High-performance iron-based powder metallurgy oil-containing self-lubricating bearing and production process thereof

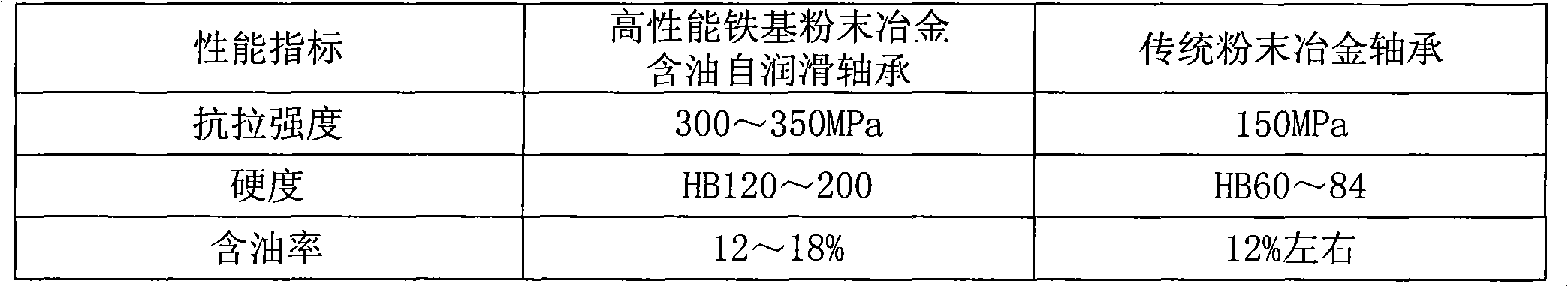

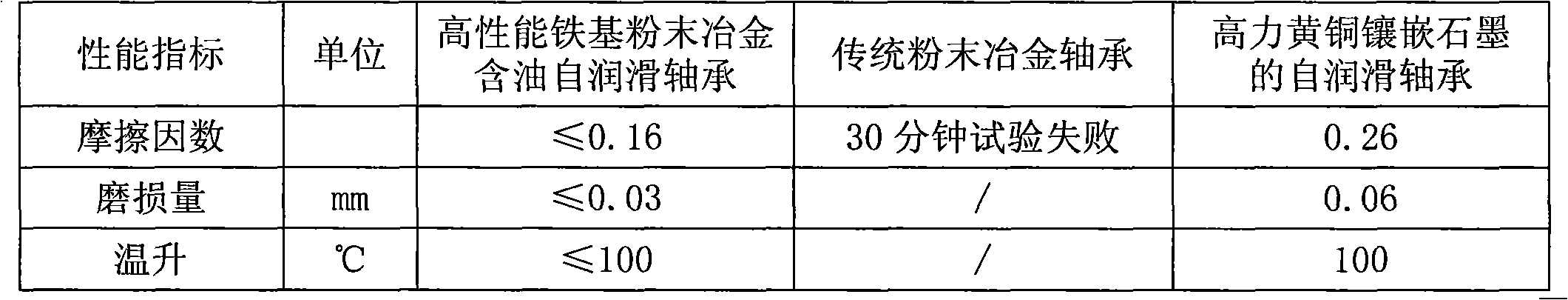

An iron-based powder metallurgy, self-lubricating bearing technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of low crushing strength, reduced bearing capacity, insufficient self-lubrication, etc., to improve impact resistance. , Improve wear resistance and solve the effect of brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

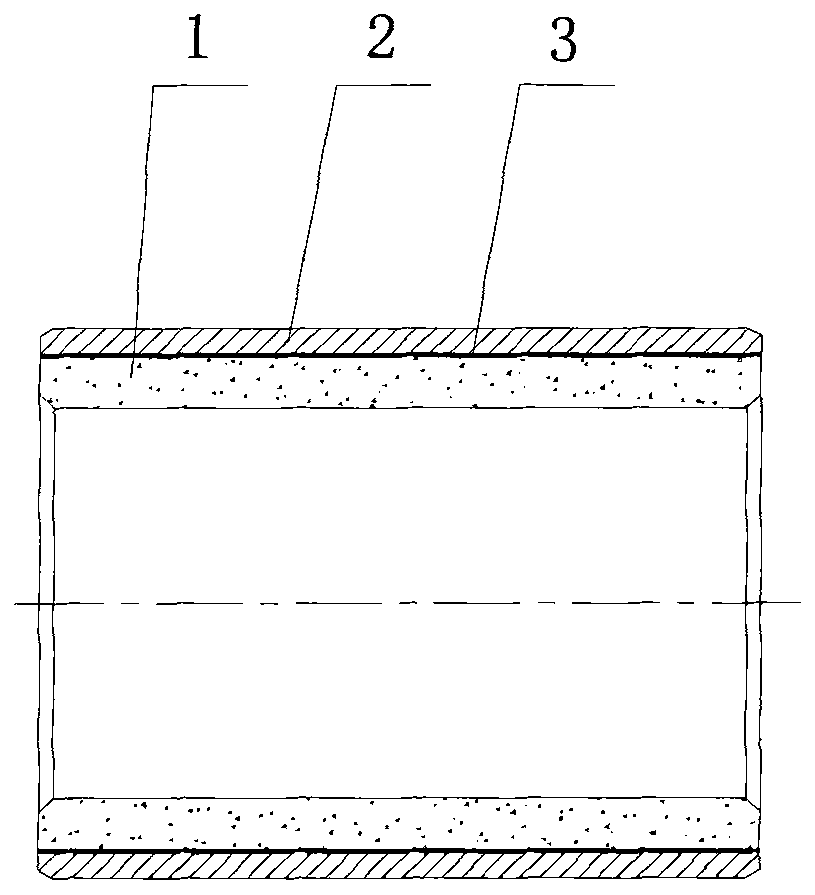

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below by way of examples.

[0020] The high-performance iron-based powder metallurgy oil-containing self-lubricating bearing is in the shape of a sleeve, and the mass ratio of its raw materials is: copper powder 18-22%, aluminum powder 1-4.8%, graphite 0.6-1%, hard particles 1% ~5%, zinc stearate 1~5%, and the balance is iron powder. The average particle size of the copper powder is preferably not greater than 75 μm. The average particle size of the aluminum powder is preferably not greater than 150 μm. The average particle size of the graphite is preferably not greater than 75 μm. The average particle diameter of the hard particles is preferably not greater than 2 μm. The average particle diameter of the iron powder is preferably not greater than 150 μm. The hard particles are Fe 2 P, Fe 3 P, FeB, Fe 2 B. Fe 3 One or any combination of B.

[0021] The process route for manufacturing the above-mentioned high-perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com