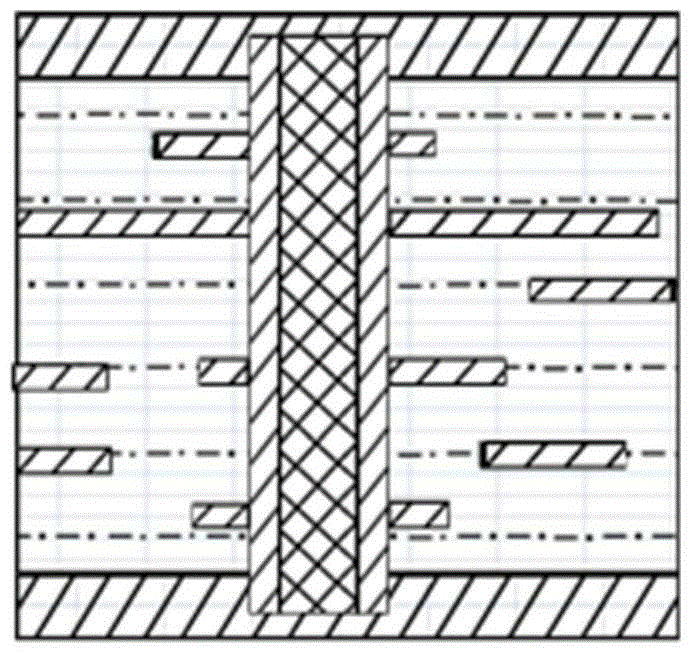

[0041] Adopt the above-mentioned process to prepare the PCB in-process board, and prepare the cross-sectional schematic diagram of the circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com