Light path structure suitable for femtosecond laser two-photon mirco-nano processing system

A micro-nano processing, femtosecond laser technology, applied in optics, optical components, opto-mechanical equipment, etc., can solve the problem of uneven spatial distribution of light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

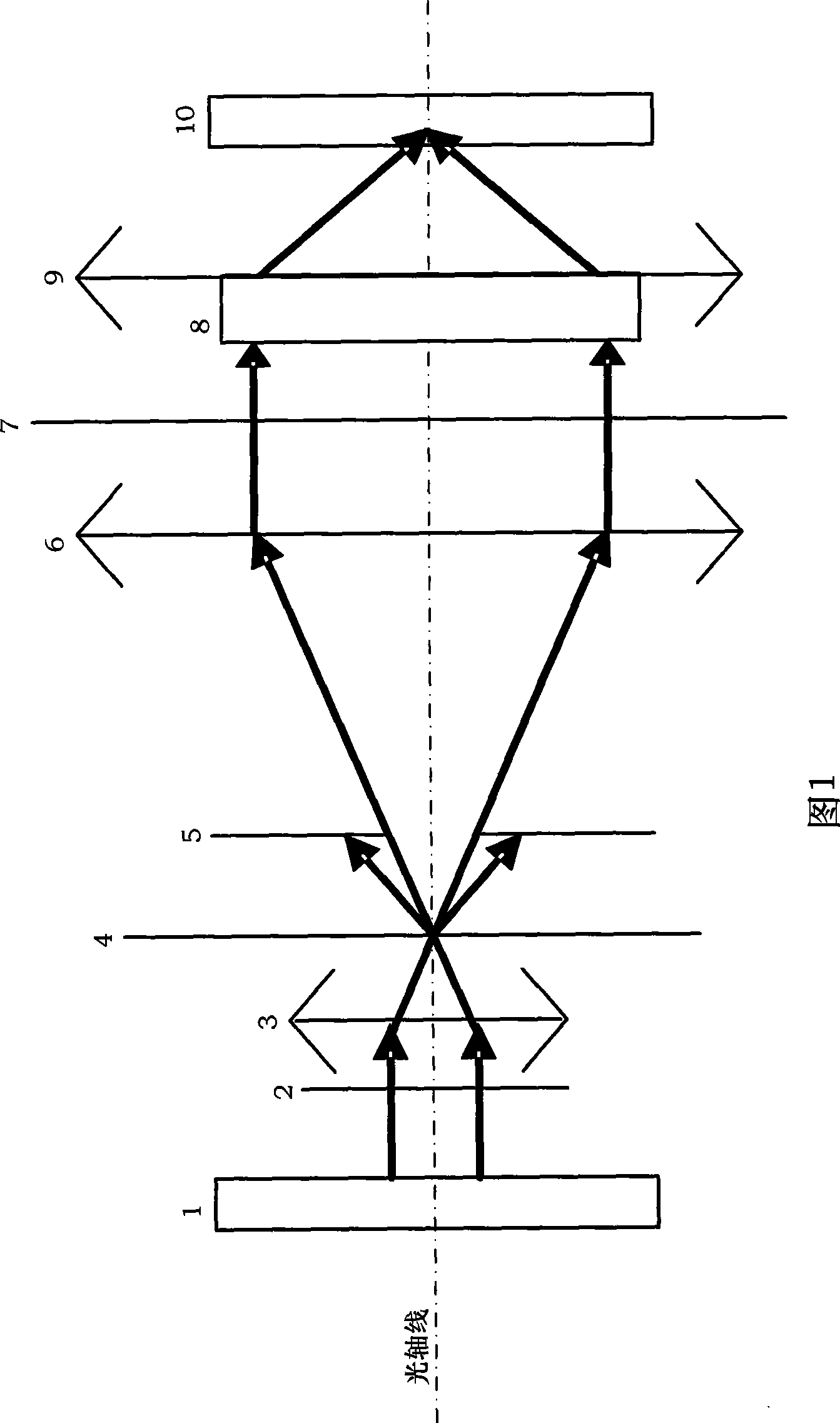

[0019] Referring to Fig. 1, the present invention is an optical path structure applicable to a femtosecond laser two-photon micro-nano processing system. Aperture filter 4, cut-off diaphragm 5, collimating lens 6, aperture diaphragm 7, super-resolution diffractometer 8 and oil immersion objective lens 9 are composed, and the distance between femtosecond two-photon laser 1 and photosensitive resin 10 is centered along the optical axis The sub-arrangement includes an optical gradient attenuator 2, a filtering convex lens 3, a pinhole filter 4, an intercepting diaphragm 5, a collimating lens 6, an aperture diaphragm 7, a super-resolution diffracting device 8, and an oil immersion objective lens 9. The super-resolution diffractometer 8 is installed on the oil immersion objective lens 9 .

