Device for detecting eccentric part diameter of machine element in course of gold processing on grinding machine

An eccentric, equipment technology used in metalworking equipment, mechanical diameter measurement, grinding machine parts, etc., to solve problems such as lost time, slow detection and processing operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

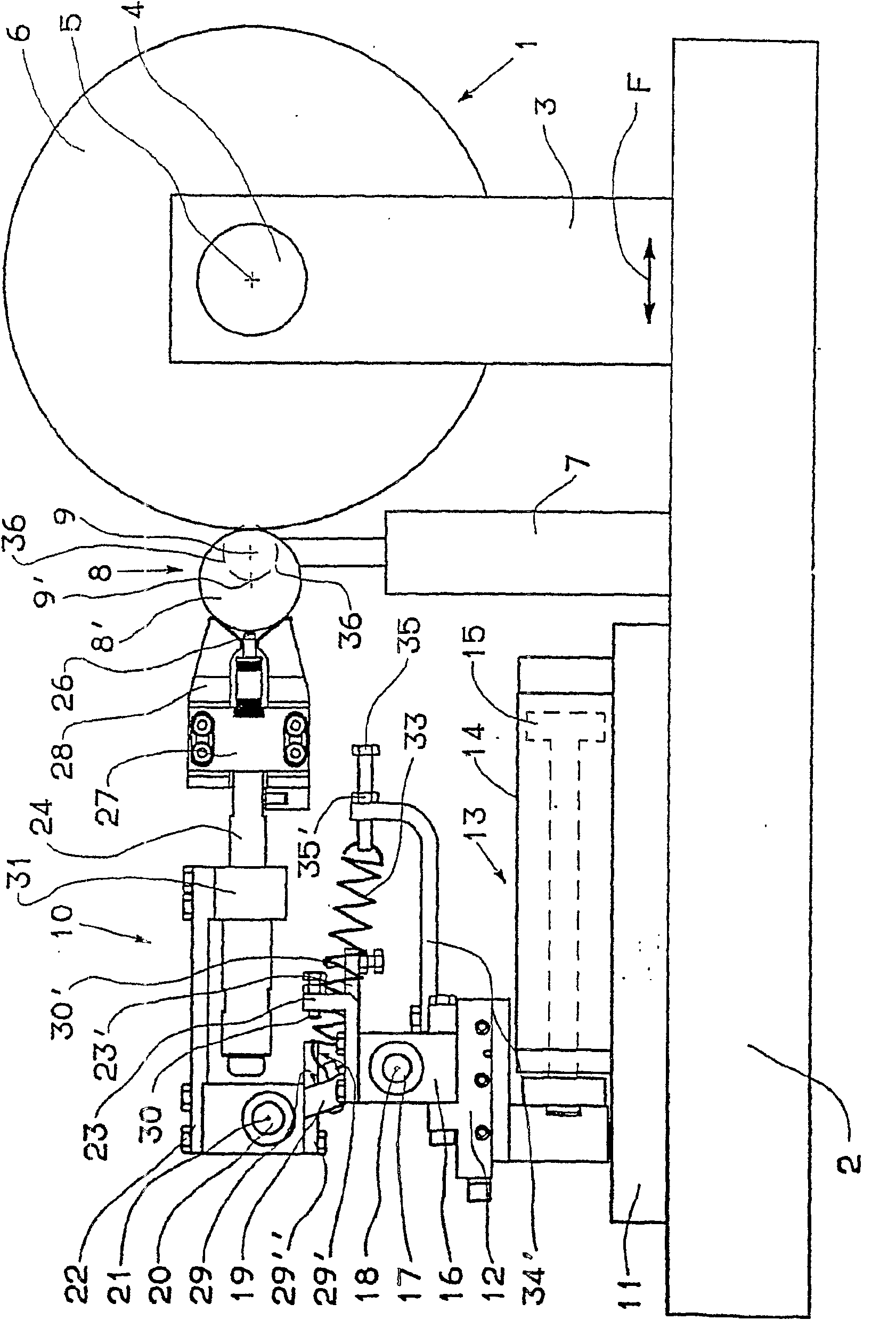

[0016] Now refer to image 3 A computer numerically controlled ("CNC") grinding machine 1 includes a bed 2 to which is attached a grinding wheel carriage 3 for supporting a spindle 4 defining an axis 5 of rotation of a grinding wheel 6. The grinding wheel carriage 3 can be moved along with respect to the bed 2 in a well-known manner. image 3 Move in the direction of the arrow F shown.

