Environment-friendly single-spray mosaic swimming pool cloth and production process thereof

A production process and technology for swimming pool cloth, applied in the field of environmentally friendly single-spray mosaic swimming pool cloth and its production process, can solve the problems of easy breeding of bacteria and algae, poor hydrostatic pressure resistance, poor color fastness of products, etc. Excellent color fastness to chlorinated water, ensuring physical and mechanical properties, and improving the effect of anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

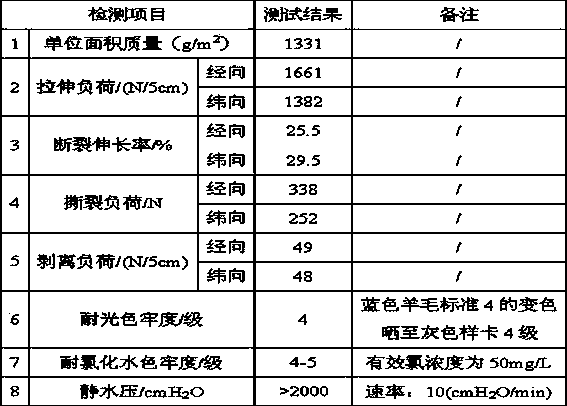

Embodiment 1

[0038]An environmentally friendly single-spray mosaic swimming pool cloth, the swimming pool cloth adopts a polyester warp-knitted biaxial mesh cloth with a linear density of 1000D×1000D, a density of 9×9 threads / inch, and a binding yarn of 66D / 24F as the skeleton material. The surface is laminated with PVC film;

[0039] Wherein, the PVC film is made from the following raw materials by weight: 100 parts by weight of PVC resin powder, 50 parts by weight of diisononyl phthalate, 3 parts by weight of epoxy soybean oil, 20 parts by weight of nano calcium powder, 4 parts by weight of barium zinc stabilizer, 1.8 parts by weight of SHT-115, 0.3 parts by weight of anti-UV agent, and 9 parts by weight of rutile titanium dioxide.

[0040] Since the mosaic swimming pool cloth needs to withstand high water pressure, it is one of the key points of the present invention to select a suitable skeleton material to improve the tensile and tear resistance of the product. In order to improve th...

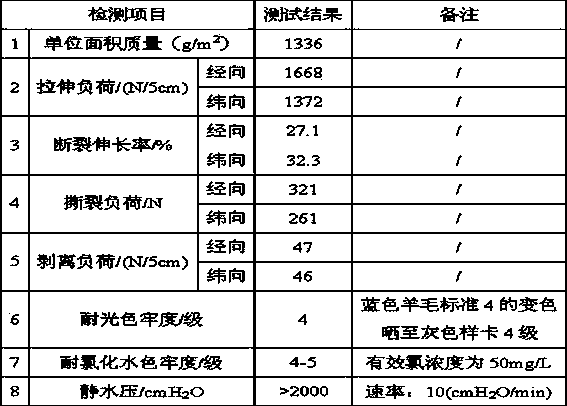

Embodiment 2

[0050] An environmentally friendly single-spray mosaic swimming pool cloth, the swimming pool cloth adopts a polyester warp-knitted biaxial mesh cloth with a linear density of 1000D×1000D, a density of 9×9 threads / inch, and a binding yarn of 66D / 24F as the skeleton material. The surface is laminated with PVC film;

[0051] The dosage of each raw material component of the PVC film is: 100 parts by weight of PVC resin powder, 47 parts by weight of diisononyl phthalate, 4 parts by weight of epoxy soybean oil, 18 parts by weight of nanometer calcium powder, barium zinc stabilizer 3 parts by weight, 0.7 parts by weight of SHT-115, 0.4 parts by weight of anti-UV agent, and 10 parts by weight of rutile titanium dioxide.

[0052] Described ink adopts acrylic resin, wax powder and polyethylene terephthalate resin as ink additive, and each weight percent of described acrylic resin, wax powder, polyethylene terephthalate resin is respectively: 72%, 21%, 7%.

[0053] The thickness of th...

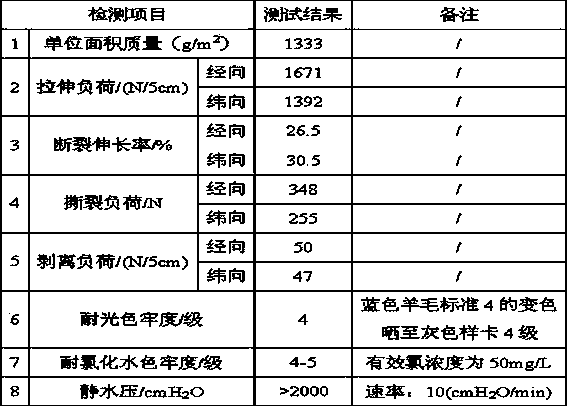

Embodiment 3

[0059] A kind of production technology of environment-friendly single-spray mosaic swimming pool cloth, described production technology comprises PVC film calendering process and product processing technology, and described PVC film calendering process specifically comprises the following steps:

[0060] (1) Ingredients: weigh each raw material according to parts by weight; the dosage of each raw material component of PVC film is: 100 parts by weight of PVC resin powder, 50 parts by weight of diisononyl phthalate, 5 parts by weight of epoxy soybean oil Parts by weight, 20 parts by weight of nano calcium powder, 3 parts by weight of barium zinc stabilizer, 3 parts by weight of SHT-115, 0.5 parts by weight of anti-UV agent, 8 parts by weight of rutile titanium dioxide;

[0061] (2) Stirring: Control the temperature to 130°C, the stirring speed to 750r / min, and the stirring time to 290s; then cool down to 65°C, the stirring speed to 350r / min, and the stirring time to 190s;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com