Preparation method and application method of phthalates molecular imprinted magnetic materials through dual-virtual template

A phthalate ester and virtual template technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of insufficient selectivity of solid phase extraction, complex matrix components, and unsatisfactory Requirements for the separation and enrichment of PAEs components and other issues, to achieve good specific recognition and selectivity, simple and convenient preparation process, and conducive to rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030](1) Mix 5g of graphite powder and 5g of sodium nitrate with 230mL of concentrated sulfuric acid in an ice bath, slowly add 40g of potassium permanganate, react for 2 hours, and control the temperature of the reaction solution not to exceed 10°C; remove the ice bath, and transfer the mixture to In a constant temperature water bath at 35°C, stir and react for 2 hours; raise the temperature of the water bath to 95°C and gradually add 230mL ultrapure water, keep the reaction for 40min to increase the degree of oxidation of the product; after the reaction, place it to cool to room temperature, then Add ultrapure water to 1000mL, and dropwise add hydrogen peroxide with a mass fraction of 30% until no bubbles are formed; let it settle, discard the supernatant, wash with deionized water and absolute ethanol three times respectively, and store at 70°C Vacuum drying yields graphene oxide (GO).

[0031] (2) 0.3g GO, 3.52g FeCl 3 ·6H 2 O and 1.81 g FeSO 4 ·7H 2 O was dissolved i...

Embodiment 2

[0037] Carry out various index experiments to the material obtained in Example 1.

[0038] 20 mg of the material obtained in Example 1 was added to 20 mL of solutions containing 20 mg / L PAEs at different pH values to investigate the effect of pH value on the adsorption effect of PAEs. The results showed that the adsorption amount was the largest when the pH was around 7, so the subsequent adsorption experiments were all carried out under neutral conditions.

[0039] 20 mg of the material obtained in Example 1 was added to 20 mL of a pH=7 solution containing 20 mg / L PAEs, and an adsorption reaction occurred in a constant temperature oscillator at 25°C to investigate the effect of adsorption time on the adsorption effect. The results showed that after 120 minutes, the adsorption reached equilibrium, the adsorption process obeyed the second-order kinetics, and the mass transfer process of the adsorbed mass was mainly controlled by the chemical adsorption mechanism.

[0040] 20...

Embodiment 3

[0043] The material obtained in Example 1 was used for the solid phase extraction separation and enrichment of trace PAEs in the solution.

[0044] Add 20mg of the material to 100mL of PAEs solution containing 10μg / L, adjust the pH to 7, shake in a constant temperature oscillator at 25°C and 200rpm for 30min, and perform solid phase extraction. After the extraction, the material containing PAEs was sucked to the bottom of the reaction vessel with a magnet, and the supernatant was discarded. Then add 3mL absolute ethanol solution and shake and elute at 250rpm for 5min, magnetically separate, measure the concentration of PAEs in the upper eluent with GC-MS, do 3 groups of parallel experiments simultaneously, adopt internal standard method (with benzyl benzoate as internal standard) to calculate the recovery of PAEs.

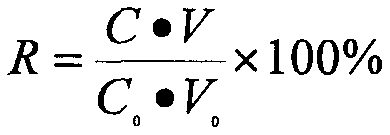

[0045] The calculation formula of the recovery rate is as follows:

[0046]

[0047] where C 0 and C are the concentrations of PAEs in the solution before so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com