High-reliability type chemical palladium plating liquor and cyanide-free chemical nickel-palladium-gold processing method

A processing method and reliable technology, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of high cost, lack of gold wire, and difficult control of process conditions, etc., to achieve good economy Benefits and social benefits, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

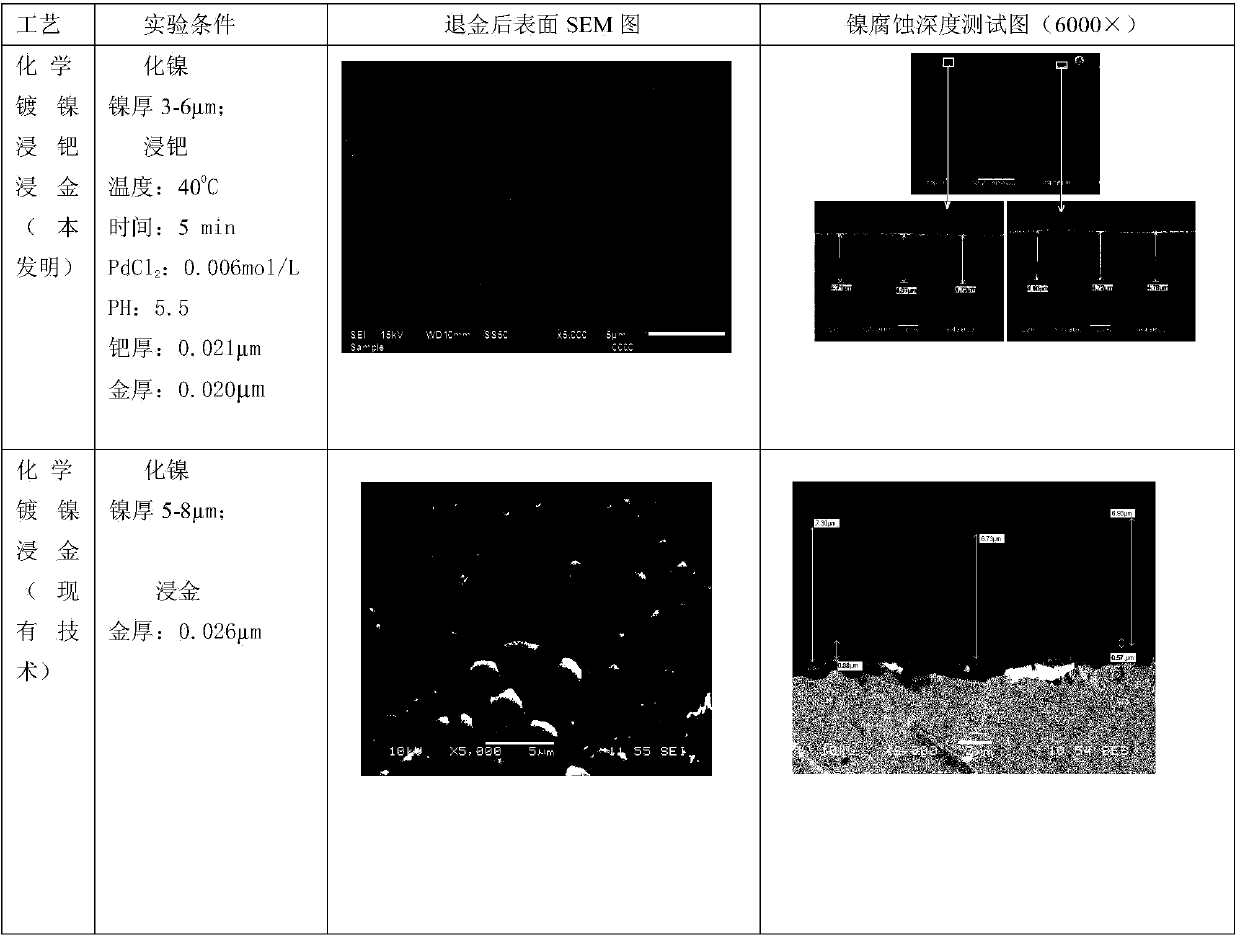

Embodiment 1

[0036] The high-reliability electroless palladium plating solution of the present invention is mainly composed of the components in the following concentration ratios:

[0037] Complexing agent 0.20mol / L;

[0038] Palladium chloride 0.004mol / L;

[0039] Additive 40ppm;

[0040] The rest is water, among which the pH of the plating solution is 7.0, the temperature during palladium immersion is 45°C, and the time is 3 minutes.

