A kind of preparation method of cross-linked structure orientation filling reinforced chemical fiber

A technology of cross-linking structure and chemical fiber, which is applied in the direction of melt spinning, conjugated synthetic polymer artificial filament, etc., can solve the problem of clogging spinneret holes, achieve uniform cross-linking, high mechanical properties, and reduce filling defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~18

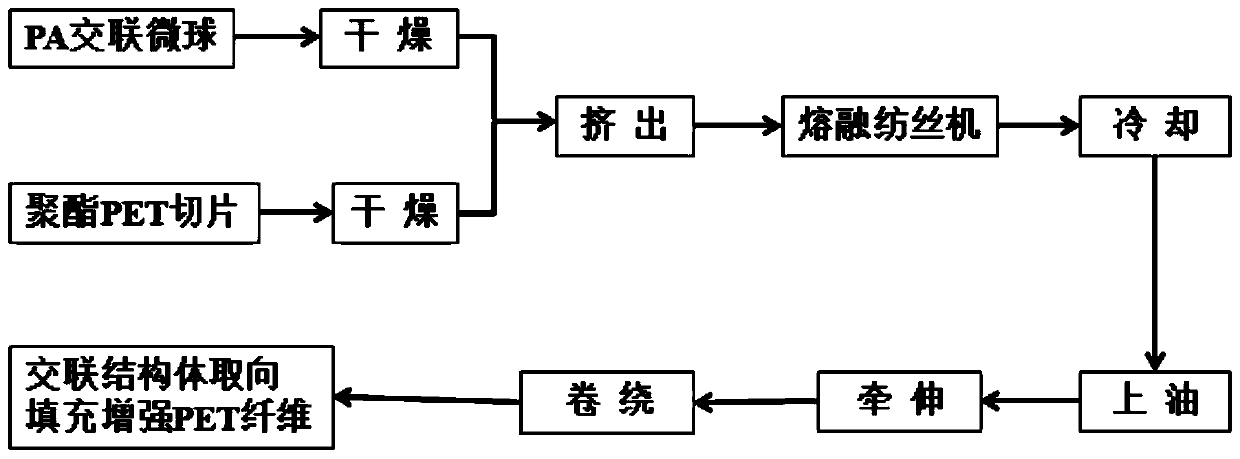

[0059] A preparation method for cross-linked structure orientation reinforced polyester fiber, comprising:

[0060] The main monomer methyl methacrylate (MMA), comonomer butyl acrylate (BA) and styrene (St), cross-linking agent polyethylene glycol dimethacrylate (PEGDMA, number average molecular weight 700-850 ) and the initiator azobisisobutyronitrile are mixed evenly, then add the dispersant magnesium hydroxide (Mg(OH) 2 ) in the water phase of the powder to form an oil-water mixture.

[0061] The above-mentioned oil-water mixture is subjected to high-speed shear homogenization to form a stable microsuspension system, and finally the temperature is raised to polymerize polyacrylate (PAcr) cross-linked microspheres.

[0062] Wherein, shear homogenization condition: shear rate 13000r min -1 , cutting time 7min. Polymerization reaction conditions: Stirring rate 450r·min -1 , temperature 70 ~ 72 ℃, reaction time 10 ~ 12h.

[0063] 100g of polyethylene terephthalate slices (PE...

Embodiment 8

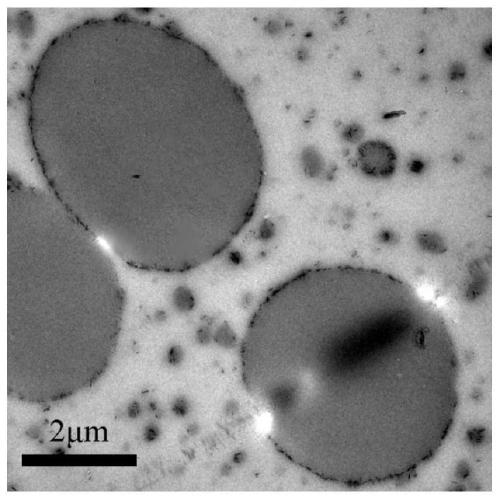

[0082] Typical TEM photo of PAcr cross-linked microspheres in embodiment 8, the black particles are the dispersant not removed on the surface of the microspheres, such as Figure 3a and Figure 3b shown.

Embodiment 1

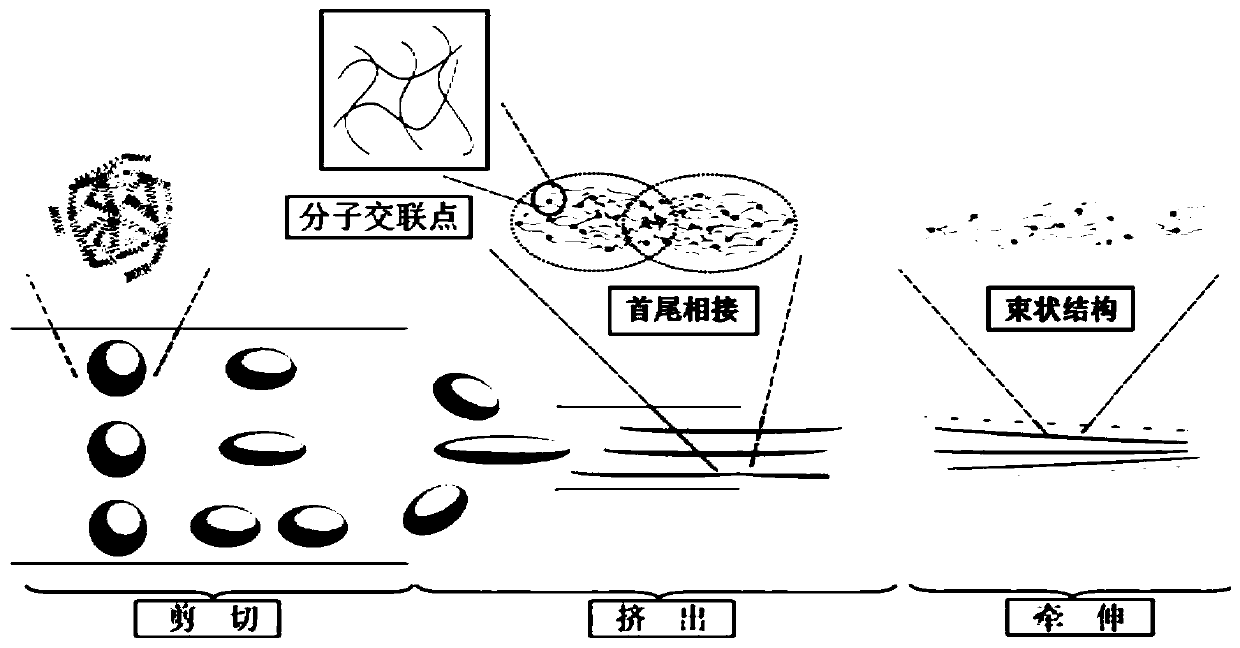

[0083] Composite microsphere dissociation orientation effect (section TEM photo) in the melting shear field in embodiment 1, as Figure 4a and Figure 4b as shown, Figure 4b for Figure 4a Enlarged view inside the dotted box;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| gel rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com