Preparation method of zinc oxide nanometer wafer array with large area and high orientation

A zinc oxide nanometer and high-orientation technology, which is applied in the field of preparation of nanomaterial alignment, can solve the problem of single product morphology, and achieve the effects of simple process, low reaction temperature and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

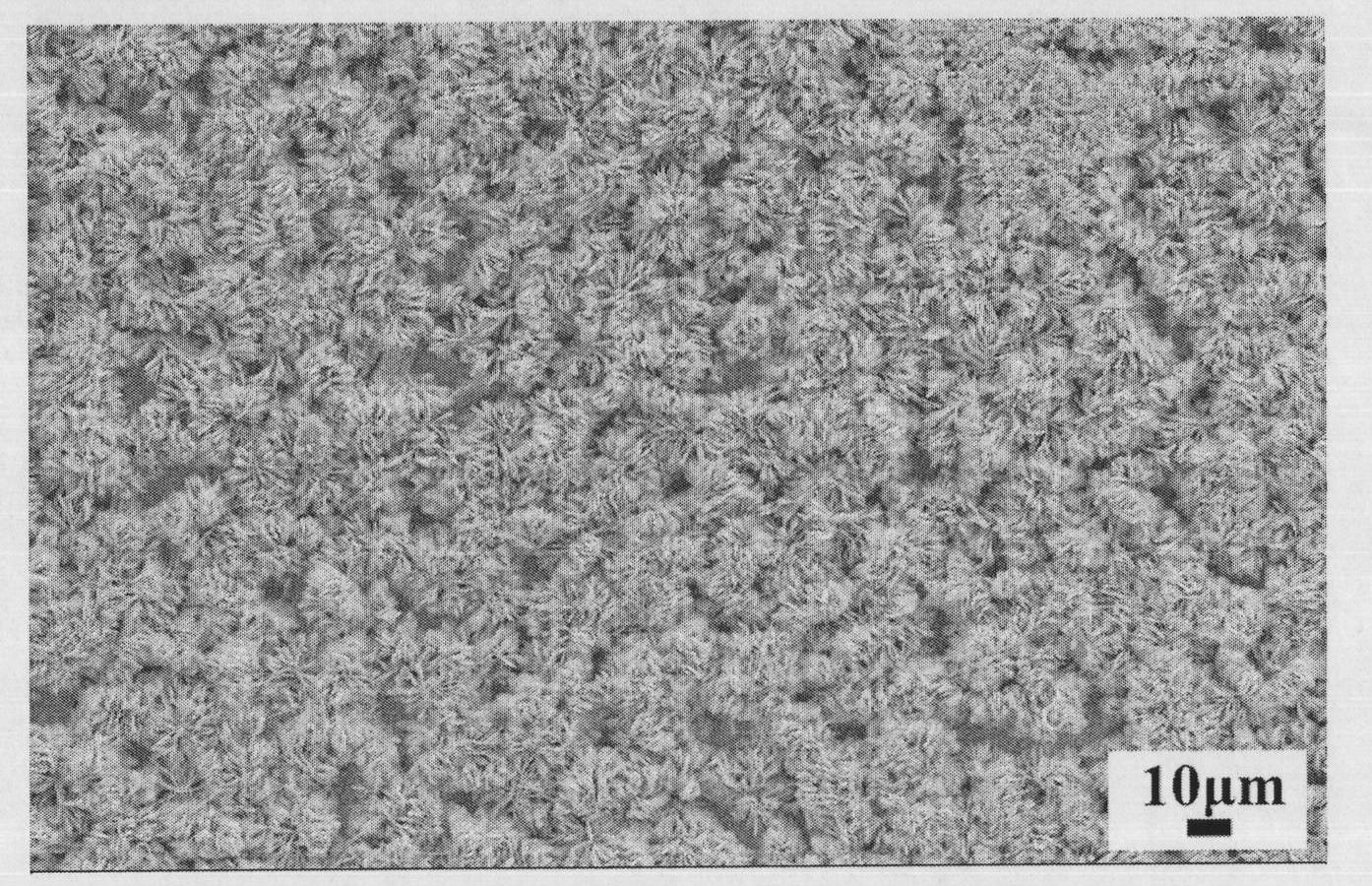

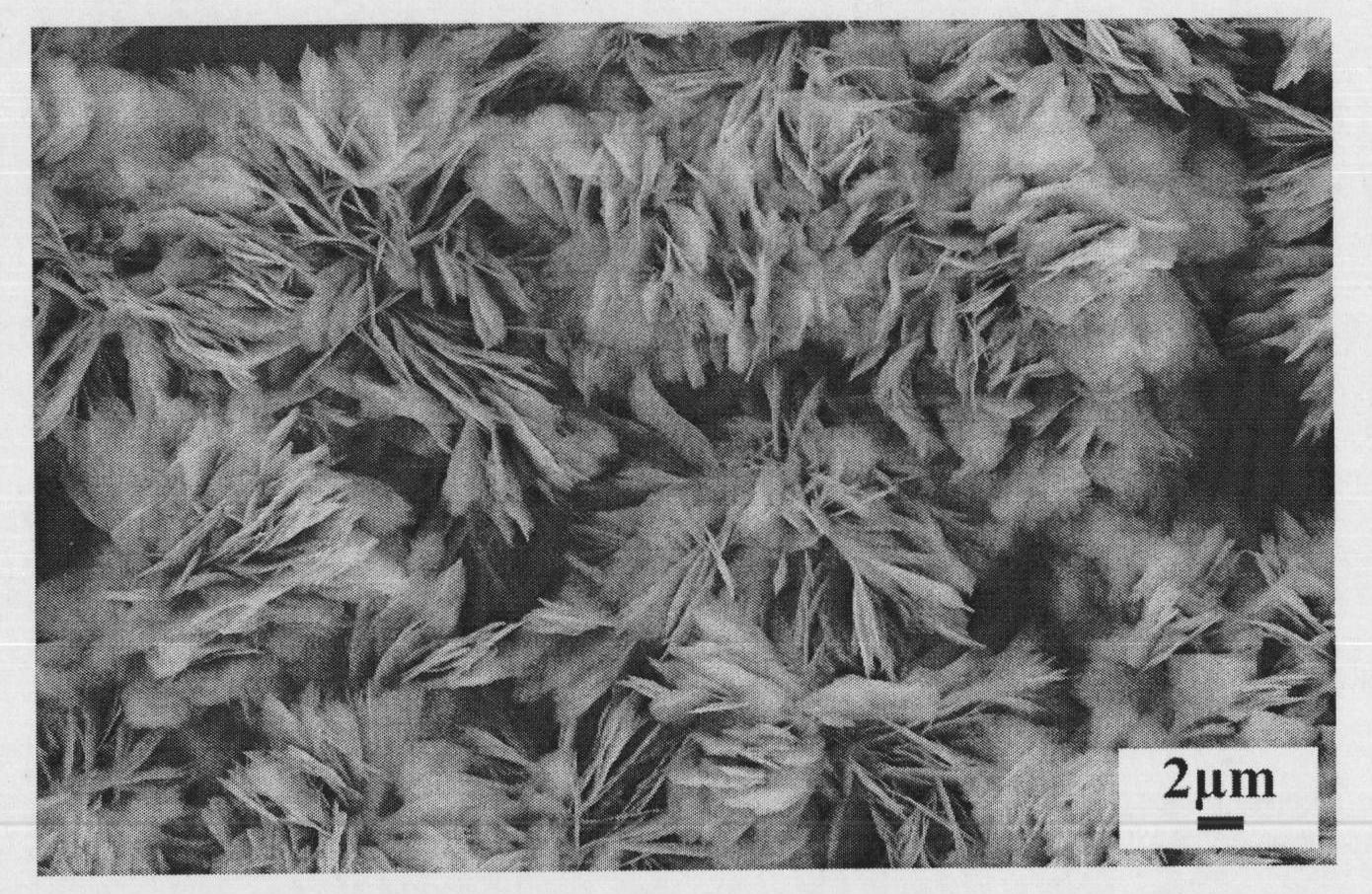

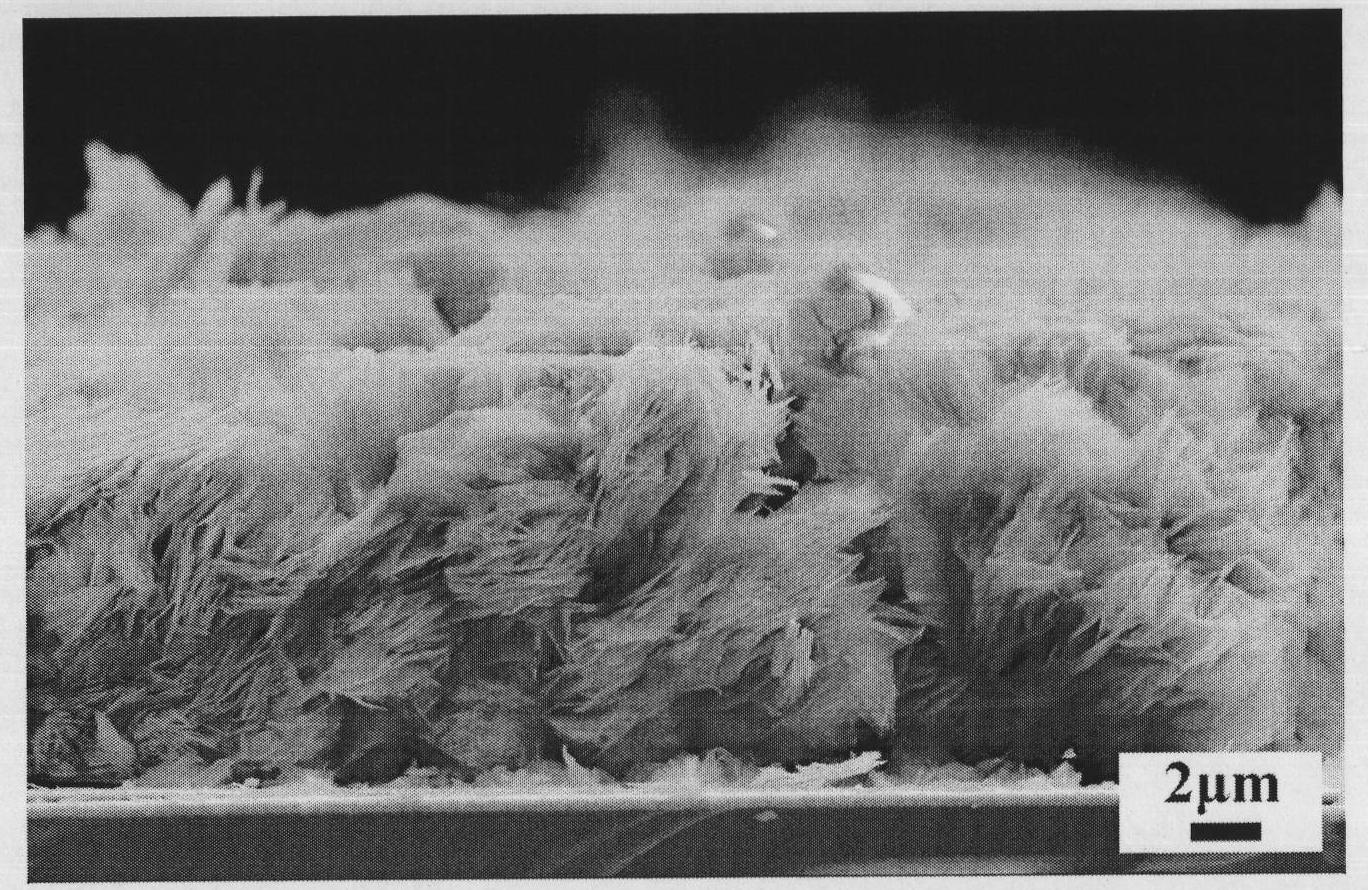

Image

Examples

Embodiment Construction

[0017] Below in conjunction with example technical scheme of the present invention is further described:

[0018] 1. Dissolve equimolar amounts of chemically pure zinc nitrate hexahydrate and hexamethylenetetramine in a 1L volumetric flask with ionized water to prepare a reaction solution with a molar concentration of 0.05mol / L. It was then ultrasonically treated for 1 hour and then removed for use.

[0019] 2. Divide the area of 5 pieces into 2cm 2 The FTO conductive glass loaded with a 200nm thick ZnO thin film was used as a growth substrate, which was first cleaned with acetone, absolute ethanol and deionized water, and finally dried. Put the above-mentioned treated substrate into a reaction kettle with a polytetrafluoroethylene liner, inject the reaction solution prepared in the first step, and keep the temperature at 95°C for 24 hours, and then keep it at 60°C for 48 hours , and finally stood at 25°C for 10 hours.

[0020] 3. After the reaction is over, take out the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com