Wire-drawing screen cloth composite material and preparing method thereof

A technology of composite materials and screen cloth, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, coatings, etc., to solve the problem of air leakage and air tightness, improve air tightness, and solve the effect of bonding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

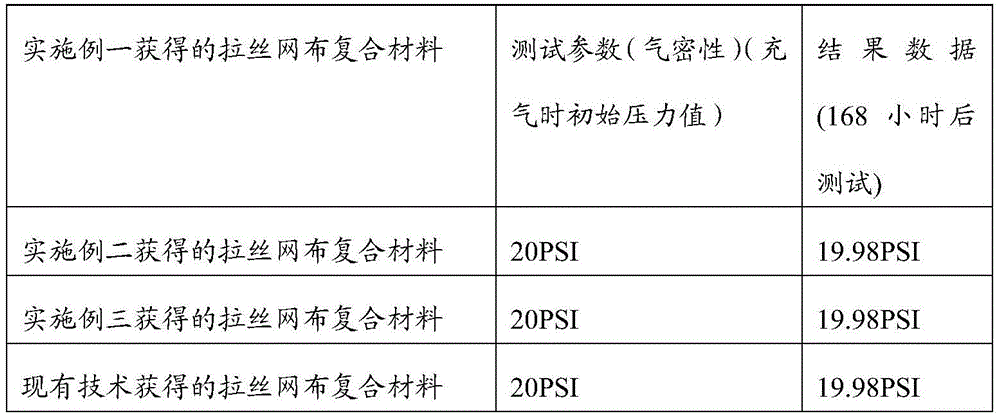

[0022] The beneficial effects of the preparation method of the wire drawing mesh composite material of the present invention are:

[0023] (1) The viscosity of the coating agent is increased from 2000cps in the prior art to 10000-12000cps, so as to prevent the coating agent from penetrating into the middle wire-drawn mesh, thereby solving the bonding problem of the middle wire-drawn mesh;

[0024] (2) Firstly coat the two sides of the wire-drawn mesh with coating agent respectively, and then attach it to the PVC film. The plasticized coating agent also has small pores, which may cause air leakage, but add a layer After the PVC film, because there is no small air hole in the middle of the calendered PVC film, the small air hole of the plasticized coating agent can be blocked, so it can solve the problem of air leakage and air tightness, and has the technical effect of effectively improving the air tightness.

[0025] In the wire drawing mesh composite material of the present in...

Embodiment 1

[0040] The preparation method of the brushed mesh composite material of the present embodiment is to mix 60 parts by weight of diisononyl phthalate or dioctyl phthalate with 95 parts by weight of polyvinyl chloride and 2 parts by weight of stabilizer to form a coating coating agent, the viscosity of the coating agent is 10000cps, the two sides of the drawing mesh cloth are respectively coated with the coating agent, and then the drawing mesh cloth coated with the coating agent is plasticized, and the plasticizing For: the wire-drawn mesh cloth coated with the coating agent is dried sequentially and continuously for four times, the temperature of the four times of drying is 150°C, 155°C, 160°C and 155°C, and the time of the four times of drying is as follows: 30S, 30S, 60S and 30S. The thickness of the PVC film was calendered to 0.3mm by using a calender, and the two sides of the plasticized wire mesh were respectively bonded to the PVC film by a laminating machine to obtain th...

Embodiment 2

[0042] The preparation method of the brushed mesh composite material of the present embodiment is to mix 80 parts by weight of diisononyl phthalate or dioctyl phthalate with 105 parts by weight of polyvinyl chloride and 4 parts by weight of stabilizer to form a coating coating agent, the viscosity of the coating agent is 12000cps, the two sides of the drawing mesh cloth are respectively coated with the coating agent, and then the drawing mesh cloth coated with the coating agent is plasticized, and the plasticizing For: the wire-drawn mesh cloth coated with the coating agent is dried sequentially and continuously for four times, the temperature of the four times of drying is 155°C, 160°C, 165°C and 160°C, and the time of the four times of drying is as follows: 40S, 40S, 80S and 40S. The thickness of the PVC film was calendered to 0.75 mm by using a calender, and the two sides of the plasticized wire mesh were respectively bonded to the PVC film by a laminating machine to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com