PVC granule-spread permeable coiled floor, and its preparation method

A technology of transparent coils and manufacturing methods, which can be applied to building structures, buildings, floors, etc., can solve the problems of poor thermal shear strength, weak composite layers, easy wear and tear of patterns, etc., and achieve wear resistance Strong durability, clear and natural pattern, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

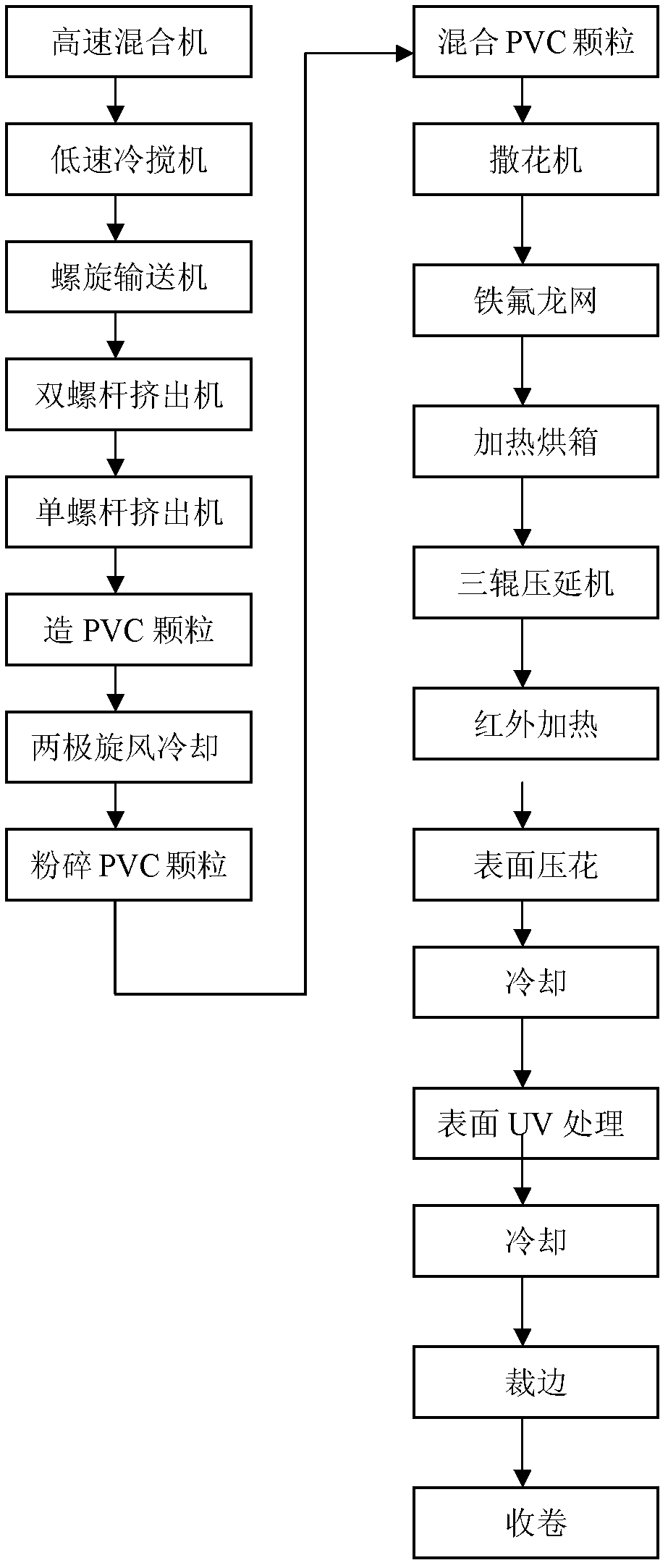

[0020] Such as figure 1 Shown, the preparation method of PVC granule flower permeable coil floor, the method comprises the following process steps:

[0021] (1) PVC 50Kg, DINP 16Kg, CaCO 3 Add 50Kg, heat stabilizer Ca / Zn 1Kg, Ba / Zn 2Kg, modifier ACR-4031Kg, titanium dioxide 3Kg, rose red 0.02Kg, medium chrome yellow 0.016Kg, thick black 0.002kg, etc. into the high-speed mixer and stir. Temperature to 95°C discharge to cold stirred pot. Other color pigments are different.

[0022] (2) The screw conveyor feeds the material into the twin-screw extruder to fully heat, shear and plasticize. Then enter the single-screw extruder for further heating (body 140°C, head 172°C), plasticize, and the exit rotary knife cuts off the pellets (Φ8mm), and finally the red PVC pellets are cooled by two-stage cyclone, Vibrating sieve screening, weighing and bagging for later use.

[0023] (3) PVC granule crushing: Pour Φ8mm PVC granules into a grinder equipped with a 2-3mm aperture sieve for c...

Embodiment 2

[0028] A method for manufacturing a PVC granule sprinkled permeable coil floor, the method comprising the following steps:

[0029] (1) PVC granulation: Polyvinyl chloride resin (PVC) 100Kg, diisononyl phthalate (DINP) 30-35Kg, calcium carbonate 100Kg, Ca / Zn composite heat stabilizer 4Kg, modifier ACR- 403 2Kg, modifier ACR-401 2Kg, titanium dioxide 2Kg, original blue 1Kg, heat-resistant purple 1Kg, thick black 1Kg, rose red 1Kg, medium chrome yellow 1Kg, phthalocyanine green 1Kg, phthalocyanine blue 2Kg, put into the mixer Stir at low speed (300 rpm) for 2 to 3 minutes, then turn to high speed (1000 rpm) and stir for 5 to 6 minutes, then turn to low speed and stir for 2 to 3 minutes when the temperature rises to 110°C. Discharge into the low-speed cold stirring pot, disperse and cool to 20-25°C, then discharge into the storage tank, and then send to the twin-screw extruder by the screw conveyor to fully heat, shear, plasticize, and then enter the single-screw extruder (The t...

Embodiment 3

[0035] A method for manufacturing a PVC granule sprinkled permeable coil floor, the method comprising the following steps:

[0036](1) PVC granulation: polyvinyl chloride resin (PVC) 100Kg, diisononyl phthalate (DINP) 30-35Kg, calcium carbonate 100Kg, Ca / Zn composite heat stabilizer 6Kg, modifier ACR- 403 1Kg, modifier ACR-401 1Kg, titanium dioxide 2Kg, medium chrome yellow 2Kg, phthalocyanine green 2Kg, phthalocyanine blue 2Kg, put into the mixer and stir at low speed (800 rpm) for 2 to 3 minutes, then transfer to Stir at high speed (1200 rpm) for 5-6 minutes, the temperature rises to 95°C, then turn to low-speed stirring for 2-3 minutes again, put the mixed material into a low-speed cold stirring pot, disperse and cool to 20-25°C, and then discharge it into In the storage tank, it is sent to the twin-screw extruder by the screw conveyor to fully heat, shear, and plasticize, and then enter the single-screw extruder (the temperature of the body is 130-145°C, and the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com