Chemical nickel solution applied to wafer-level packaging chemical nickel-gold process

A technology of wafer-level packaging and chemical nickel gold, which is applied in the direction of metal material coating process, liquid chemical plating, coating, etc., can solve the problems of increased load, low activity, and high nickel tank parameters, etc., to prevent Missed plating conditions, reduced deposition potential, and good stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A nickel plating solution:

[0061] Nickel salt: nickel sulfate heptahydrate 30g / L;

[0062] Complexing agent: malic acid 15g / L, succinic acid 15g / L, glycine 10g / L;

[0063] Reducing agent: sodium hypophosphite 25g / L;

[0064] Stabilizer: Thiourea 2mg / L

[0065] Impurity remover: 2-(1-hydroxyethyl)pyridine: 5mg / L

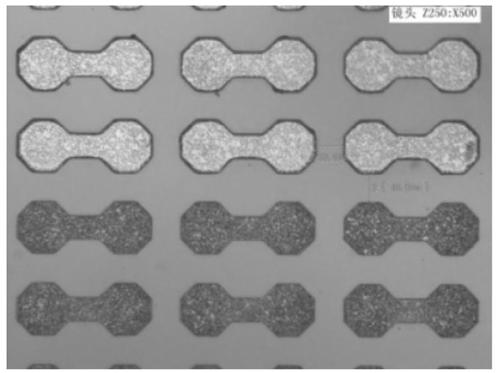

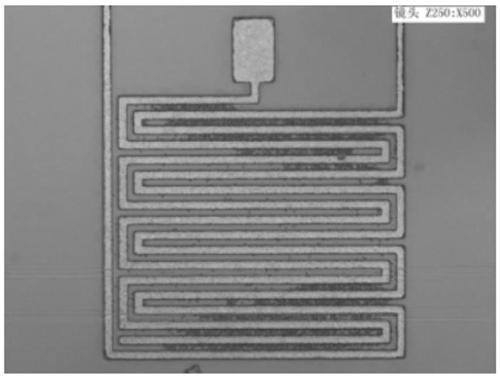

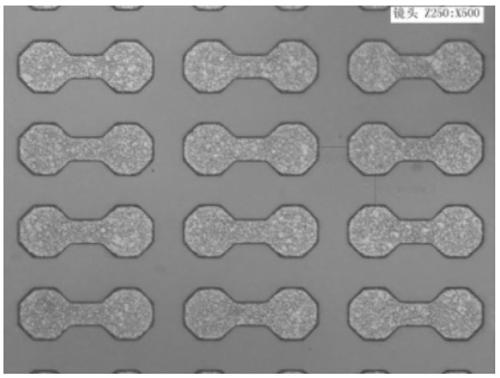

[0066] Adopt the plating solution and parameter of comparative implementation 1, just add 2-(1-hydroxyethyl)pyridine in the nickel plating solution, then utilize the patterned wafer to carry out normal process, normal parameter carries out electroless nickel plating, as Figure three with Figure four . Due to the addition of 2-(1-hydroxyethyl)pyridine, missing plating and penetration plating did not occur.

Embodiment 2

[0068] A traditional nickel plating solution:

[0069] Nickel salt: nickel acetate 25g / L;

[0070] Complexing agent: citric acid 10g / L, malic acid 15g / L, lactic acid 10g / L;

[0071] Reducing agent: sodium hypophosphite 25g / L;

[0072] Stabilizer: phenylthiourea 4mg / L

[0073] Impurity remover: bipyridine 20mg / L

[0074] Use 20% ammonia water or potassium hydroxide solution to adjust the pH value to 4.7, the temperature is 82±2°C, use the patterned wafer to carry out the normal process, and perform electroless nickel plating with normal parameters, without missing plating and penetration plating.

Embodiment 3

[0076] A traditional nickel plating solution:

[0077] Nickel salt: nickel sulfate heptahydrate 28g / L;

[0078] Complexing agent: citric acid 10g / L, malic acid 15g / L, lactic acid 10g / L;

[0079] Reducing agent: sodium hypophosphite 25g / L;

[0080] Stabilizer: sodium thiosulfate 2mg / L;

[0081] Impurity remover: 2-chloro-5-hydroxypyridine 5mg / L, bipyridine 10mg / L;

[0082] Use 20% ammonia water or potassium hydroxide solution to adjust the pH value to 4.7, the temperature is 82±2°C, use the patterned wafer to carry out the normal process, and perform electroless nickel plating with normal parameters, without missing plating and penetration plating.

[0083] By comparing the examples and the specific examples, it is concluded that the above impurity removers can be used alone or any two of them can achieve the effects of no missing plating and seepage plating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com