Oil immersion type water proof diving pump

A submersible pump and oil-immersed technology, which is applied in the field of oil-immersed waterproof submersible pumps, can solve the problems of short service life, easy burnout of coils, poor heat dissipation, etc., and achieve the goal of improving service life, prolonging service life and preventing water source pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

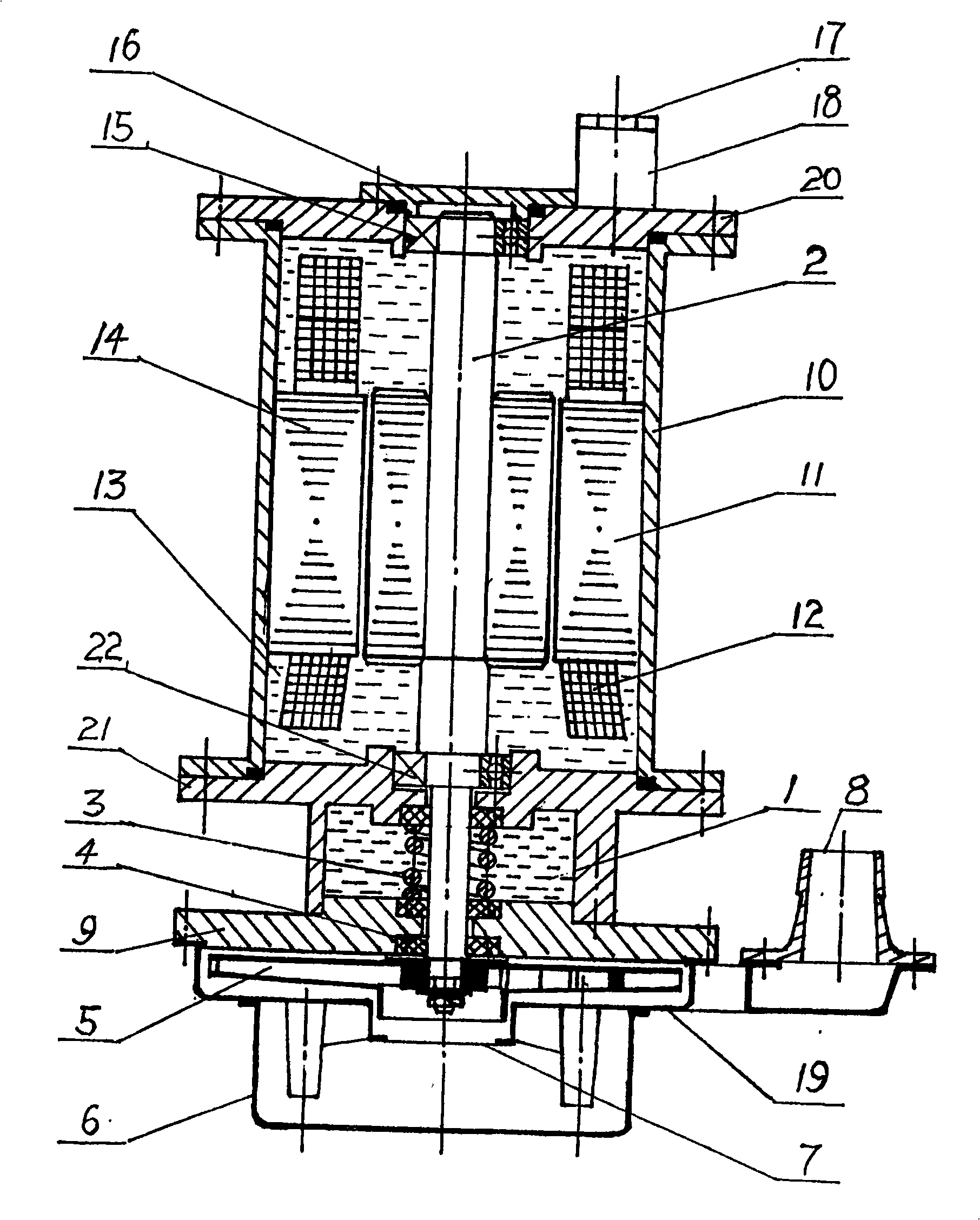

[0007] Embodiment: an oil-immersed waterproof submersible pump, the inner cavity 13 of the submersible motor has a rotor 14 and the stator coil 11 of the waterproof wire coil winding 12, and insulating oil is used as the cooling medium of the inner cavity 13 of the outer shell, and the rear of the motor shaft 2 After installing the rear bearing 15 and the bearing cover 16, the base 20 is equipped with the lead-out line tube 18 for the lead-out line 17, the shell 10, the base 20 and the front cover 21 close the shell inner cavity 13; the middle part of the motor shaft 2 is installed and stuck in the center of the front cover 21 The front bearing 22 and the mechanical seal 3 in the hole, water is the filling of the sealing chamber 1, the submersible pump impeller 5 is installed on the front end of the motor shaft 2, the pump seat 9 is installed on the front end of the sealing chamber 1, and the pump seat 9 is installed on the front end Cover 19, pump cover 19 is provided with wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com