Top drive cable saddle frame

A cable and saddle technology, which is applied in the field of top drive cable saddle frame, can solve the problems of potential safety hazards and inconvenient use of top drive cable saddle frame, and achieve the effects of reduced workload, reliable fixation and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

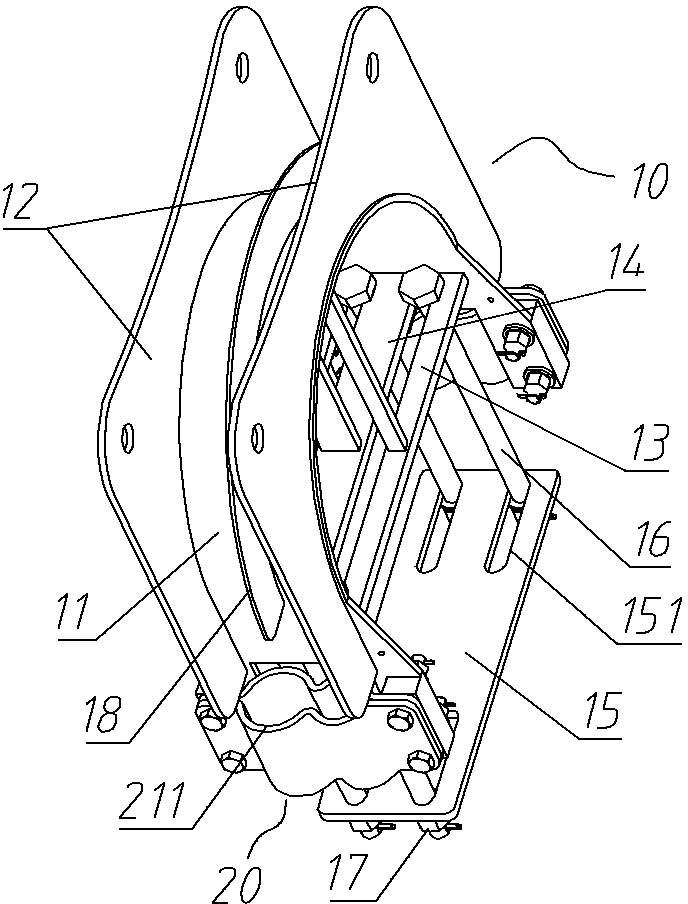

[0025] The present invention will be further described below in conjunction with accompanying drawing.

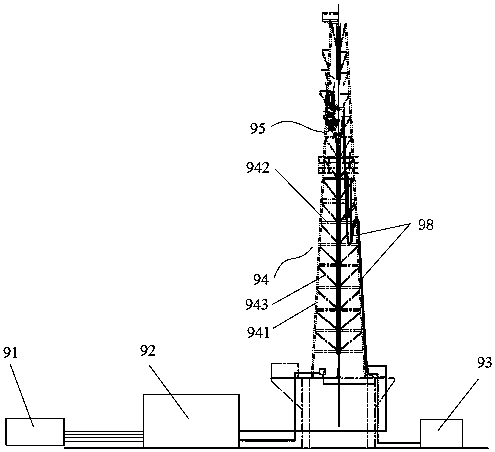

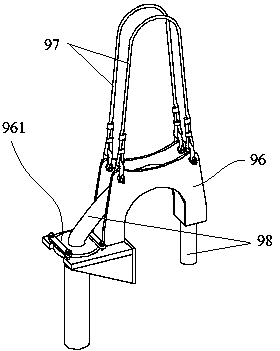

[0026] Embodiment 1 of the top drive cable saddle frame in the present invention is as Figure 3~Figure 6 Shown, comprise arched saddle seat 10, and saddle seat 10 comprises arched arc top plate 11 and is arranged on the cable baffle 12 of the width direction both sides of arc top plate 11, and arc top plate 11 and cable baffle plate 12 are welded Fixed into one body, forming the arched body of the saddle seat 10 .

[0027] A beam support plate 13 is connected between the two bottom ends of the saddle 10 to form a beam support seat for supporting on the upper beam surface of the derrick beam. A crossbeam clamping plate 15 spaced apart from the crossbeam support plate 13 is arranged below the crossbeam support plate 13 for supporting on the upper beam surface of the derrick crossbeam. The top drive cable saddle frame also includes four bolts 16 connected between the crossb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com