High-modulus high-strength polyvinyl fibre abstraction drafting production line

A high-strength polyethylene, production line technology, applied in the production of complete sets of equipment for artificial threads, single-component polyolefin artificial filaments, filament production, etc., can solve problems such as low drafting ratio, long process route, and low work efficiency , to achieve reasonable process route design, reduce production costs and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

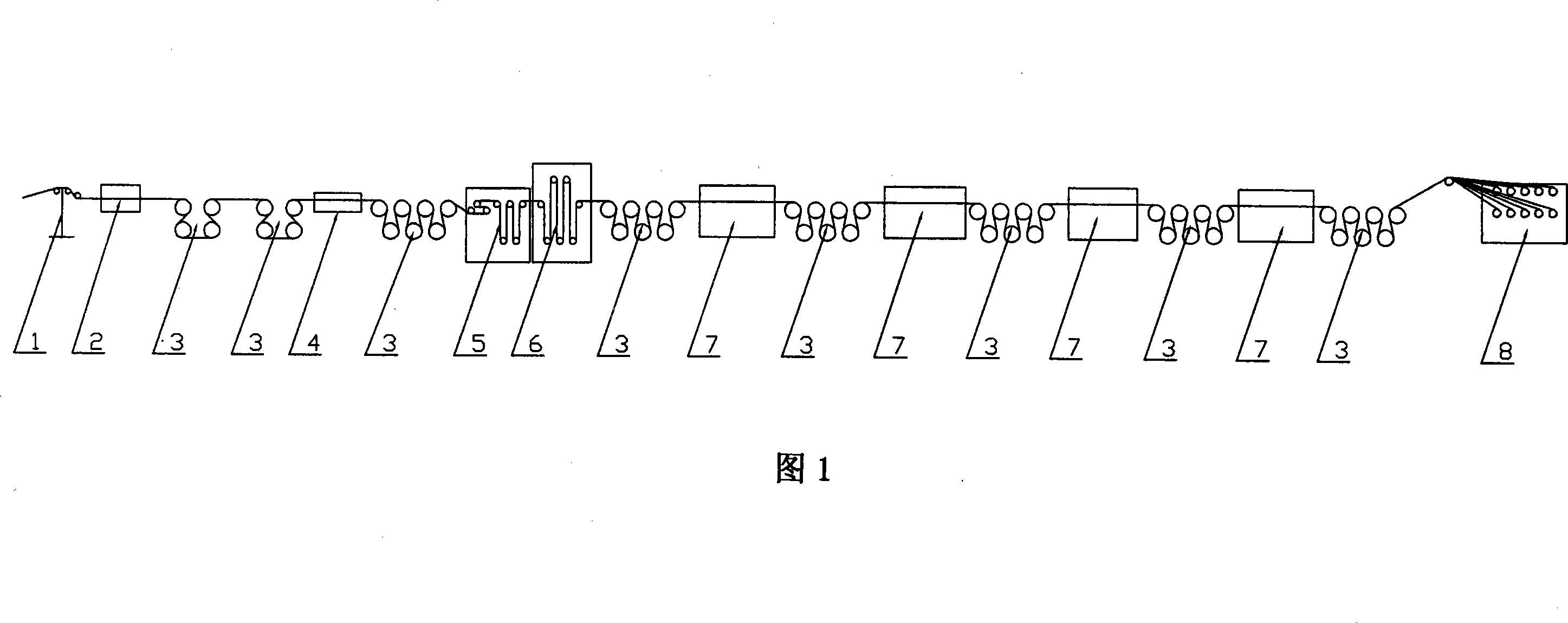

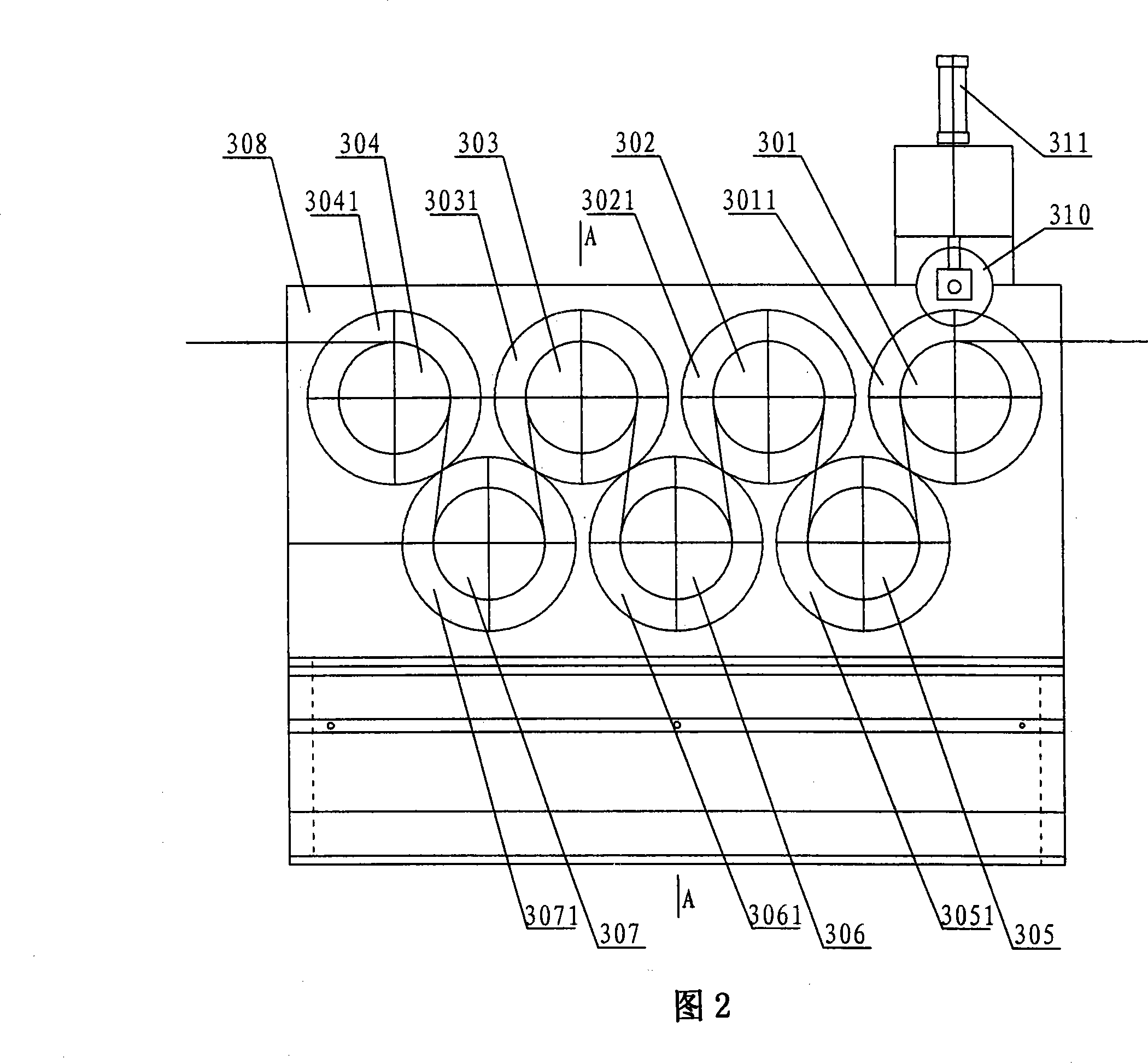

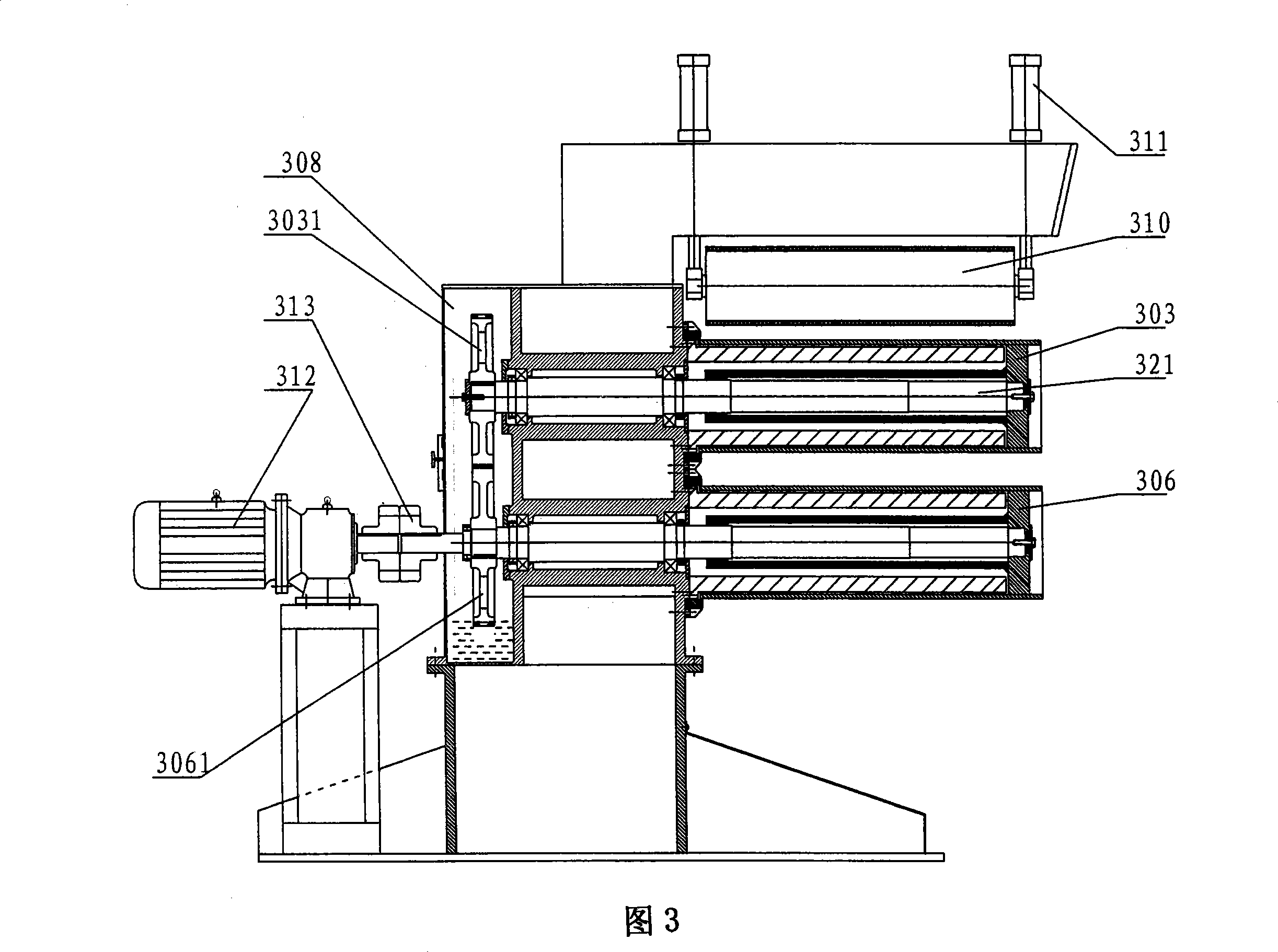

[0033] The production line described in the embodiment of the present invention, as shown in Figure 1, includes: a wire guide frame 1, a constant temperature balancing machine 2, a drafting machine 3, a washing tank 4, an extraction machine 5, a hot air drying box 6, and a drafting hot box 7 and winding machine 8; The wire guide frame 1 is followed by a constant temperature machine 2, two drafting machines 3, a washing tank 4, an extraction machine 5, a hot air drying oven 6, a drafting machine 3, a drafting heat box 7, a drafting machine 3 and a winding machine 8. The above-mentioned drafting heat boxes 7 are four units connected in sequence, and a drafting machine 3 is also connected between every two units.

[0034] During work, the gel fiber processed by the previous sequence enters the constant temperature machine 2 for constant temperature balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com