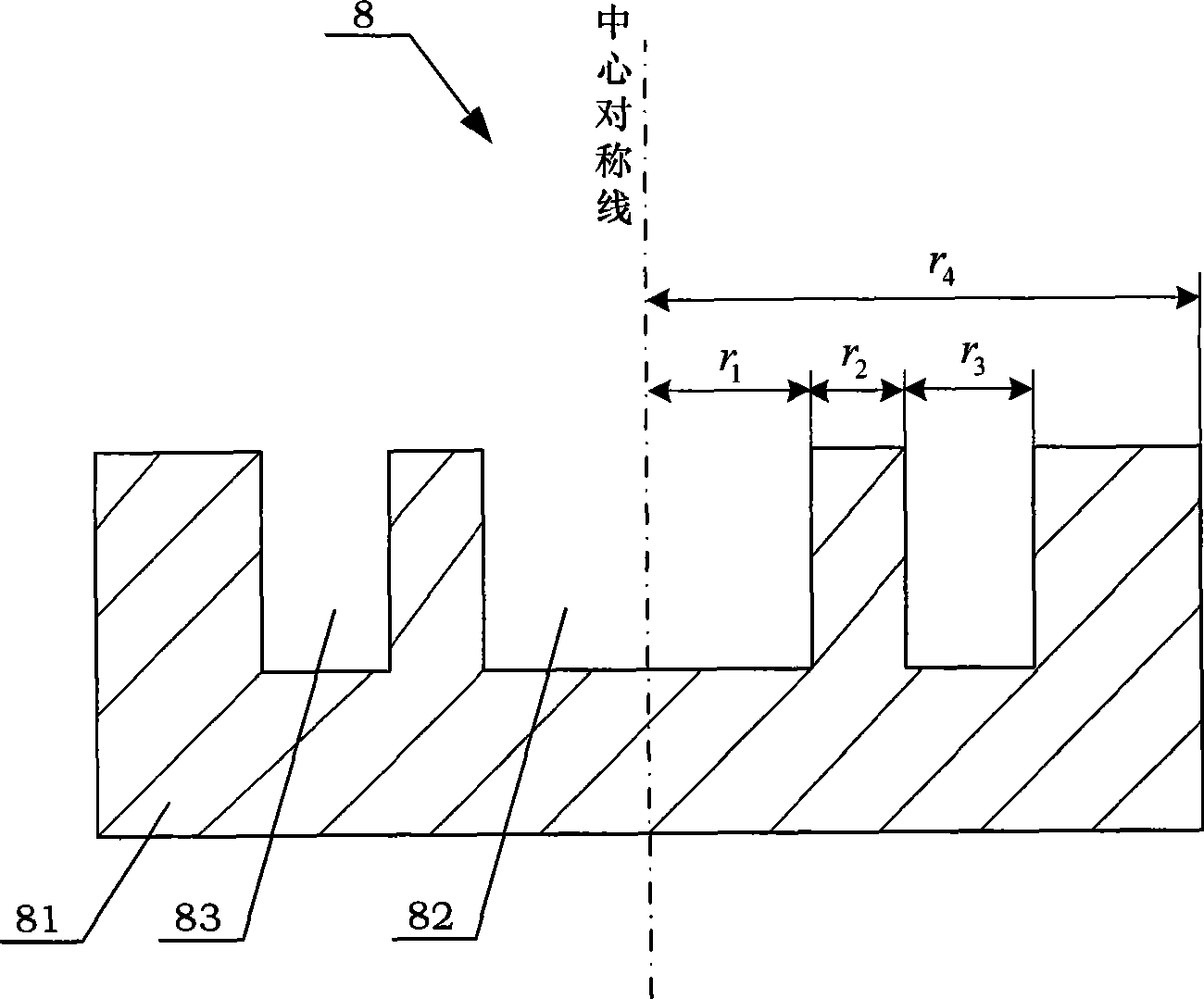

[0020] see image 3 As shown, the super-resolution diffraction device 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com