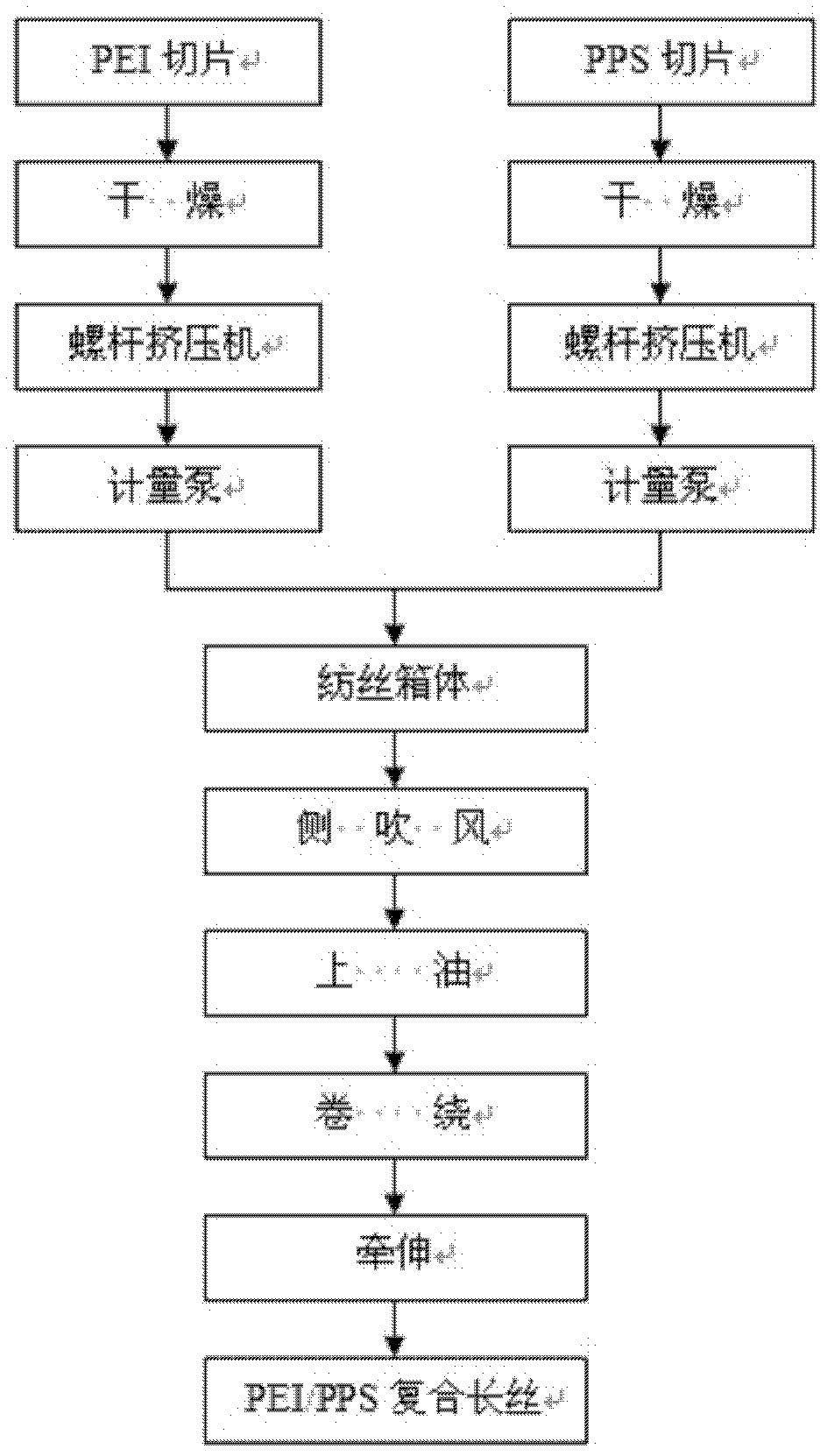

Polyetherimide/polyphenylene sulfide composite filament preparation method

A technology of polyetherimide and polyphenylene sulfide, which is applied in the direction of conjugated synthetic polymer man-made filament, filament/thread forming, stretch spinning, etc., to achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

