A kind of production system of environment-friendly gold ore beneficiation agent

A technology for a gold ore dressing agent and a production system, which is applied in the field of metal smelting production equipment, can solve problems such as the inability to meet the continuous and efficient production of environmentally friendly gold ore dressing agents, and achieve the effects of reducing pollution and damage, large output and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

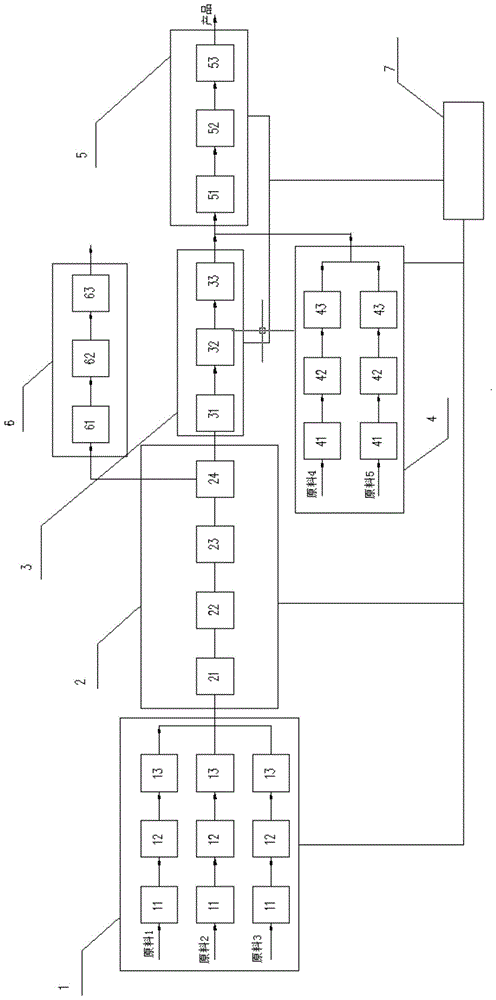

[0028] A kind of production system of environment-friendly gold ore dressing agent of the present invention, as figure 1 As shown, it includes a batching device 1 connected in sequence, a mixing reaction device 2, a cooling and solidification device 3, a secondary batching device 4 and a finished product packaging device 5, the mixing reaction device is also connected with the tail gas treatment device 6, and the automatic control system 7 is connected with the The primary batching device 1, the mixing reaction device 2, the cooling and solidification device 3, the secondary batching device 4, the finished product packaging device 5 and the tail gas treatment device 6 are connected.

[0029] The primary batching device 1 includes 3 hoppers A11, 3 belt conveyors A12 and 3 hopper scales A13, each hopper A11 is connected with a belt conveyor A12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com