Production method of self-extensional polyester fibre

A manufacturing method and self-stretching technology, which is applied in the field of self-stretching polyester manufacturing, can solve the problems of poor process stability, easy occurrence of silk spots, unstable fiber self-stretching performance, etc., and achieve excellent self-stretching performance and process stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

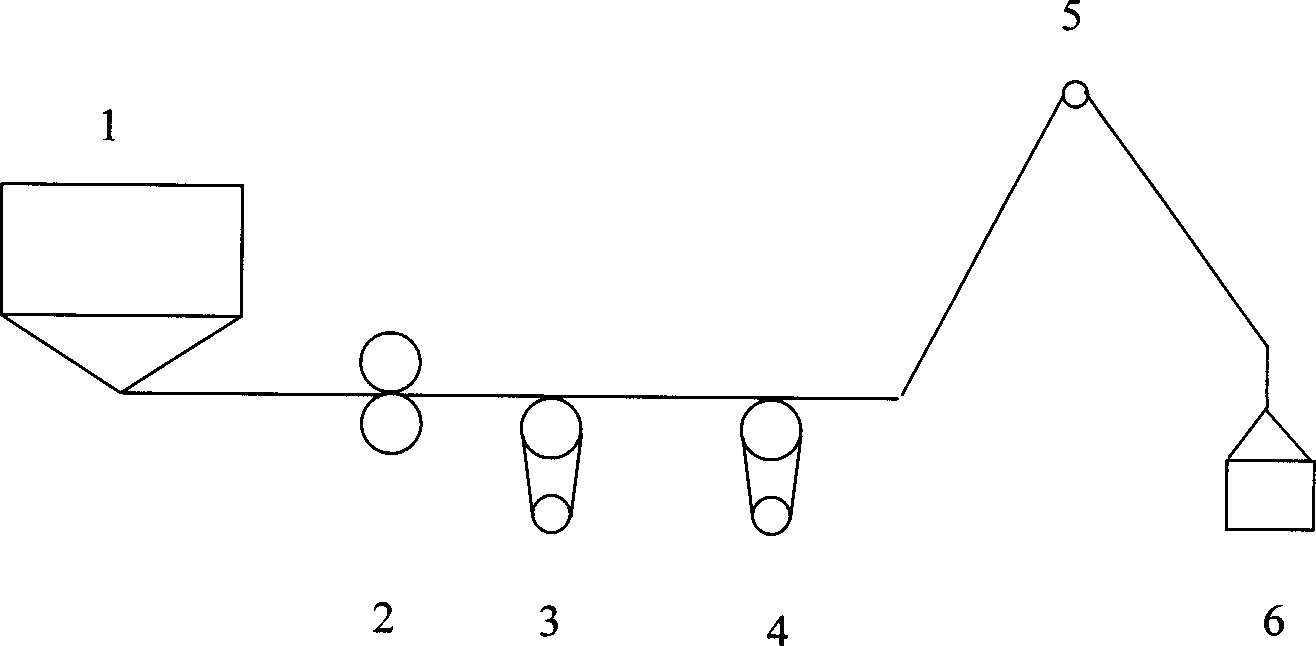

Image

Examples

Embodiment 1

[0020] Polyester (PET) POY raw silk is used as raw material. The POY raw silk is polyester pre-oriented yarn with a spinning speed of 3300m / min, and the specification is 128dtex / 36f. figure 1 The flat drawing machine shown above passes through the wire feeding roller, controls the temperature of the upper hot plate to 90°C, the temperature of the lower hot plate to 130°C, the drafting ratio is 1.01, the heat setting time is 0.25 seconds, the drafting speed is 350m / min, and then the winding is carried out by the small rotor. Get the product. The production is stable, there is no swaying phenomenon, and the coiling is good. After testing, the self-elongation of polyester is 3.21%. The product is stored for 3 months and tested again. The self-elongation rate is 3.2%, and the product performance is stable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com