Antirust method for cold drawing production of high-strength alloy welding wire

A high-strength alloy and welding wire technology, applied in welding medium, welding equipment, metal processing equipment, etc., can solve the problems of high maintenance cost of annealing equipment, inconvenient transportation, and long welding wire cycle, so as to speed up the annealing production cycle and reduce production costs , Solve the effect of easy rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

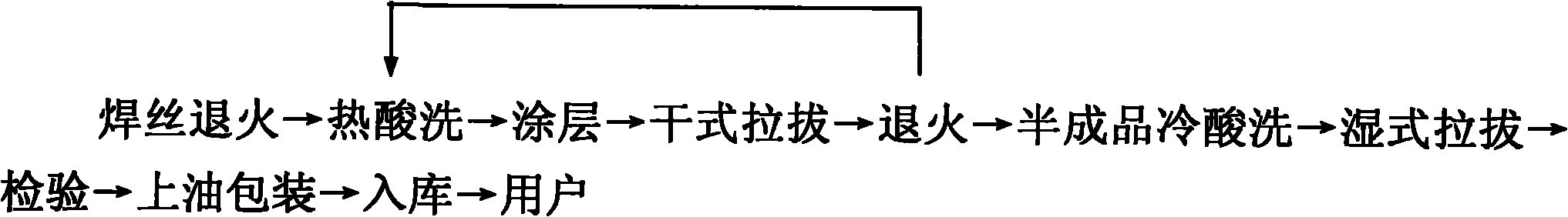

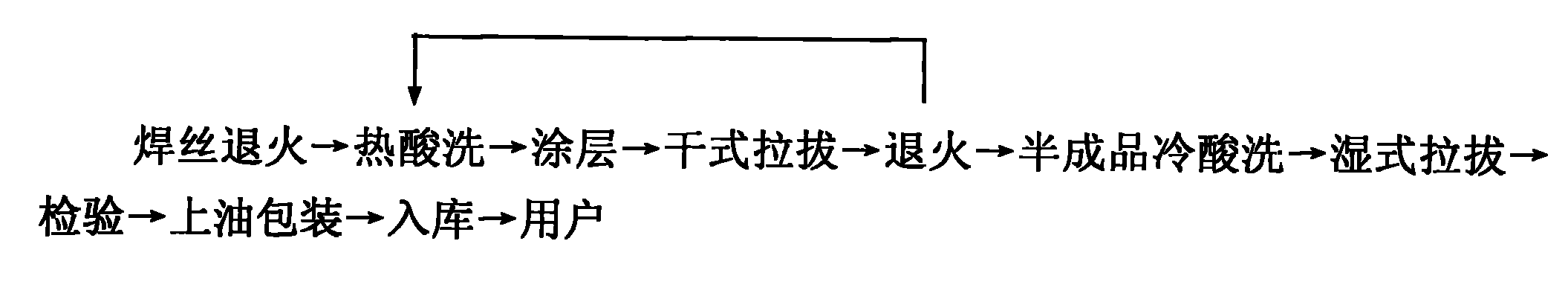

[0040] see figure 1 , the production process of the present invention.

[0041] Preparation of materials: raw material preparation→vacuum induction furnace→finishing→vacuum consumable furnace→turning→forging billet→flaw detection→hot-rolled welding wire→and then cold drawing processing.

[0042] The prepared H10SiMnCrNiMoV and H20SiMnCrNiMoV alloy welding wires, the chemical compositions of the two materials are shown in Table 1, and their compositions meet the requirements of technical standards.

[0043] Table 1 Chemical composition of alloy welding wire materials

[0044] Material

steel type

C

mn

S

P

Si

Ni

Cr

Mo

V

Al

Cu

1#

H10SiMnCr

NiM

0.09

1.03

0.002

0.004

1.27

1.94

1.53

0.53

0.08

0.01

0

2#

H20SiMnCr

NeMV

0.19

1.02

0.002

0.004

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com