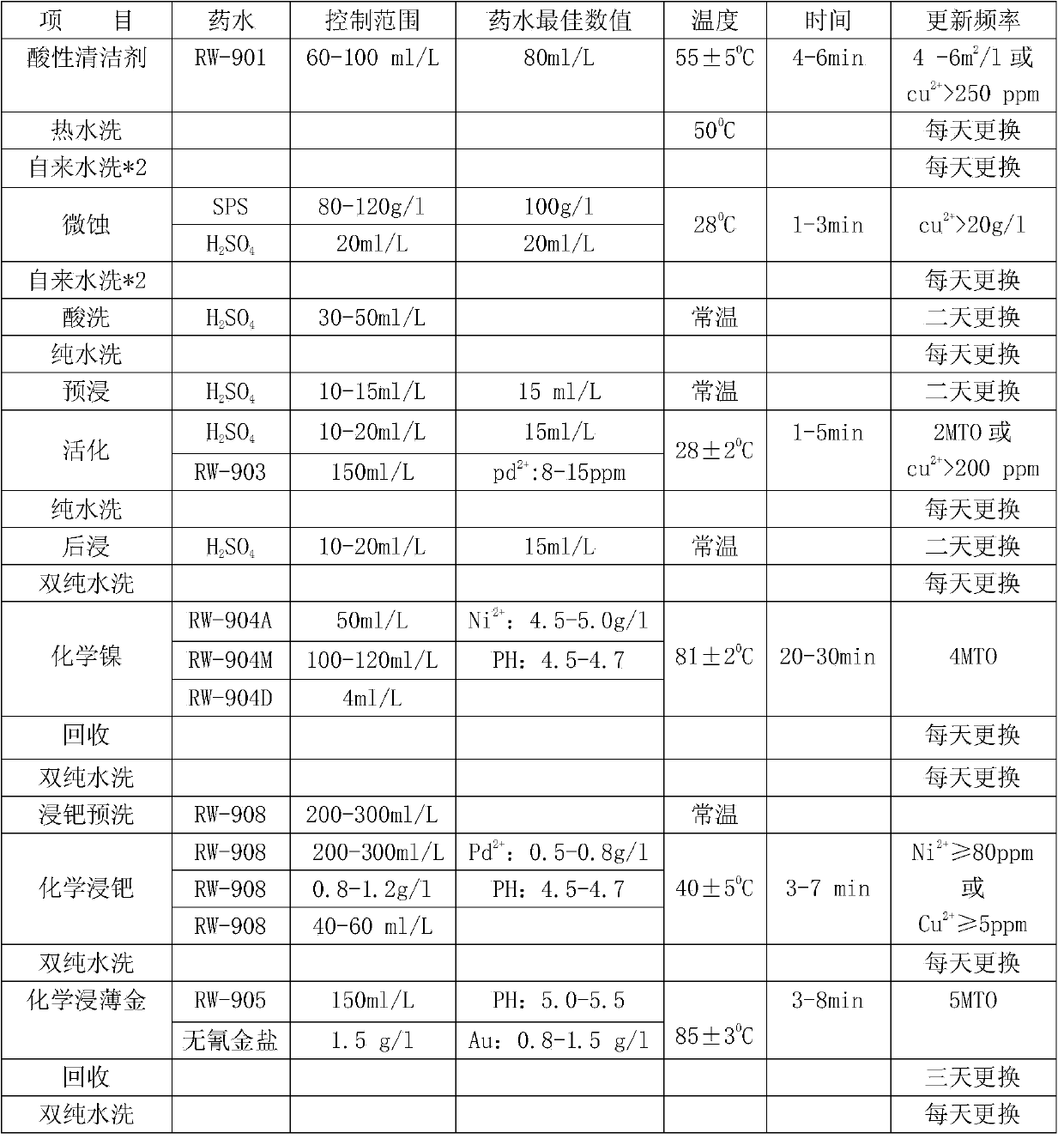

[0041] Electroless nickel plating and palladium immersion gold include the following main processes:

