Anti-slip PVC printing register swimming pool coil floor

A coiled flooring and flower swimming pool technology, applied in swimming pools, floor coverings, lamination, etc., can solve the problems of easy delamination, easy slipping, and printed patterns without three-dimensional effect, so as to improve the anti-slip effect and improve the three-dimensional effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

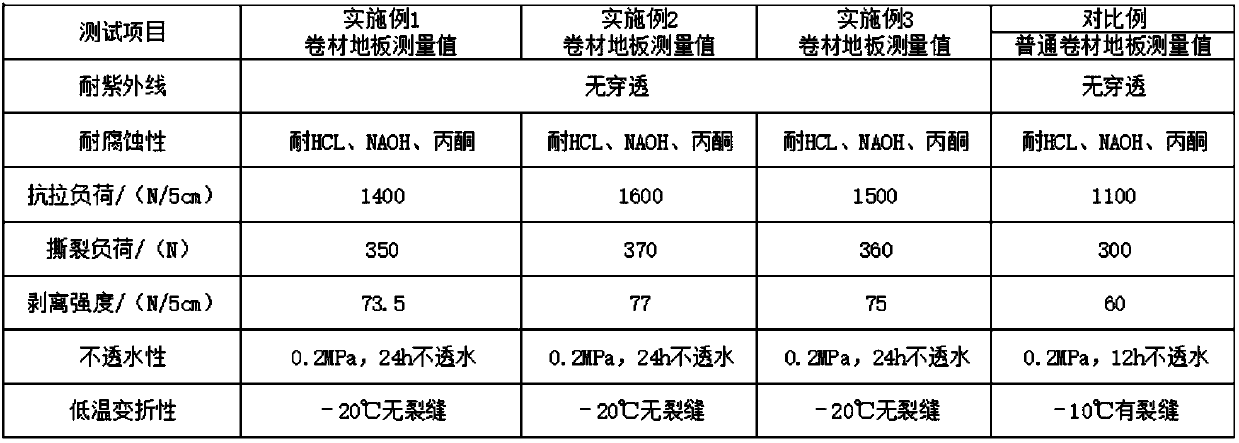

Examples

Embodiment 1

[0036] The non-slip PVC printed facing swimming pool coil floor includes high-strength polyester fiber mesh and PVC film, and the top and bottom surfaces of the high-strength polyester fiber mesh are laminated with a layer of PVC film by hot pressing.

[0037] The PVC adhesive film includes the following raw materials in mass fractions: suspension method-45 parts of polyvinyl chloride resin powder, 24 parts of diisononyl phthalate, 4.5 parts of dioctyl adipate, 1 part of epoxy soybean oil, 1 part of barium-zinc liquid stabilizer, 10 parts of light active calcium carbonate, 0.15 parts of antifungal agent and 1.5 parts of organic toner.

[0038] The preparation method of described PVC film comprises the following steps:

[0039] A1: mixed

[0040] Put the raw materials into the high-speed blender according to the formula, and stir at 100°C for 10 minutes to obtain the molten mixture;

[0041] A2: filter

[0042] The molten mixture obtained in A1 is filtered with a 150-mesh fi...

Embodiment 2

[0067] The non-slip PVC printed facing swimming pool coil floor includes high-strength polyester fiber mesh and PVC film, and the top and bottom surfaces of the high-strength polyester fiber mesh are laminated with a layer of PVC film by hot pressing.

[0068] The PVC adhesive film includes the following raw materials in mass fractions: suspension method-50 parts of polyvinyl chloride resin powder, 25 parts of diisononyl phthalate, 6 parts of dioctyl adipate, 1.5 parts of epoxy soybean oil, 1.5 parts of barium zinc liquid stabilizer, 12 parts of light activated calcium carbonate, 0.2 parts of antifungal agent and 1.8 parts of organic toner.

[0069] The preparation method of described PVC film comprises the following steps:

[0070] A1: mixed

[0071] Put the raw materials into a high-speed blender according to the formula, and stir at a temperature of 100-140°C for 12 minutes to obtain a mixture in a molten state;

[0072] A2: filter

[0073] The molten mixture obtained in...

Embodiment 3

[0098] The non-slip PVC printed facing swimming pool coil floor includes high-strength polyester fiber mesh and PVC film, and the top surface and the ground of the high-strength polyester fiber mesh are respectively hot-pressed and laminated with a layer of PVC film.

[0099] The PVC adhesive film includes the following raw materials in mass fractions: suspension method-55 parts of polyvinyl chloride resin powder, 28 parts of diisononyl phthalate, 7.0 parts of dioctyl adipate, 2.5 parts of epoxy soybean oil, 2.5 parts of barium zinc liquid stabilizer, 15 parts of light activated calcium carbonate, 0.25 parts of antifungal agent and 2.2 parts of organic toner.

[0100] The preparation method of described PVC film comprises the following steps:

[0101] A1: mixed

[0102] Put the raw materials into a high-speed blender according to the formula, and stir for 15 minutes at a temperature of 140°C to obtain a molten mixture;

[0103] A2: filter

[0104] The molten mixture obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear load | aaaaa | aaaaa |

| Tear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com