No-board-edge nickel-gold technology of circuit board

A circuit board and process technology, which is applied in the field of circuit board edgeless nickel-gold process, can solve the problems of chemical nickel wire pollution, raw material and labor waste, etc., and achieve the effect of saving consumption and ensuring direction positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

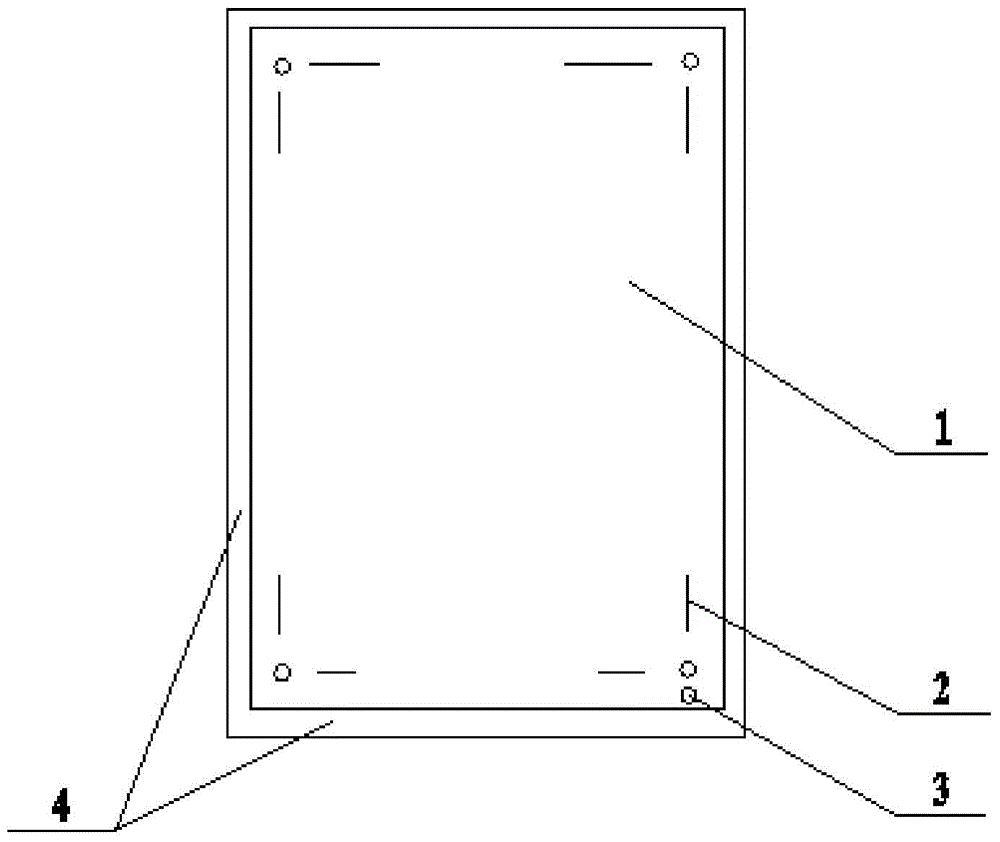

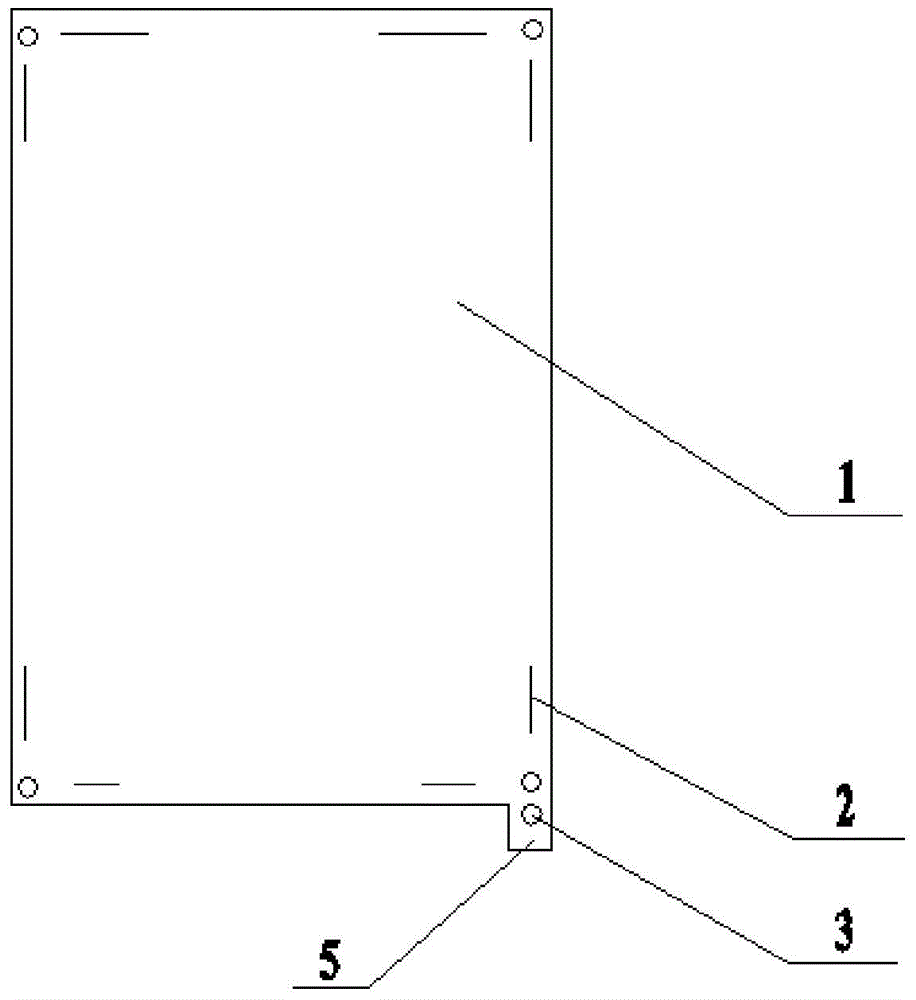

[0018] Describe below in conjunction with accompanying drawing and specific embodiment:

[0019] A circuit board edgeless nickel-gold process, comprising:

[0020] S1. Cutting the circuit board 1 substrate (plate type: FR-4TG140A grade plate, length 622mm, width 435mm, plate thickness 1.5mm, copper thickness 1 / 1OZ, the width of the reserved process side 4 is 10.2mm in the width direction , length direction 13.48mm), drilling (Shenzhen Han’s drilling machine, spindle speed 200,000 rpm, drill tape P02E57032A0.drl, minimum aperture 0.4mm), after electroless copper deposition, use a 50 times microscope to observe the backlight level as Level 9; followed by whole board electroplating, current density 15ASF, electroplating time 30min;

[0021] S2. After the pretreatment of the dry film on the electroplated circuit board, paste the dry film in the clean room (Changxing dry film HT-115T21.00inch, 600ft, film pressure 3.8kg / cm 2 , film temperature 110°C), after film application, let ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com