Manufacturing method for high-precision cold-drawing welded pipe

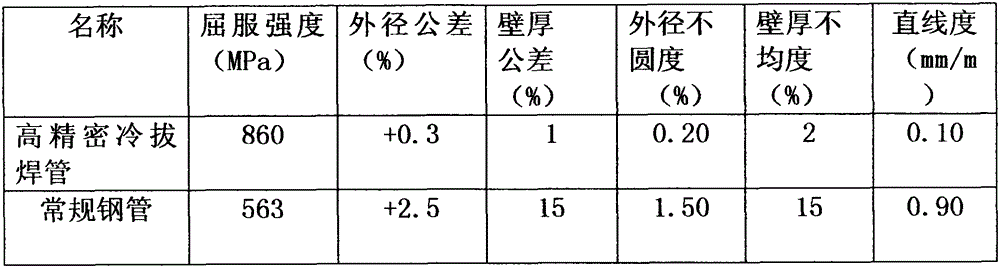

A manufacturing method and high-precision technology, applied in the field of manufacturing high-precision cold-drawn welded pipes, can solve the problems of low precision of welded pipes, slow production speed, and large energy waste, so as to improve deburring speed, fast processing and forming speed, and improve production speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A manufacturing method of a high-precision cold-drawn welded pipe of the present invention comprises the following steps:

[0034] (1) Slitting: Slitting the wide steel coil made of 27SiMn on the slitting machine, and determining the width of the steel coil after slitting according to the diameter of the welded pipe; for example, the required welded pipe diameter is 100mm, due to the roll forming process Among them, there is a certain elongation in the width direction of the steel coil, and the actual width of the steel coil is calculated according to the elongation, and then slitting is carried out according to this width, and the width should be less than 314mm, which varies according to different forming curves;

[0035](2) Roll bending forming: the steel coil after slitting is placed on the display rack, the end of the steel coil is drawn out by the feeding mechanism, and sent to the continuous pressure roll forming mechanism for roll forming processing...

Embodiment 2

[0057] Embodiment 2: A manufacturing method of a high-precision cold-drawn welded pipe of the present invention comprises the following steps:

[0058] (1) Slitting: Slitting a wide steel coil made of 27SiMn on a slitting machine, and determining the width of the steel coil after slitting according to the diameter of the welded pipe; Among them, there is a certain elongation in the width direction of the steel coil, and the actual width of the steel coil is calculated according to the elongation, and then slitting is carried out according to the width, and the width should be less than 628mm, which varies according to the different forming curves;

[0059] (2) Roll bending forming: the steel coil after slitting is placed on the display rack, the end of the steel coil is drawn out by the feeding mechanism, and sent to the continuous pressure roll forming mechanism for roll forming processing. The roll forming mechanism includes a plurality of continuous sets of pressure roller ...

Embodiment 3

[0078] Embodiment 3: A manufacturing method of a high-precision cold-drawn welded pipe of the present invention comprises the following steps:

[0079] (1) Slitting: Slitting a wide steel coil made of 27SiMn on a slitting machine, and determining the width of the steel coil after slitting according to the diameter of the welded pipe; Among them, there is a certain elongation in the width direction of the steel coil, and the actual width of the steel coil is calculated according to the elongation rate, and then the slitting is carried out according to the width, and the width should be less than 471mm, which varies according to the different forming curves;

[0080] (2) Roll bending forming: the steel coil after slitting is placed on the display rack, the end of the steel coil is drawn out by the feeding mechanism, and sent to the continuous pressure roll forming mechanism for roll forming processing. The roll forming mechanism includes a plurality of continuous sets of pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com