A mechanism for lifting and lowering the dust-absorbing furnace cover and an industrial furnace using the mechanism

A furnace cover and dust removal device technology, applied in the direction of furnaces, furnace components, waste heat treatment, etc., can solve the problems that the heat treatment production line cannot be applied, the health of production personnel is unfavorable, and the toxic gas circulation time is long, so as to benefit the health of workers and the exhaustion. Good suction effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

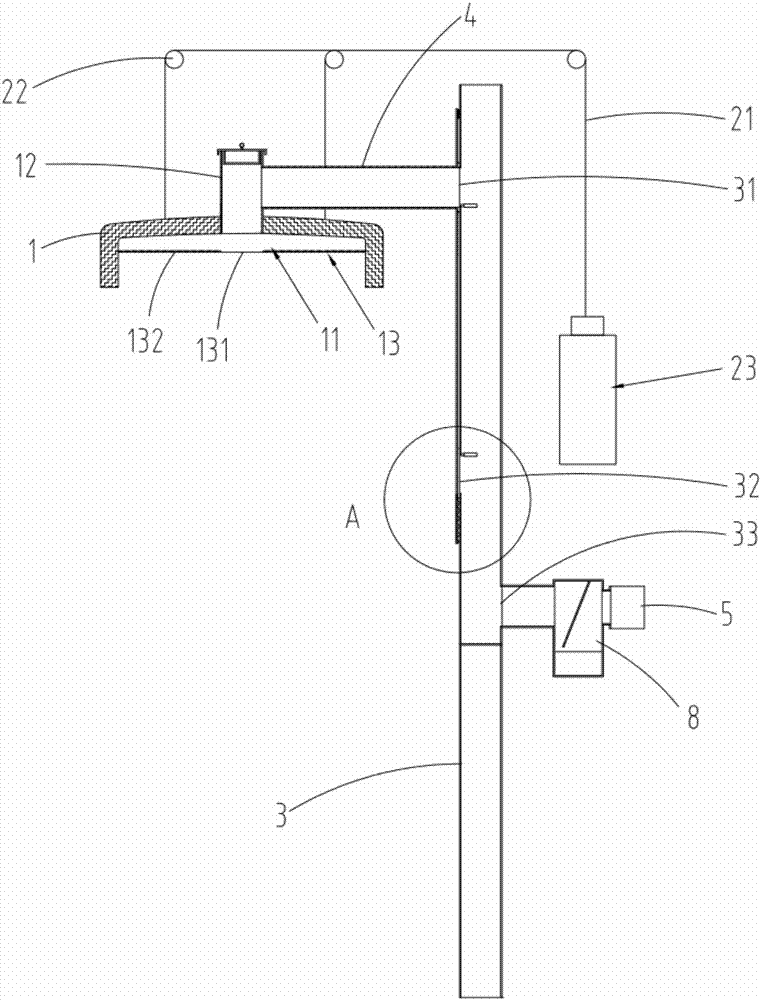

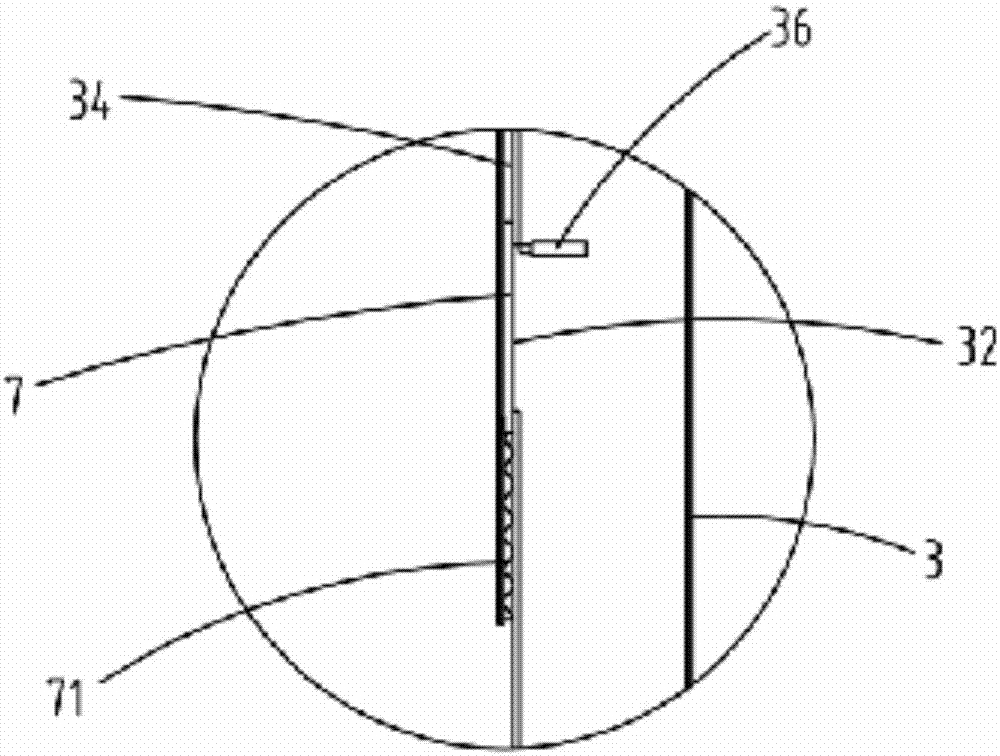

[0032] Such as figure 2 As shown, the present invention provides a lifting and dust-absorbing furnace cover mechanism, including a furnace cover 1 and a lifting mechanism 2 for lifting the furnace cover 1. The inner wall of the furnace cover 1 is formed with a semi-closed cavity 11, and the furnace cover 1 The top is provided with a salt-adding passage 12 communicating with the cavity 11, and the fixed flue gas pipe 3 is provided with a first flue gas inlet 31, a second flue gas inlet 32 and a flue gas outlet 33 communicating with the interior thereof. The gas outlet 33 is connected with a smoking device 5; it also includes a fixed flue gas pipe 3 and a movable flue gas pipe 4 whose end is fixedly connected to the salt adding channel 12, and the end of the movable flue gas pipe 4 can be moved along the outer wall of the fixed flue gas pipe 3 Move up and down, so that when the furnace cover 1 is driven up and down by the lifting mechanism 2, the salt adding channel 12 provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com