Mono-LOGO yarn-dyed mini-jacquard fabric

A technology of dobby and yarn-dyed weaving, which is applied in the field of jacquard fabrics and single LOGO yarn-dyed jacquard fabrics. It can solve the problems that have not been properly solved, and achieve the effect of convenient market promotion, high cost performance, and full pattern and color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

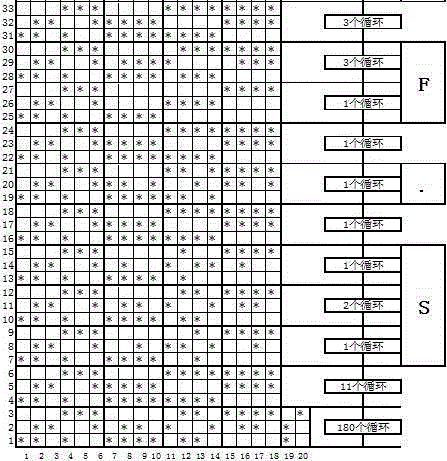

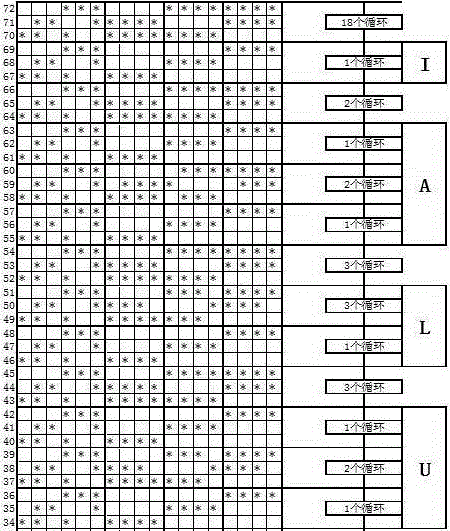

[0014] see figure 1 , figure 2 , a single LOGO yarn-dyed dobby fabric, specifications: warp density 571 threads / 10cm, weft density 244 threads / 10cm, width 106 inches. The warp yarn adopts compact spinning 40S, and the weft yarn adopts copper fiber 32S;

[0015] (1) Pattern design, in order to weave the LOGO letters on the dobby equipment, the pattern is designed in the CAD software and made as follows: figure 1 As shown, the flower type is a single frame, and the cycle of flower positions is equal to the size of the door width;

[0016] (2) Make the pattern, give the pattern in CAD figure 1 Lay weave 2 / 1 and 1 / 2 twill to generate a pattern, and make a machine pattern according to the pattern and the pattern, and the partial pattern is as follows:

[0017] (3) Sizing, sizing is mainly based on starch sizing, adopts the "high concentration, low viscosity" sizing process, adopts constant volume method sizing, TM8010 100kg, phosphate starch 25kg, ADC 25kg, wax flake 3kg, Ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com