Oil impregnated bearing of powder metallurgy with ultra-long service life and manufacturing method thereof

An ultra-long-life, powder metallurgy technology, applied in the field of powder metallurgy ultra-long-life oil-impregnated bearings and its manufacturing, can solve the problems that the service life cannot meet more than 30,000 hours, does not meet environmental protection requirements, and the amount of wear is small, and achieves matrix strength. Improves, reduces frictional resistance, and improves wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods are provided, but the protection scope of the present invention is not limited to the following embodiments. .

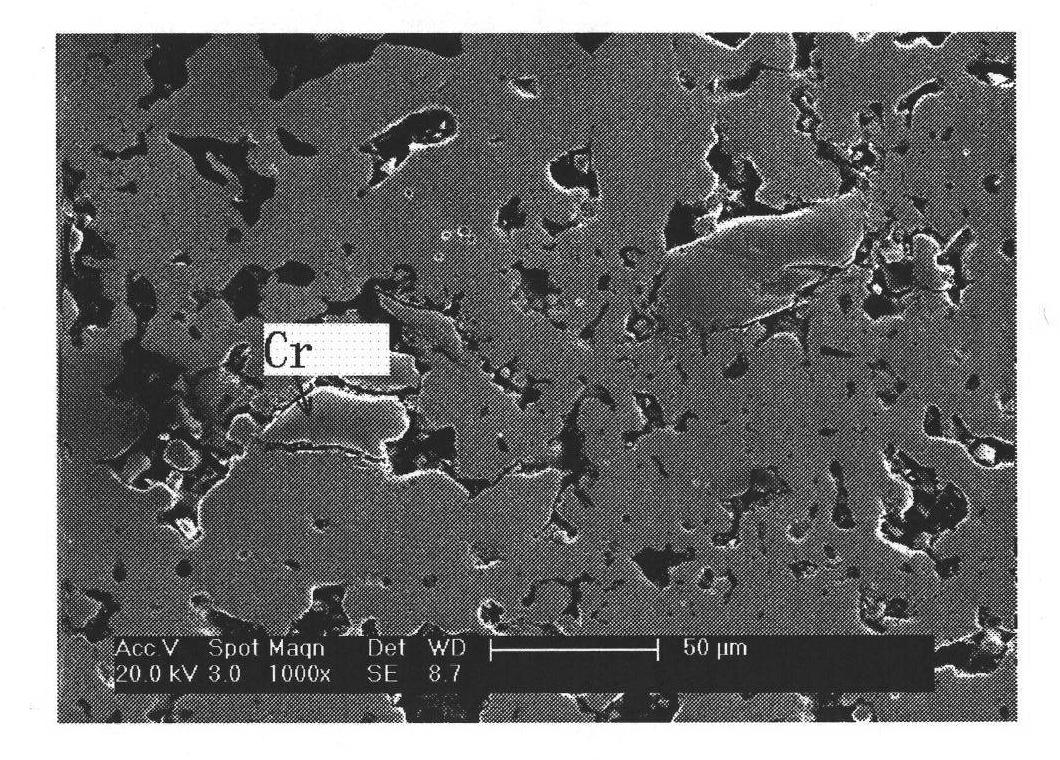

[0019] The powder metallurgy ultra-long-life oil-impregnated bearing of the present invention contains 7-11% of Sn, 0.2-1.0% of P, 2-6% of Cr, and MoS in terms of weight percentage. 2 2-6%, the rest Cu and unavoidable impurities.