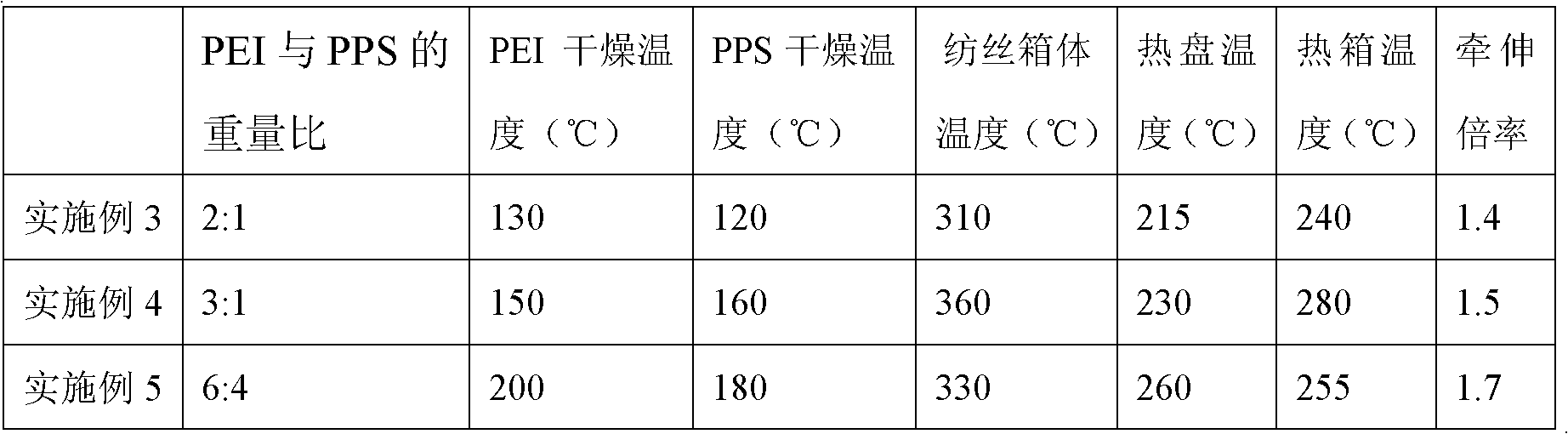

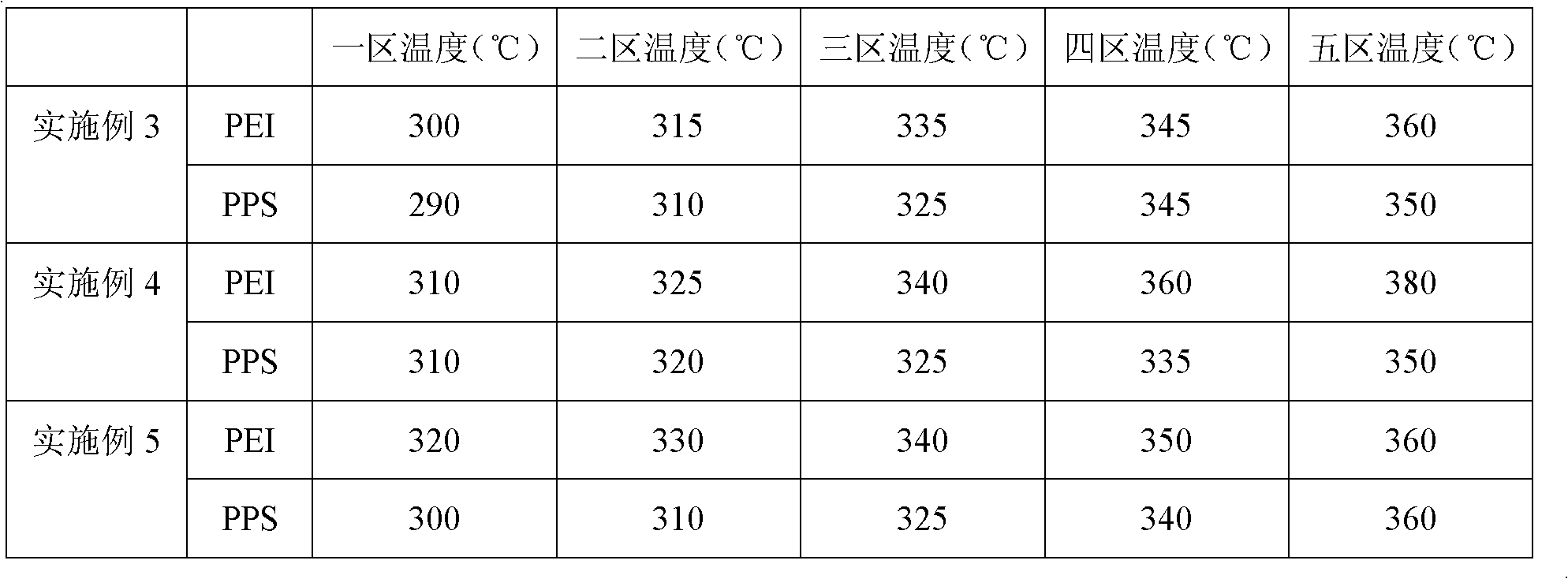

Examples

Embodiment 1

[0023] Example 1: PEI and PPS two raw material slices were dried at 140°C respectively, and then melted and extruded by a screw extruder to form PEI melt and PPS melt; the PEI melt and PPS melt were then Metering through the metering pump respectively; the measured PEI melt and PPS melt are mixed to form a mixed melt, and then extruded from the spinneret hole of the spinning box to form a filamentous melt under the action of the spinning box At this time, the temperature of the spinning box is 340°C; the above-mentioned filamentous melt is extruded from the spinning hole of the spinning box, solidified and formed under the cooling of the side blowing, and then oiled and wound on the winding head. High-speed winding forming, at this time, the speed of the winding head is 3000m / min, and finally after being drawn by the FDF100 parallel drawing machine, PEI / PPS parallel composite filaments are obtained.

[0024] In the above method, the speed of the metering pump for measuring the...

Embodiment 2

[0035] Example 2: PEI and PPS two raw material slices were dried at 160°C and 170°C respectively, and then melted and extruded by a screw extruder to form PEI melt and PPS melt; the PEI melt and The PPS melt is metered through the metering pump respectively; the metered PEI melt and PPS melt are mixed to form a mixed melt, which is extruded from the spinneret hole of the spinning box under the action of the spinning box to form a Filamentous melt, at this time the temperature of the spinning box is 320°C; after the above-mentioned filamentous melt is extruded from the spinning hole of the spinning box, it is solidified and formed under the cooling of side blowing, and then oiled, and High-speed winding forming on the winding head. At this time, the speed of the winding head is 3000m / min. Finally, the above-mentioned composite spinning is drawn by the FDF100 parallel drafting machine to obtain PEI / PPS skin-core composite filaments.

[0036] In the above method, the rotating spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com