Building board drilling device

A technology for drilling device and wood board, which is applied in fixed drilling machines, wood processing appliances, bark area/debris/dust/waste removal, etc., and can solve the problems of high labor intensity, difficult to clean, and harm to the health of operators. , to achieve the effect of convenient operation, splash prevention and precise drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

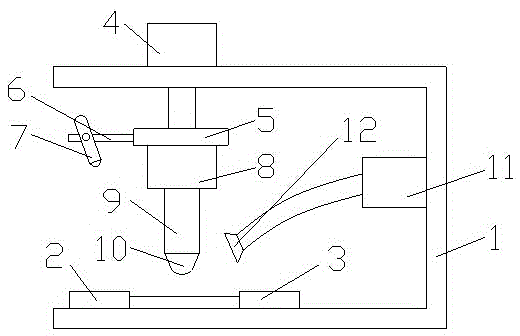

[0011] Reference figure 1 , The invention provides a construction plank drilling device, including a frame 1, a clamping device, a first drive device 4, a support plate 5, a laser sight 7, a second drive device 8, a drill rod 9, a drill bit 10 and The exhaust fan 11; the clamping device includes a left clamping piece 2 and a right clamping piece 3. The left clamping piece 2 and the right clamping piece 3 are slidably arranged on the frame 1, which cooperate with each other to hold the wood to be drilled Fixed, the first driving device 4 is arranged on the frame 1 and above the clamping device. The first driving device 4 can drive the support plate 5 to move up and down. The upper part of the frame 1 is provided with a positioning rod 6 and the laser sight 7 is hinged on On the positioning rod 6, the second driving device 8 is arranged under the support plate 5. The second driving device 8 can drive the drill rod 9 to rotate, and the drill bit 10 is arranged on the drill rod 9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com