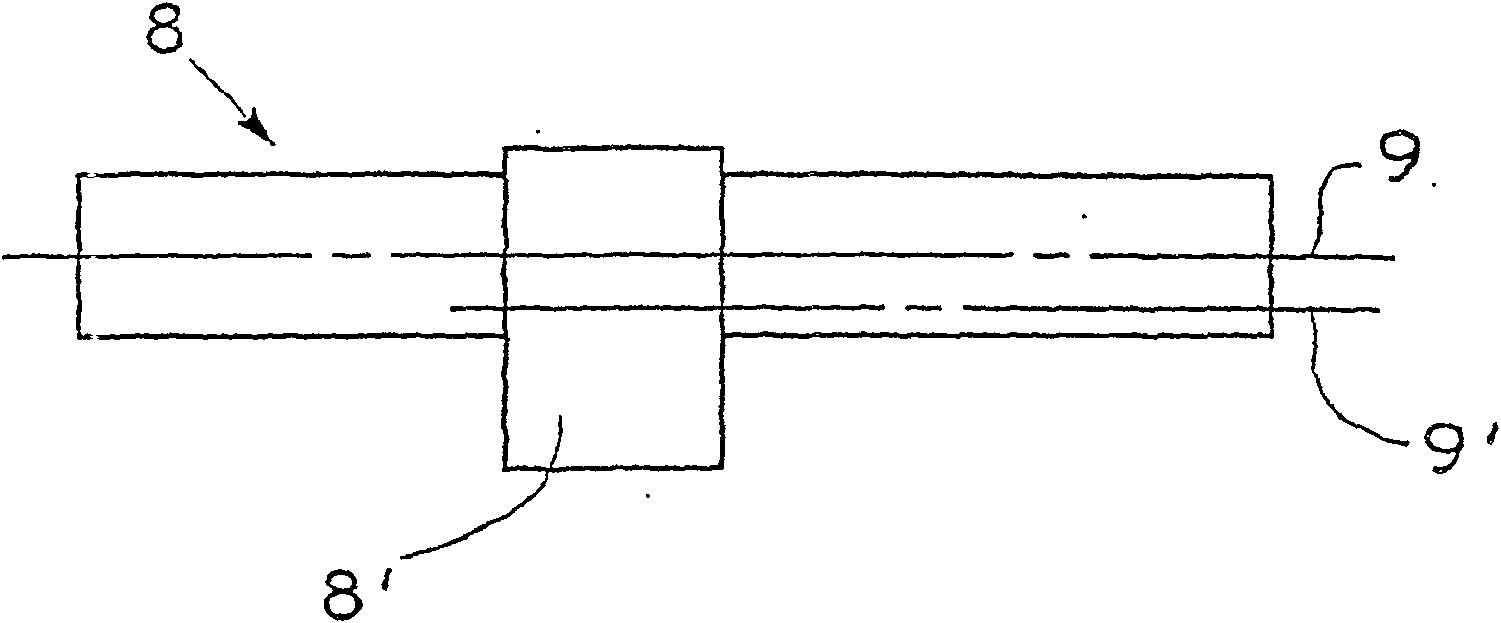

[0017] A table 7 carrying the workpiece to be inspected (for example, the shaft 8 of a compressor with at least one cylindrical eccentric portion, or pin 8') is attached between a mandrel and an end pin seat (not shown). On the bed 2 between them, they define an axis of rotation 9 that coincides with the main geometric axis of the workpiece 8 . Thus, during the rotation of the workpiece 8, the crank pin 8' performs an eccentric movement about the axis 9.