[0042] 1. Acid degreasing (using RW-901 syrup, also known as acid cleaning);

[0043] 2. Micro-etching (using SPS / H 2 SO 4 Potion);

[0044] 3. Activation (using RW-903 / PdSO 4 Potion);

[0045] 4. Chemical nickel plating (using RW-904 series potion);

[0046] 5. Chemical immersion palladium (using PdCl 2 Potion);

[0047] 6. Chemical immersion gold (using RW-905R potion).

[0048] among them,

[0049] For acid cleaning, the acid cleaning agent used is RW-901 syrup with a ...

Embodiment 2

[0060] The high-reliability electroless palladium plating solution of the present invention is mainly composed of the components in the following concentration ratios:

[0061] Complexing agent 0.40mol / L;

[0062] Palladium chloride 0.0010mol / L;

[0063] Additive 20ppm;

[0064] The rest is water, among which the pH of the plating solution is 4.5, the temperature during palladium immersion is 35°C, and the time is 7 minutes.

[0065] Electroless nickel plating and palladium immersion gold include the following main processes:

[0066] 1. Acid degreasing (using RW-901 syrup, also known as acid cleaning);

[0067] 2. Micro-etching (using SPS / H 2 SO 4 Potion);

[0068] 3. Activation (using RW-903 / PdSO 4 Potion);

[0069] 4. Chemical nickel plating (using RW-904 series potion);

[0070] 5. Chemical immersion palladium (using PdCl 2 Potion);

[0071] 6. Chemical immersion gold (using RW-905R potion).

[0072] among them,

[0073] For acid cleaning, the acid cleaning agent used is RW-901 syrup with a...

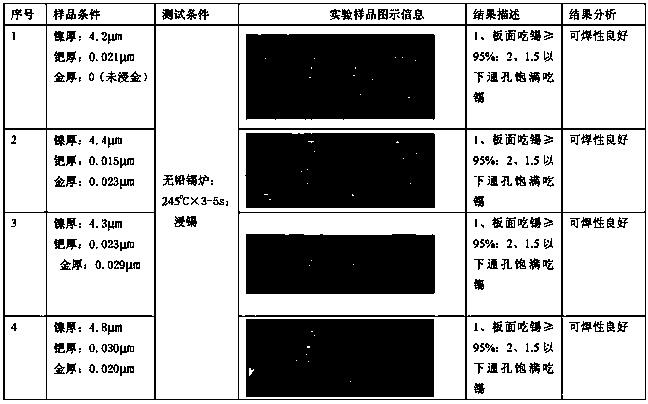

Embodiment 3

[0085] The high-reliability electroless palladium plating solution of the present invention is mainly composed of the components in the following concentration ratios:

[0086] Complexing agent 0.25mol / L;

[0087] Palladium chloride 0.005mol / L;

[0088] Additive 25ppm;

[0089] The rest is water, of which the pH of the plating solution is 5.0, the temperature during palladium immersion is 35°C, and the time is 6 minutes.

[0090] Electroless nickel plating and palladium immersion gold include the following main processes:

[0091] 1. Acid degreasing (using RW-901 syrup, also known as acid cleaning);

[0092] 2. Micro-etching (using SPS / H 2 SO 4 Potion);

[0093] 3. Activation (using RW-903 / PdSO 4 Potion);

[0094] 4. Chemical nickel plating (using RW-904 series potion);

[0095] 5. Chemical immersion palladium (using PdCl 2 Potion);

[0096] 6. Chemical immersion gold (using RW-905R potion).

[0097] among them,

[0098] For acid cleaning, the acid cleaning agent used is RW-901 syrup with a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com