Carbon fiber drafting machine

A drafting machine and carbon fiber technology, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of affecting the processing effect, the tension of carbon fibers is not easy, and the equipment occupies a large area, so as to improve convenience, improve processing effect, reduce Effects of length and footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

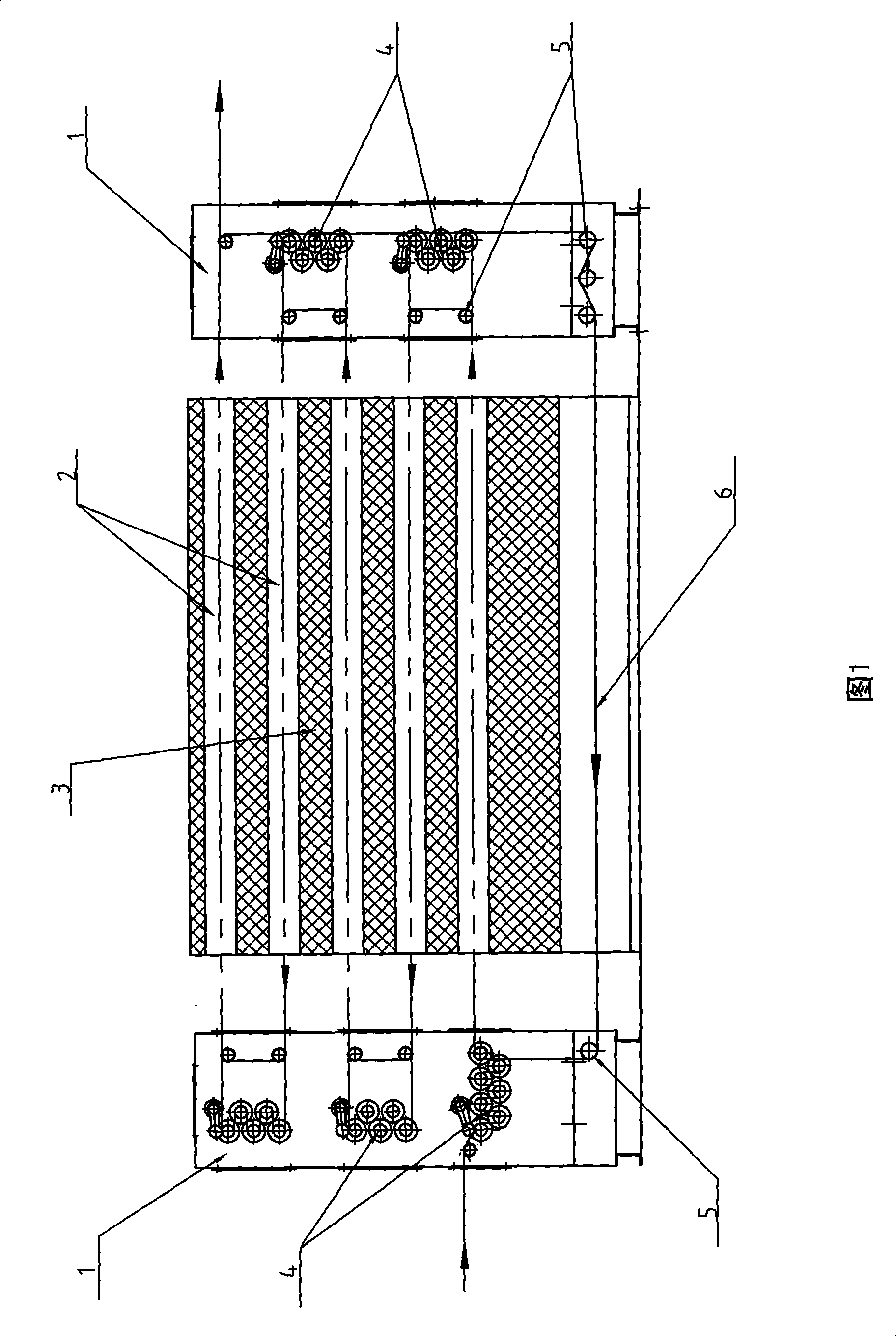

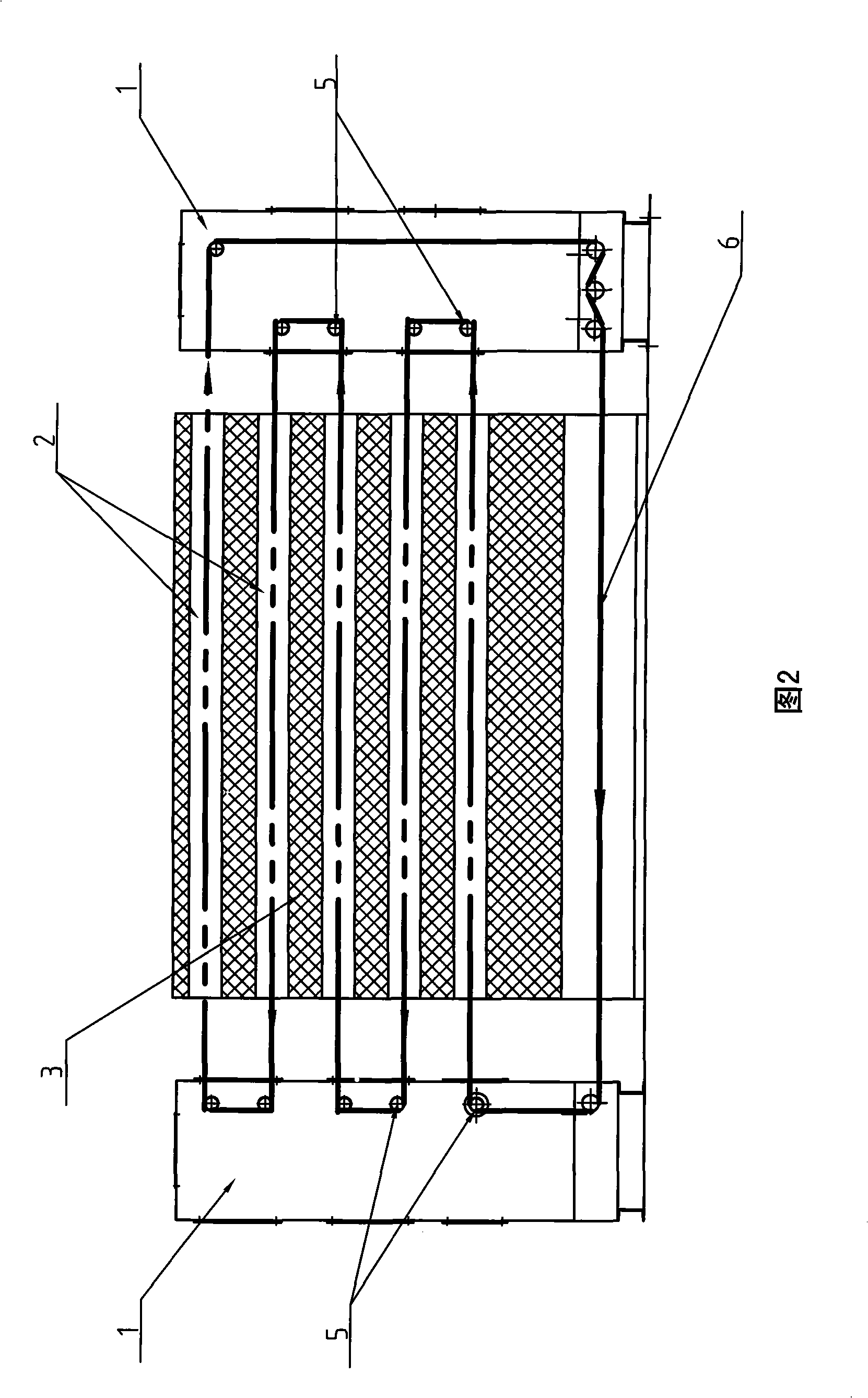

[0009] As shown in Figures 1 and 2, the carbon fiber drafting machine of the present invention includes two drafting units 1, and the two drafting units 1 are respectively arranged on both sides of a pre-oxidation furnace 3 with a multilayer heating channel 2; A drafting unit 1 includes multiple groups of drafting rollers 4 arranged from bottom to top, each group of drafting rollers 4 has its own independent driving device, each group of drafting rollers 4 and the multi-layer heating channel of the pre-oxidation furnace 3 2 correspondingly, so that the carbon fibers can pass through each group of pulling rollers 4 in sequence and reciprocate through the heating channels 2 of each layer layer by layer.

[0010] A plurality of steel wire traction rollers 5 are also arranged on the drafting unit 1, the positions of the steel wire traction rollers 5 correspond to the heating channels 2 of each layer of the pre-oxidation furnace 3, and a traction steel wire 6 reciprocates around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com