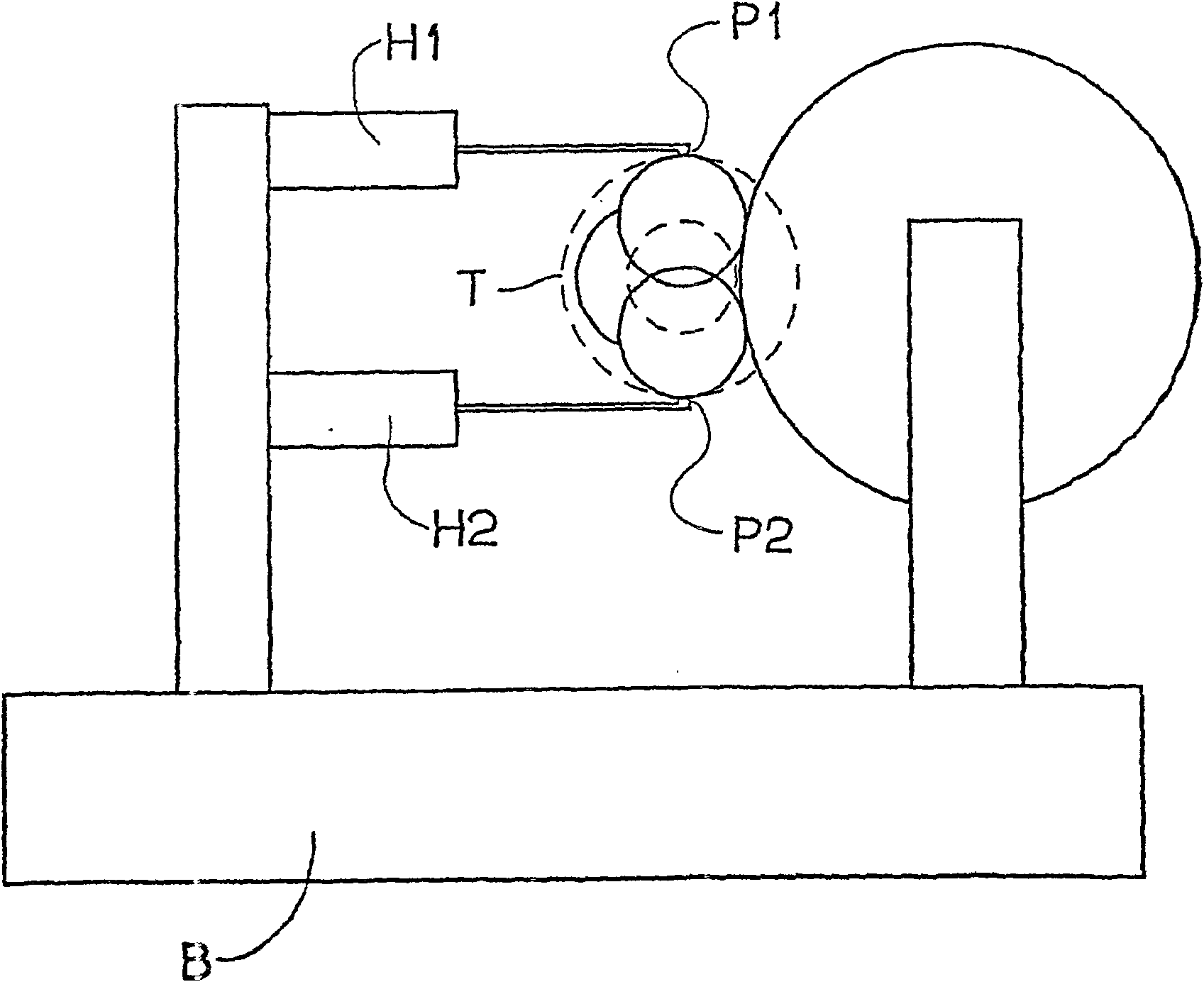

[0018] Furthermore, a device 10 is attached to the bed 2, also shown in Figure 4 and 5 Among them, it is used to check the diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com