Preparing method of recombined bamboo sectional bar

A bamboo profile and profile technology, which is applied in wood treatment, flat products, impregnated wood, etc., can solve the problems of affecting normal use, long processing time, low production efficiency, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

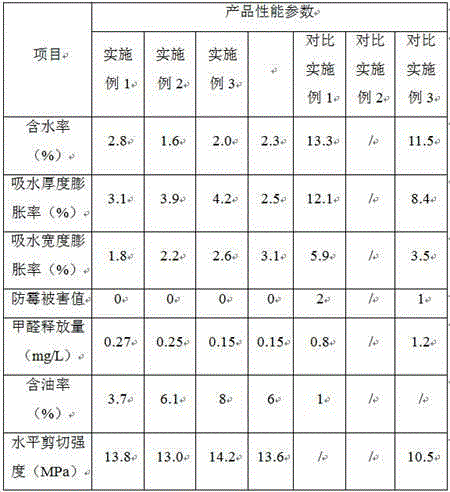

Embodiment 1

[0058] Take the restructuring bamboo profile as an example. First, the bamboo silk is mixed with the thermosetting phenolic adhesive, the solid content of the adhesive is 30%, and the sizing amount is 10% of the quality of the bamboo silk; then the mixed bamboo silk is dried To the moisture content of 2-5%, after cold pressing and curing, into a 22mm thick profile; then inject the alkyl biphenyl type heat transfer oil into the container and heat it to 100°C for heat preservation; then stack the reconstituted bamboo profiles and use The steel belt is fixed so that the vascular bundle of the profile is parallel to the direction of the oil and steam, so that the heat transfer oil surface is higher than the end face of the reconstituted bamboo, so that the reconstituted bamboo profile is immersed and kept for 10 hours; finally, the reconstituted bamboo profile is taken out and left for 10 minutes After the oil on the surface is automatically sucked into the profile, it is placed in ...

Embodiment 2

[0060] Take the restructuring bamboo profile as an example. First, the bamboo silk is mixed with the thermosetting phenolic adhesive by dipping. The solid content of the adhesive is 45%, and the sizing amount is 25% of the quality of the bamboo silk; then the mixed bamboo silk is dried To the moisture content of 25-30%, after cold pressing and curing to form a profile with a thickness of 20mm; then inject the alkyl naphthalene type heat transfer oil into the container and heat it to 300°C for heat preservation; then stack the reconstituted bamboo profiles and use steel The belt is fixed so that the vascular bundle of the profile is parallel to the direction of the oil and steam, so that the heat transfer oil surface is higher than the end surface of the reconstituted bamboo, so that the reconstituted bamboo profile is immersed and kept for 1 hour; finally, the reconstituted bamboo profile is taken out and left for 2 minutes. After the oil on the surface is automatically sucked i...

Embodiment 3

[0062] Take the restructuring bamboo profile as an example. First, the bamboo silk is mixed with the thermosetting melamine adhesive by dipping. The solid content of the adhesive is 35%, and the sizing amount is 20% of the quality of the bamboo silk; then the mixed bamboo silk is dried To the moisture content of 12-17%, after cold pressing and heating to form a 30mm thick profile; then the vegetable oil is heated to 180℃; then the reconstituted bamboo profile is stacked and fixed with a steel belt so that the vascular bundle of the profile is parallel to the direction of the oil and steam , In this form, make the surface of the heat transfer oil higher than the end surface of the reconstituted bamboo, so that the reconstituted bamboo profile is immersed and kept for 5h; finally, the reconstituted bamboo profile is taken out and rested for 6 minutes, and the oil on the surface is automatically sucked into the interior of the profile and then placed in temperature Cool naturally i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com