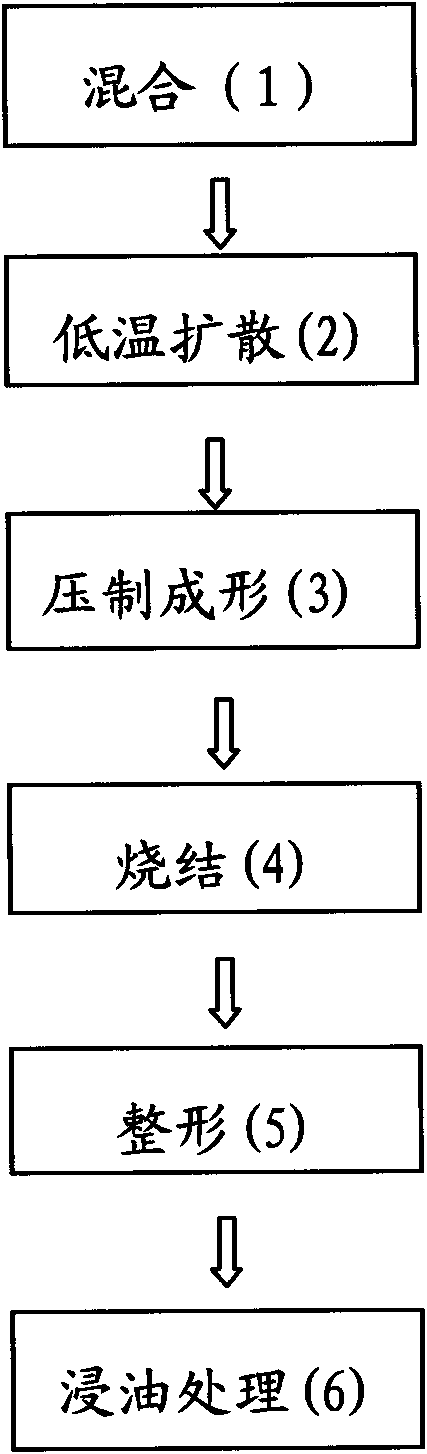

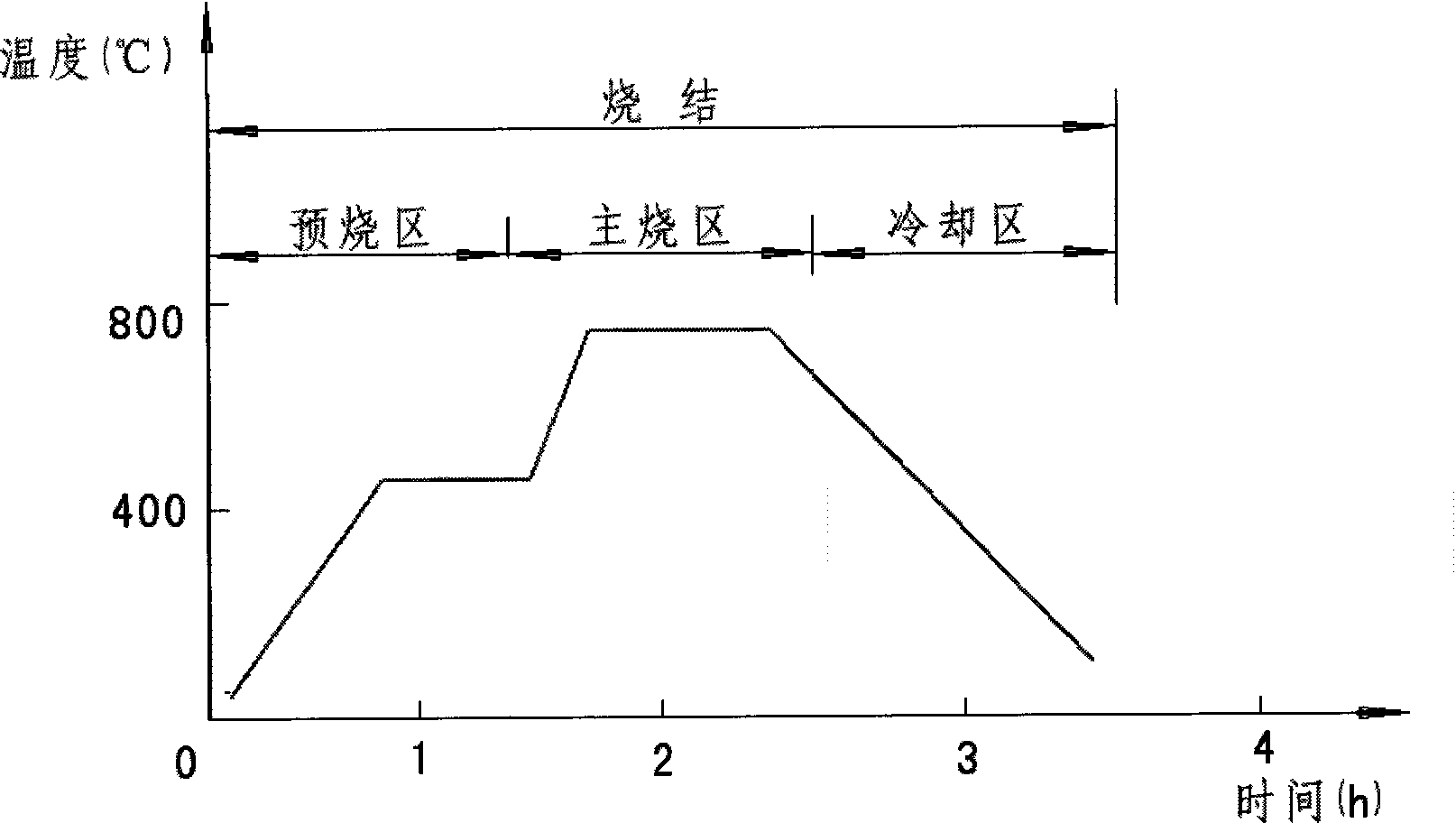

[0020] like figure 1 , 2 Shown, the manufacturing method of powder metallurgy ultra-long life oil-impregnated bearing of the present invention, it adopts to add MoS 2 Powder is used as solid lubricant and phosphorus and chromium are used as strengthening agents of Cu-Sn matrix, which makes Cu-Sn alloy distribution easier to combine at low temperature. After the mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com